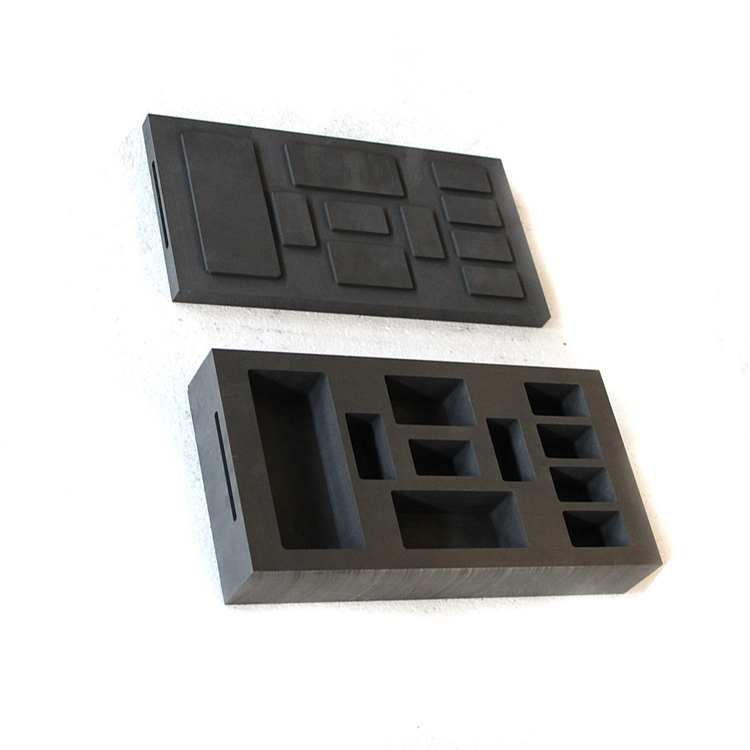

NkeCVD SiC mkpuchiCC Composite Mold, Carbon-Carbon Composite Mold, C/C Mold from vet-china bụ ihe arụ ọrụ dị elu emebere maka ụlọ ọrụ na-achọ ka okpomọkụ na nguzogide kemịkalụ dị elu. Nkecarbon-carbon mejupụtaraỌdịdị, kwalitere na mkpuchi CVD SiC (Silicon Carbide), na-enye ogologo ndụ pụrụ iche na nkwụsi ike n'okpuru oke okpomọkụ, na-eme ka ọ dị mma maka ngwa ndị dị ka mmepụta semiconductor, ikuku ikuku, na ụgbọ ala.

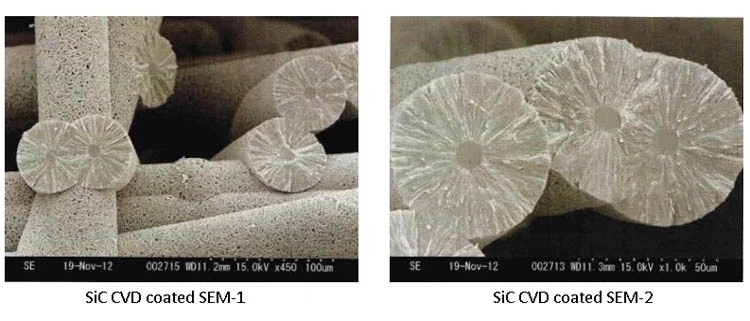

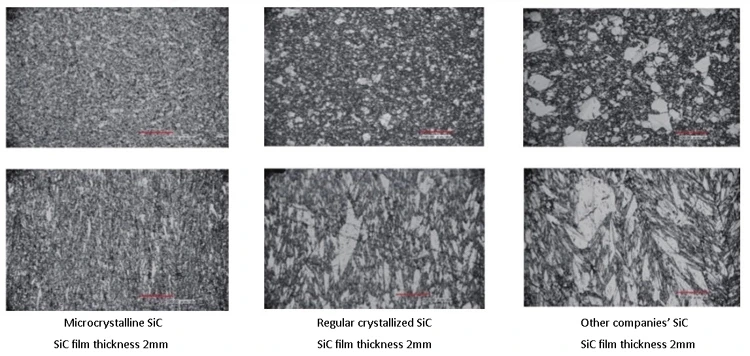

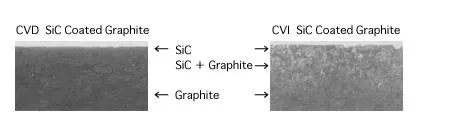

NkeCVD SiC mkpuchina-enye nguzogide dị ịrịba ama nke iyi na oxidation, na-agbatị ndụ ndụ nke ebu ma hụ na arụmọrụ a pụrụ ịdabere na ya na gburugburu ebe siri ike. Teknụzụ mkpuchi mkpuchi a dị elu na-emekwa ka isi ike dị elu, na-echebe ihe ebu n'oge usoro okpomọkụ dị elu yana igbochi nrụrụ ma ọ bụ mmebi. Ụdị vet-china dị mma nke ukwuu maka ụlọ ọrụ na-ejiCVD SiC yiri mgbaakana components, na-enye ngwọta kachasị mma maka ịmepụta ihe dị elu.

Na mgbakwunye na mkpuchi SiC, iheCVD TaC mkpuchiA pụkwara itinye ya n'ọrụ iji kwalite nguzogide kemịkalụ, na-eme ka ọkpụkpụ ahụ dị iche iche maka ngwa dị iche iche na-achọ nchebe pụọ na ihe ndị na-emerụ emerụ. Ọkachamara Vet-china na CVD SiC na C/C composites na-eme ka a mara na ejiri nkenke arụ ọrụ nke ọ bụla, na-ebuga arụmọrụ kachasị elu na mpaghara ụlọ ọrụ mmepụta ihe yana teknụzụ.

Nchikota nke CVD SiC na carbon-carbon composite material na-eme ka o doo anya na CVD SiC Coating CC Composite Mold, Carbon-Carbon Composite Mold, C / C Mold na-emebiga ihe ókè na usoro ndị metụtara oke okpomọkụ, mkpughe kemịkalụ, na nrụgide n'ibu, na-enye ndị ọrụ ihe ngwọta na-adịgide adịgide, nke a pụrụ ịdabere na ya.

Isi atụmatụ:

1. Nguzogide oxidation dị elu:

Nguzogide oxidation ka dị ezigbo mma mgbe okpomọkụ dị elu dị ka 1600 C.

2. Nnukwu ịdị ọcha: nke a na-eme site na ntinye ikuku kemịkalụ n'okpuru ọnọdụ chlorination dị elu.

3. Nguzogide nbibi: elu ike, kọmpat elu, ezigbo ahụ.

4. Nguzogide corrosion: acid, alkali, nnu na organic reagents.

Nkọwa bụ isi nke mkpuchi CVD-SIC:

| SiC-CVD | ||

| Njupụta | (g/cc)

| 3.21 |

| Ike mgbanwe | (Mpa)

| 470 |

| Mgbasa ọkụ ọkụ | (10-6/K) | 4

|

| Thermal conductivity | (W/mK) | 300

|