-

Silicon nitride – structural ceramics with the best overall performance

Special ceramics refers to a class of ceramics with special mechanical, physical or chemical properties, the raw materials used and the required production technology are greatly different from ordinary ceramics and development. According to the characteristics and uses, special ceramics can be d...Read more -

Effect of sintering on properties of zirconia ceramics

As a kind of ceramic material, zirconium has high strength, high hardness, good wear resistance, acid and alkali resistance, high temperature resistance and other excellent properties. In addition to being widely used in the industrial field, with the vigorous development of the denture industry ...Read more -

Semiconductor parts – SiC coated graphite base

SiC coated graphite bases are commonly used to support and heat single crystal substrates in metal-organic chemical vapor deposition (MOCVD) equipment. The thermal stability, thermal uniformity and other performance parameters of SiC coated graphite base play a decisive role in the quality of epi...Read more -

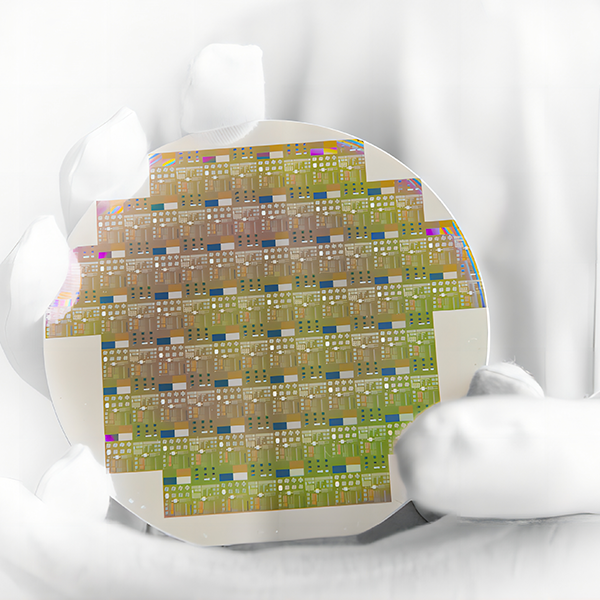

Why Silicon as a semiconductor chip?

A semiconductor is a material whose electrical conductivity at room temperature is between that of a conductor and an insulator. Like copper wire in everyday life, aluminum wire is a conductor, and rubber is an insulator. From the point of view of conductivity: semiconductor refers to a conductiv...Read more -

Effect of sintering on properties of zirconia ceramics

Effect of sintering on properties of zirconia ceramics As a kind of ceramic material, zirconium has high strength, high hardness, good wear resistance, acid and alkali resistance, high temperature resistance and other excellent properties. In addition to being widely used in the industrial field,...Read more -

Semiconductor parts – SiC coated graphite base

SiC coated graphite bases are commonly used to support and heat single crystal substrates in metal-organic chemical vapor deposition (MOCVD) equipment. The thermal stability, thermal uniformity and other performance parameters of SiC coated graphite base play a decisive role in the quality of epi...Read more -

Breakthrough sic growth key core material

When silicon carbide crystal grows, the “environment” of the growth interface between the axial center of the crystal and the edge is different, so that the crystal stress on the edge increases, and the crystal edge is easy to produce “comprehensive defects” due to the inf...Read more -

How is reaction-sintered silicon carbide produced?

Reaction sintering silicon carbide is an important method to produce high performance ceramic materials. This method uses heat treatment of carbon and silicon sources at high temperatures to make them react to form silicon carbide ceramics. 1. Preparation of raw materials. The raw materials of r...Read more -

Silicon carbide crystal boat, innovative material silicon carbide brings strong power

Silicon carbide crystal boat is a very novel technology, which has changed the traditional way of manufacturing. It is able to combine silicon carbide and others to form a very tight structure, which can effectively improve the efficiency of the manufacturing process, and can greatly improve the ...Read more -

Application and market of tantalum carbide coating

Tantalum carbide hardness, high melting point, high temperature performance, mainly used as a cemented carbide additive. The thermal hardness, thermal shock resistance and thermal oxidation resistance of cemented carbide can be significantly improved by increasing the grain size of tantalum carbi...Read more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur