High Quality for Electric Brake Vacuum Pump In Rotary Vane - CVD furnace for SiC coating – VET Energy Detail:

CVD furnace (SiC、BN)

Furnace used for anti-oxidation coating, matrix material character change and etc. by using Silicohydride gas source. It has both horizontal and vertical structures.

Application: SiC coating for C/C composite material, SiC coating for graphite, SiC, BN and ZrC coating for fiber and etc.

Specification

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Model | Working Zone Size(W × H × L) (mm) | Max. Temperature (°C) | Temperature Uniformity (°C) | Ultimate Vacuum (Pa) | Pressure Increase Rate (Pa/h) |

| Horizontal structure | |||||

| LFH-6900-SiC | 600 × 600 × 900 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFH-10015-SiC | 1000 × 1000 × 1500 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFH-1220-SiC | 1200×1200×2000 | 1500 | ±10 | 1-100 | 0.67 |

| LFH-1530-SiC | 1500×1500×3000 | 1500 | ±10 | 1-100 | 0.67 |

| LFH-2535-SiC | 2500×2000×3500 | 1500 | ±10 | 1-100 | 0.67 |

| Vertical structure | |||||

| LFV-D3050-SiC | φ300×500 | 1500 | ±5 | 1-100 | 0.67 |

| LFV-D6080-SiC | φ600×800 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFV-D8120-SiC | φ800×1200 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFV-D11-SiC | φ1100×2000 | 1500 | ±10 | 1-100 | 0.67 |

| LFV-D26-SiC | φ2600×3200 | 1500 | ±10 | 1-100 | 0.67 |

Technical Features

1. Using the most advanced control technology, it can precise control the MTS flow and pressure, the deposition flow is stable and pressure fluctuate in narrow range;

2. Special designed deposition chamber with good sealing effect and great anti-contamination performance;

3. Using multiple deposition channels with uniformity gas flow, without deposition dead corner and perfect deposition surface;

4. It has treatment for the high corrosive gas, flammable and explosive gas , solid dust and low melting point sticky materials during the deposition process;

5. Using newly designed corrosion resistant vacuum pump which has long continuous working hours and low maintenance rate.

Optional Configuration of CVD Furnace

1. Furnace door: screw/hydraulic/manual elevation type;swing opening/parallel opening(large size furnace door); manual tight/ auto lock-ring tight

2. Furnace vessel: all carbon steel/inner layer stainless steel/all stainless steel

3. Furnace hot zone: soft carbon felt/soft graphite felt/rigid composite felt/CFC

4. Heating element and muffle: isostatic press graphite/high purity, strength and density graphite/fine size graphite

5. Process gas system: volume/mass flow-meter

6.Thermocouple: K type/N type/C type/S type

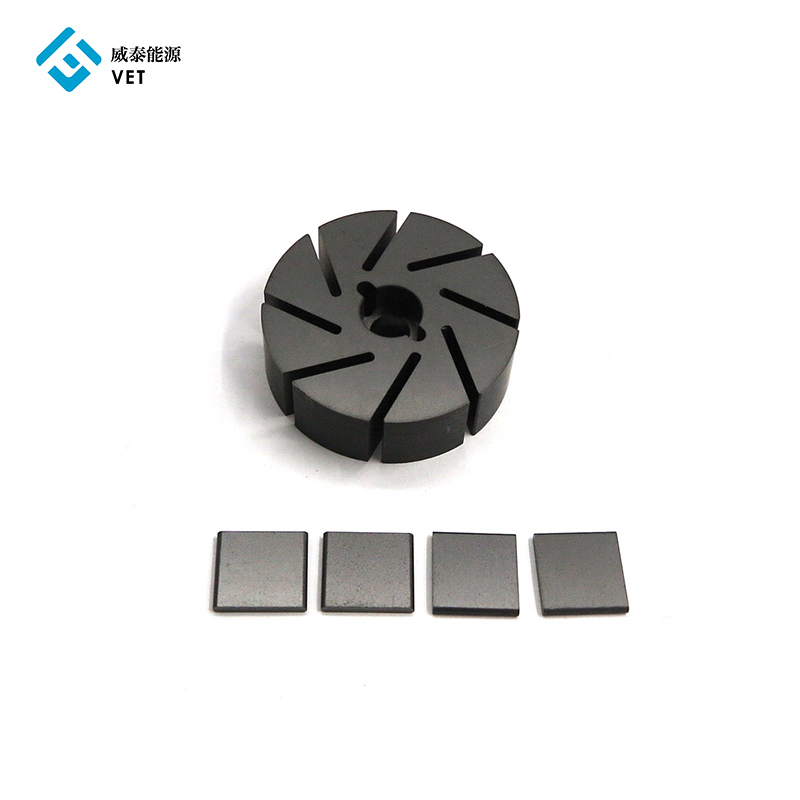

Product detail pictures:

Related Product Guide:

Live Updates: Officials Say They Can’t Risk Another Grenfell Fire And Evacuate Five Towers BuzzFeed News BuzzFeed Reviews BuzzFeed Tasty BuzzFeed Goodful BuzzFeed Bring Me BuzzFeed As Is BuzzFeed News Homepage Search BuzzFeed Search BuzzFeed BuzzFeed News | Side Spray Kits

Turkish police fire water cannon at pro-Kurdish election posters: report | Fire Water Cannon

High Quality for Electric Brake Vacuum Pump In Rotary Vane - CVD furnace for SiC coating – VET Energy, The product will supply to all over the world, such as: , , ,

-

Top Quality Carbon Graphite Plates - Graphite ...

-

Wholesale Discount High Conductivity Graphite S...

-

High reputation Power Brake Booster Auxiliary P...

-

Reasonable price for Electrode Graphite Rod - ...

-

Factory supplied Antimony Graphite Ring - Hyun...

-

China wholesale Graphite Plate - Hot New Produ...