-

What are the reactions of the industry to the green hydrogen standard announced by the EU?

The EU’s newly published enabling law, which defines green hydrogen, has been welcomed by the hydrogen industry as bringing certainty to the investment decisions and business models of EU companies. At the same time, the industry is concerned that its “stringent regulations” wi...Read more -

Content of two enabling Acts required by the Renewable Energy Directive (RED II) adopted by the European Union (EU)

The second authorization bill defines a method for calculating life-cycle greenhouse gas emissions from renewable fuels from non-biological sources. The approach takes into account greenhouse gas emissions throughout the life cycle of fuels, including upstream emissions, emissions associated wit...Read more -

Content of two enabling Acts required by the Renewable Energy Directive (RED II) adopted by the European Union (I)

According to a statement from the European Commission, the first enabling Act defines the necessary conditions for hydrogen, hydrogen-based fuels or other energy carriers to be classified as renewable fuels of non-biological origin (RFNBO). The bill clarifies the principle of hydrogen “addi...Read more -

The European Union has announced what is the green hydrogen standard?

In the context of carbon neutral transition, all countries have high hopes for hydrogen energy, believing that hydrogen energy will bring great changes to industry, transportation, construction and other fields, help adjust the energy structure, and promote investment and employment. The Europea...Read more -

Applications and markets of tantalum carbide coatings

Tantalum carbide hardness, high melting point, high temperature performance, mainly used as a hard alloy additive. The thermal hardness, thermal shock resistance and thermal oxidation resistance of cemented carbide can be improved significantly by increasing the grain size of tantalum carbide. Fo...Read more -

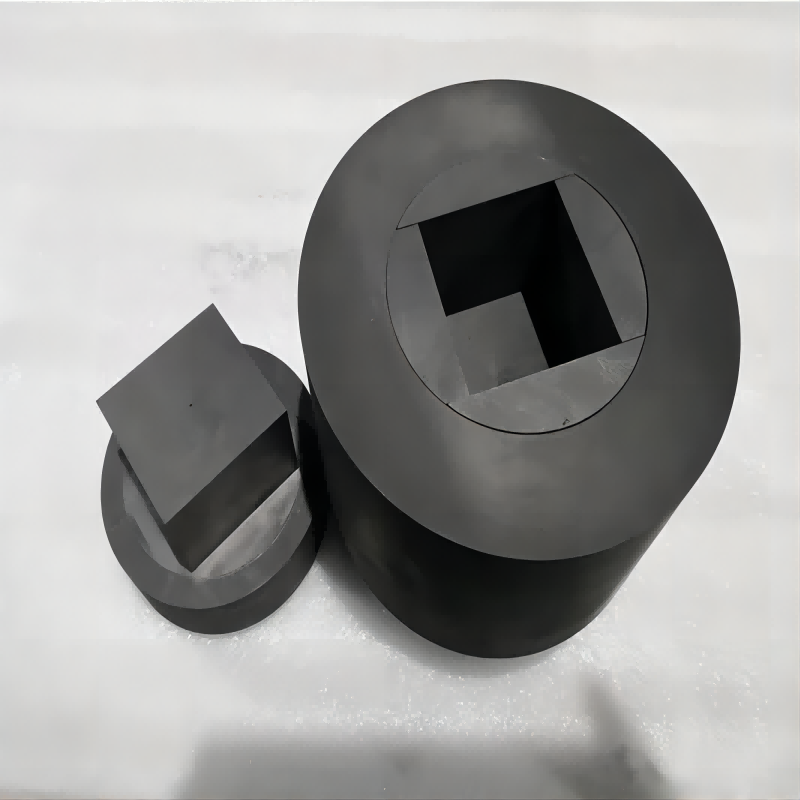

An overview of graphite disks

SIC coated stone grinding base has the characteristics of high temperature resistance, oxidation resistance, high purity, acid, alkali, salt and organic reagents, and stable physical and chemical function. Compared with high purity graphite, high purity graphite at 400℃ beginning intense oxidatio...Read more -

1000 kW diesel generator for emergency

Beijing Woda Power Technology Co.. Ltd is a professional diesel generator set manufacturer with a history of more than 14 years. We have our own professional production lines, including open type diesel generator, silent generator, mobile diesel generator. etc. Rural areas are generally far away...Read more -

High speed diamond wire cutting hard brittle material cold cutting processing method

Graphite carbon carbon ceramic glass steel fiber composite materials carbon fiber composite materials and other hard and brittle materials, the use of diamond wire cutting processing, get twice the result with half the effort. Whether it is the processing of graphite mold, graphite square, graph...Read more -

Properties and application value of SIC ceramics

In the 21st century, with the development of science and technology, information, energy, materials, biological engineering has become the four pillars of the development of today’s social productivity, silicon carbide due to stable chemical properties, high thermal conductivity, thermal ex...Read more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur