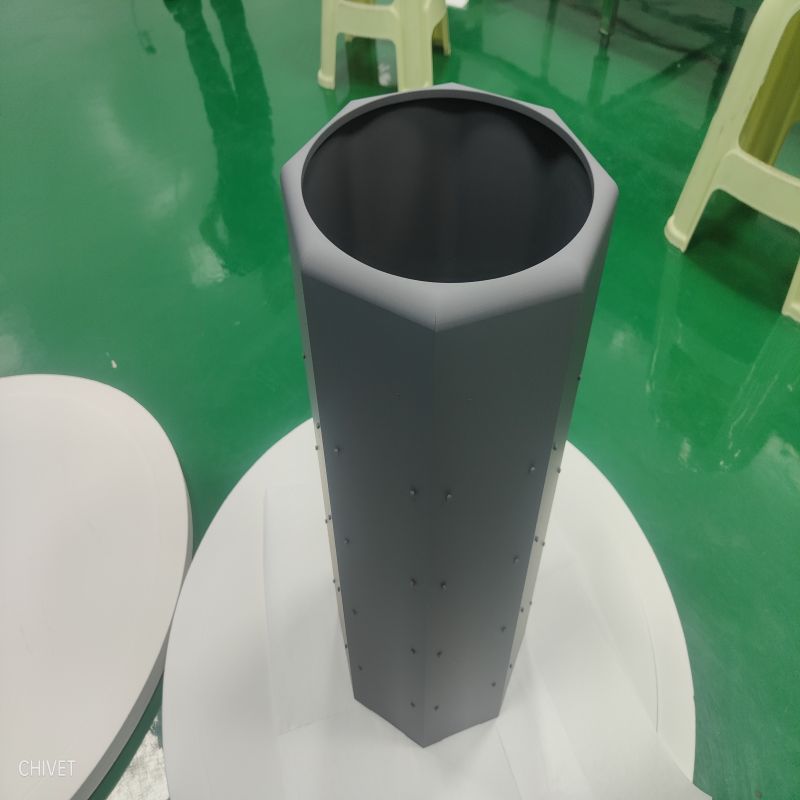

OEM Manufacturer Coated Process Graphite Products – SiC Coated Barrel Susceptor – VET Energy Detail:

Product Description

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer.

Main features:

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity : made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coating

|

SiC-CVD Properties |

||

| Crystal Structure | FCC β phase | |

| Density | g/cm ³ | 3.21 |

| Hardness | Vickers hardness | 2500 |

| Grain Size | μm | 2~10 |

| Chemical Purity | % | 99.99995 |

| Heat Capacity | J·kg-1 ·K-1 | 640 |

| Sublimation Temperature | ℃ | 2700 |

| Felexural Strength | MPa (RT 4-point) | 415 |

| Young’ s Modulus | Gpa (4pt bend, 1300℃) | 430 |

| Thermal Expansion (C.T.E) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |

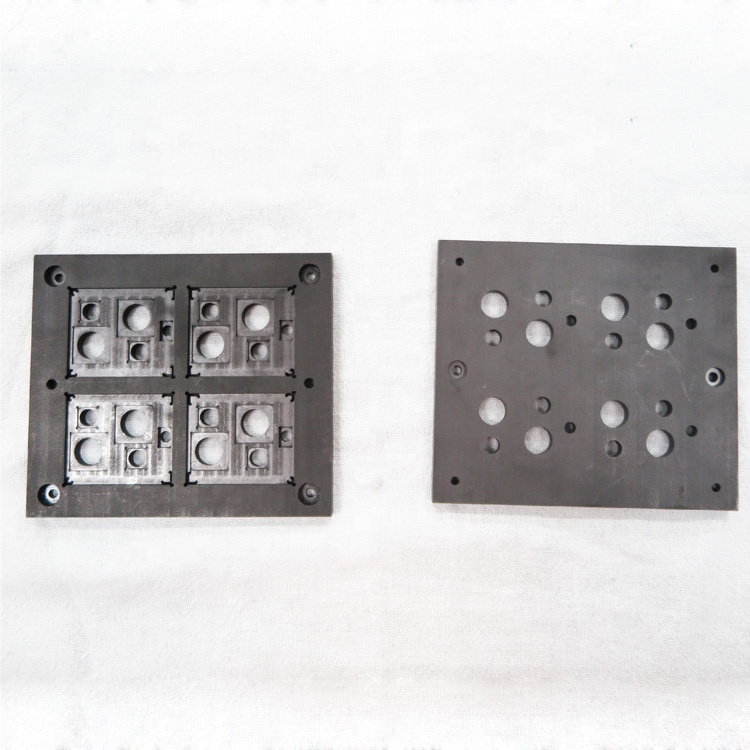

Product detail pictures:

Related Product Guide:

FDIC 2014: Exhibits Exceed Expectations | Fire Water Cannon

How to Weather Model Kits: Everything You Need to Create Realistic Weathering Effects on Plastic Model Kits | Fire Water Cannon

OEM Manufacturer Coated Process Graphite Products – SiC Coated Barrel Susceptor – VET Energy, The product will supply to all over the world, such as: , , ,

-

OEM/ODM Manufacturer Silicon Carbide Coating Pr...

-

Best quality Graphite Boat - Factory directly ...

-

2019 High quality Flexible Graphite Foil - Lat...

-

Good Wholesale VendorsGraphite Casting Mold - ...

-

Good quality Rigid Carbon Felt - High strength...

-

Excellent quality Rigid Graphite Felt - Infini...