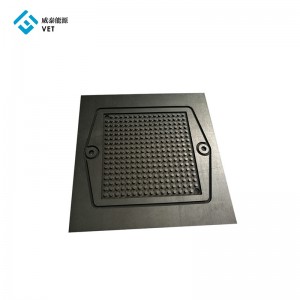

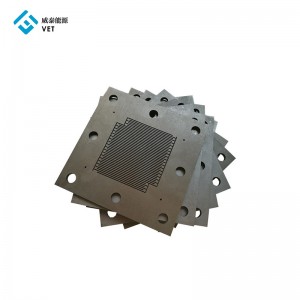

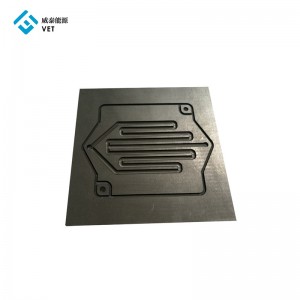

Graphite Bipolar Plate for Hydrogen Fuel Cell,

Bipolar Plates, fuel cell Graphite bipolar plate, Graphite Bipolar Plate, Graphite Bipolar Plate for Hydrogen Fuel Cell, Graphite Electrode Plate,

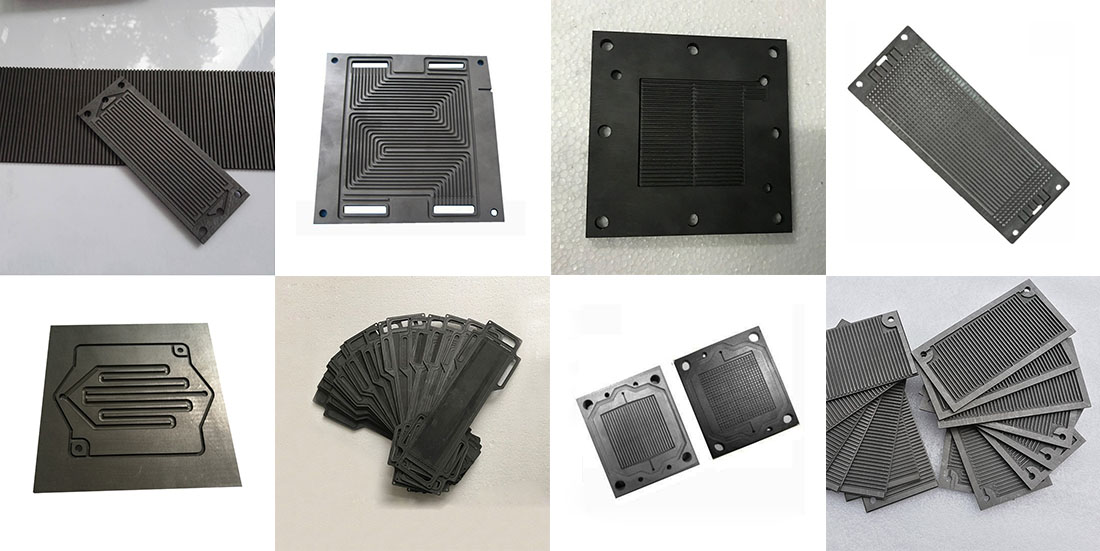

We have developed cost- effective graphite bipolar plates for PEMFC which requires the use of advanced bipolar plates with high electrical conductivity and good mechanical strength. Our bipolar plates allow fuel cells to operate at high temperatures and have excellent electrical and thermal conductivity.

We offer the graphite material with impregnated resin in order to achieve gas impermeability and high strength. But the material retains the favorable properties of graphite in terms of high electrical conductivity and high thermal conductivity.

We can machine the bipolar plates on both sides with flow fields, or machine single side or provide unmachined blank plates as well. All graphite plates could be machined as per your detailed design.

Graphite Bipolar Plates Material Datasheet:

| Material | Bulk Density | Flexural Strength |

Compressive Strength | Specific Resistivity | Open Porosity |

| GRI-1 | 1.9 g/cc min | 45 Mpa min | 90 Mpa min | 10.0 micro ohm.m max | 5% max |

| More grades of graphite materials are available to select according to specific application. | |||||

Features:

- Impermeable to gases ( hydrogen and oxygen)

- Ideal electrical conductivity

- A balance between conductivity, strength, size and weight

- Resistance to corrosion

- Easy to produce in bulk Features:

- Cost-effective

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

-

Renewable Design for China Stainless Steel Smal...

-

electrolytic graphite plate Bipolar Plate for H...

-

High Quality for Anti Oxidation Resistant Carbo...

-

Excellent quality China Bearing Sleeve Plugged ...

-

Manufactur standard China Yutong Electric Vacuu...

-

Manufacturing Companies for High Quality Graphi...