1. Good processing performance.

2. Compared with metal materials, graphite has a lower density and excellent mechanical processing performance.

3. Thermal stability: under the protection of inert gas, he can work at 3000 degrees or even higher.

4. Low expansion rate: even in the case of rapid heating, the low thermal expansion rate can ensure that the graphite size remains unchanged.

5. Good chemical resistance: graphite has good chemical stability, such as acid, alkali resistance and organic solvents at room temperature.

Applications

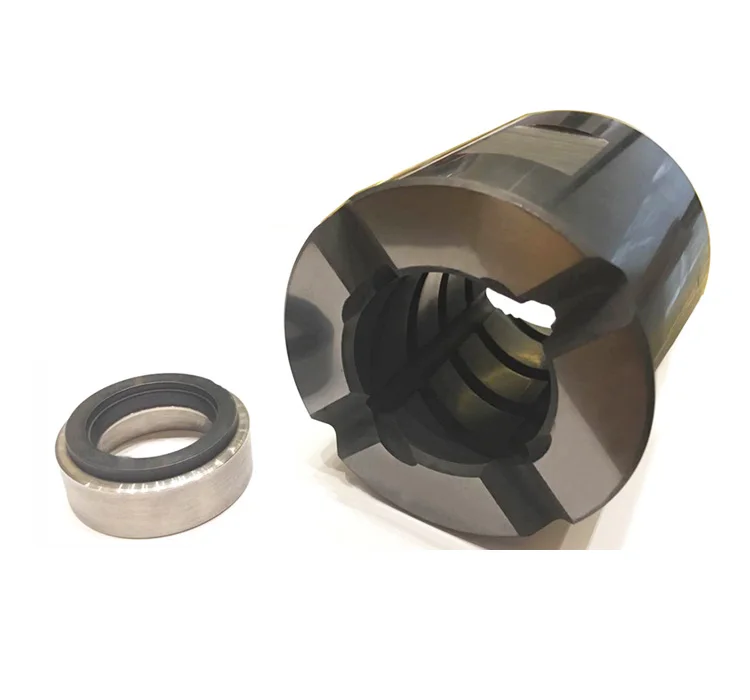

1.Bearings and seals in pumps. Turbines and Motors.

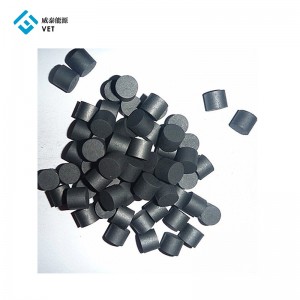

2.Used in continuous casting systems for making shaped steel, cast iron, copper, aluminum.

3.Sintering molds for cemented carbides ,diamond tools,electronic components.

4.Electrodes for EDM. Heaters. Heat shields. Crucibles. Boats in some industrial furnaces

(such as furnaces for pulling monocrystalline silicon or optical fibers).

and so on.

Product design and processing: provide drawings or samples, we make graphite products according to your requirements.

-

Antimony Alloy Graphite Bushings/ Bearing

-

Best selling carbon graphite bearings bushes

-

China Graphite Bearing Manufacturer Carbon Bush...

-

Factory price self-lubricant refractory carbon ...

-

Factory price Self-lubricated Carbon-Graphite P...

-

Good graphite bearing flexible bushing factory ...

-

Good Quality Graphite Bearing Bush And Sleeve

-

Graphite Ring for lubrication

-

Graphite Bushing/Bush Bearings For Mechanical Sale

-

Graphite Oil-Free Bronze Bearing

-

Graphite Solid Self Lubricating Oil Bearing,gra...

-

High Density Isostatic Carbon Graphite Bearing ...

-

High Density Isostatic Carbon Graphite Bearing ...

-

High density plyweight graphite bearings

-

High Quality China Oxidation Resistant Carbon G...

-

High Quality Mould Die Guide Bush, Graphite Oil...