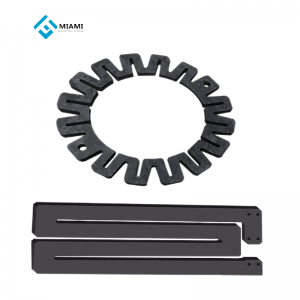

The hot field system of single crystal drawing furnace is mainly used in the long crystal and drawing process of single crystal silicon in photovoltaic industry and semiconductor industry, and is the key equipment for preparing single crystal silicon. The company's products mainly include various specifications of support ring, crucible, pot holder, flow guide cylinder, insulation cylinder, heater, etc., which are the key components of the hot field system of single crystal drawing furnace. The large-size thermal field components of the company have played a supporting role in the large-diameter development of monocrystalline silicon rods. At the same time, the carbon matrix composite thermal field components greatly improve the security of the thermal field system, improve the rate of crystal drawing, significantly reduce the operation power of single crystal drawing furnace, and play a great role in promoting energy saving and consumption reduction.

-

Factory made hot-sale China High Heat Resistanc...

-

Factory Cheap High Density Graphite Heating Ele...

-

Drone 25v Hydrogen Powered Fuel Cell 2000w Hydr...

-

Super Purchasing for Electric Micro Vacuum Pump...

-

Hot Sale for Customized Artificial Anode Graphi...

-

Price Sheet for China Direct Supply High Conduc...