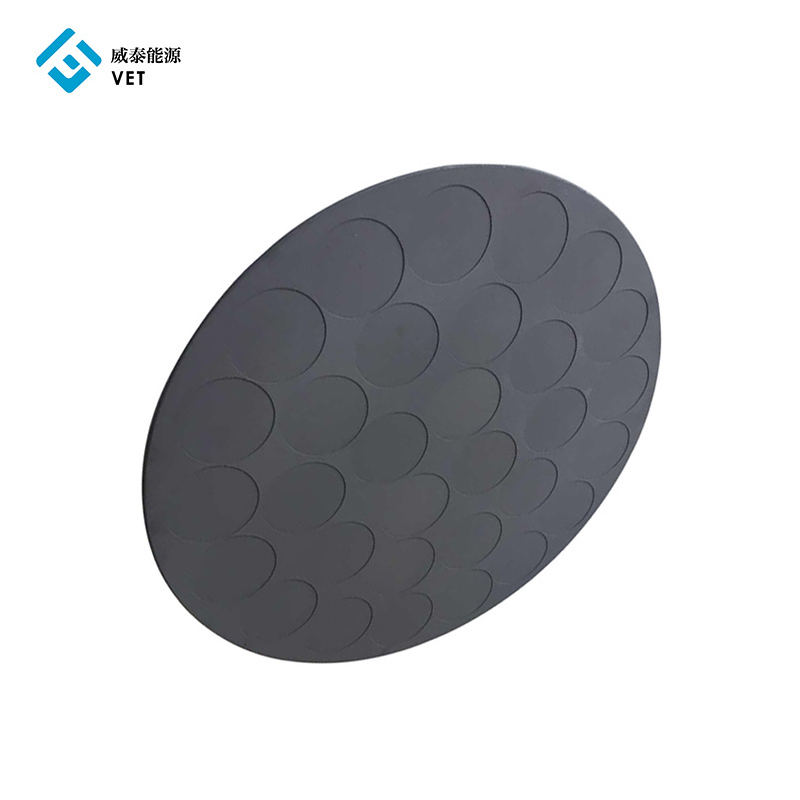

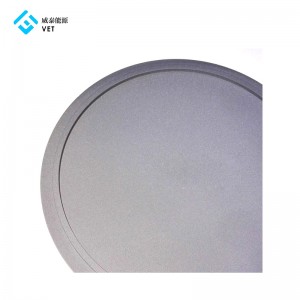

SiC coating/coated of Graphite substrate for Semiconductor, Graphite Trays,Sic Graphite epitaxy susceptors,

Carbon supplies susceptors, epitaxy susceptors, Graphite Susceptors, SiC Epitaxy, support substrates,

SiC Coated Graphite Carriers

We maintain very close tolerances when applying the SiC coating, using high-precision machining to ensure a uniform susceptor profile. We also produce materials with ideal electrical resistance properties for use in inductively heated systems. All finished components come with a purity and dimensional compliance certificate.

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer. The SIC formed is firmly bonded to the graphite base, giving the graphite base special properties, thus making the surface of the graphite compact, Porosity-free, high temperature resistance, corrosion resistance and oxidation resistance.

CVD process delivers extremely high purity and theoretical density of SiC coating with no porosity. What’s more, as silicon carbide is very hard, it can be polished to a mirror-like surface. CVD silicon carbide (SiC) coating delivered several advantages including ultra-high purity surface and extremely wear durability. As the coated products have great performance in high vacuum and high temperature circumstance, they are ideal for applications in semiconductor industry and other ultra-clean environment. We also provide pyrolytic graphite (PG) products.

Main features:

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity: made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coatings:

|

SiC-CVD |

||

| Density |

(g/cc)

|

3.21 |

| Flexural strength |

(Mpa)

|

470 |

| Thermal expansion |

(10-6/K) |

4

|

| Thermal conductivity |

(W/mK) |

300 |

Application: CVD silicon carbide coating has been applied in semiconductor industries already, such as MOCVD tray, RTP and oxide etching chamber since silicon nitride has great thermal shock resistance and can withstand high energy plasma.

-Silicon carbide is widely used in semiconductor and coating.

Supply Ability:

10000 Piece/Pieces per Month

Packaging & Delivery:

Packing:Standard & Strong Packing

Poly bag + Box + Carton + Pallet

Port:

Ningbo/Shenzhen/Shanghai

Lead Time:

| Quantity(Pieces) | 1 – 1000 | >1000 |

| Est. Time(days) | 15 | To be negotiated |

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

-

Graphite heater Silicon carbide (SiC) SiC coati...

-

China Manufacturer SiC Coated Graphite MOCVD Ep...

-

Customized Graphite Heater for Semiconductor Si...

-

CVD SiC Coated Carbon-carbon Composite CFC Boat...

-

CVD sic coating carbon-carbon composite mould

-

CVD sic coating c-c composite rod,silicon carbi...

-

High temperature resistance durable Silicon rod...

-

Mechanical Carbon Graphite Bush Rings,Silicone ...

-

Refractory Ceramic Bonded Silicon Carbide SiC C...

-

oil resistance SIC thrust bearing,Silicon bearing

-

SiC Coated Graphite Base Carriers