We’re going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Fast delivery China Hot Sale High Purity Graphite Material 30-99.9% Extruded Graphite Rod, In a word, when you choose us, you choose a great life. Welcome to go to our manufacturing facility and welcome your purchase! For further inquiries, make sure you do not wait to contact us.

We’re going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for China Extruded Graphite Rod, Graphite Rod, Our business activities and processes are engineered to make sure our customers have access to widest range of products and solutions with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. Now we have people who embrace tomorrow, have vision, love stretching their minds and heading far beyond what they thought was achievable.

Carbon / carbon composites (hereinafter referred to as “C / C or CFC”) is a kind of composite material which is based on carbon and reinforced by carbon fiber and its products (carbon fiber preform). It has both the inertia of carbon and the high strength of carbon fiber. It has good mechanical properties, heat resistance, corrosion resistance, friction damping and thermal and electrical conductivity characteristics

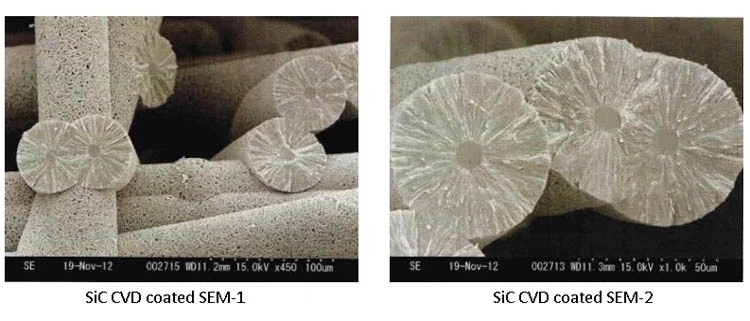

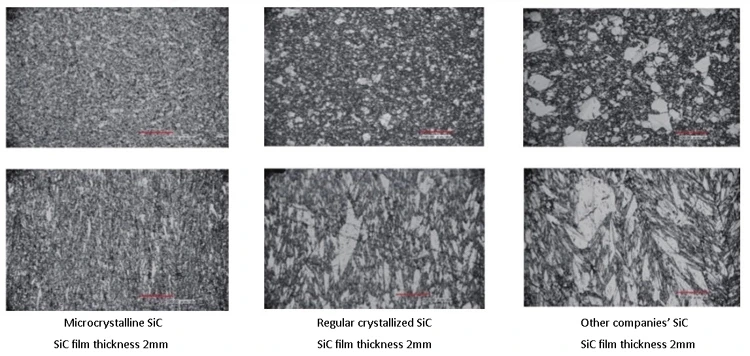

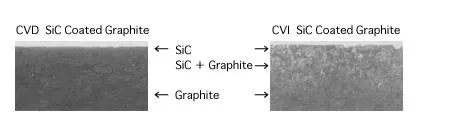

CVD-SiC coating has the characteristics of uniform structure, compact material, high temperature resistance, oxidation resistance, high purity, acid&alkali resistance and organic reagent, with stable physical and chemical properties.

Compared with high-purity graphite materials, graphite begins to oxidize at 400C, which will cause a loss of powder due to oxidation, resulting in environmental pollution to peripheral devices and vacuum chambers, and increase impurities of high-purity environment.

However, SiC coating can maintain physical and chemical stability at 1600 degrees, It is widely used in modern industry, especially in semiconductor industry.

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer. The SIC formed is firmly bonded to the graphite base, giving the graphite base special properties, thus making the surface of the graphite compact, Porosity-free, high temperature resistance, corrosion resistance and oxidation resistance.

Main features:

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity: made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coatings:

|

SiC-CVD |

||

| Density |

(g/cc)

|

3.21 |

| Flexural strength |

(Mpa)

|

470 |

| Thermal expansion |

(10-6/K) |

4

|

| Thermal conductivity |

(W/mK) |

300

|