Properties of recrystallized silicon carbide

Recrystallized silicon carbide (R-SiC) is a high-performance material with hardness second only to diamond, which is formed at a high temperature above 2000℃. It retains many excellent properties of SiC, such as high temperature strength, strong corrosion resistance, excellent oxidation resistance, good thermal shock resistance and so on.

● Excellent mechanical properties. Recrystallized silicon carbide has higher strength and stiffness than carbon fiber, high impact resistance, can play a good performance in extreme temperature environments, can play a better counterbalance performance in a variety of situations. In addition, it also has good flexibility and is not easily damaged by stretching and bending, which greatly improves its performance.

● High corrosion resistance. Recrystallized silicon carbide has high corrosion resistance to a variety of media, can prevent the erosion of a variety of corrosive media, can maintain its mechanical properties for a long time, has a strong adhesion, so that it has a longer service life. In addition, it also has good thermal stability, can adapt to a certain range of temperature changes, improve its application effect.

● Sintering does not shrink. Because the sintering process does not shrink, no residual stress will cause deformation or cracking of the product, and parts with complex shapes and high precision can be prepared.

|

重结晶碳化硅物理特性 Physical properties of Recrystallized Silicon Carbide |

|

|

性质 / Property |

典型数值 / Typical Value |

|

使用温度 / Working temperature (°C) |

1600°C (with oxygen), 1700°C (reducing environment) |

|

SiC含量 / SiC content |

> 99.96% |

|

自由Si含量 / Free Si content |

< 0.1% |

|

体积密度 / Bulk density |

2.60-2.70 g/cm3 |

|

气孔率 / Apparent porosity |

< 16% |

|

抗压强度 / Compression strength |

> 600 MPa |

|

常温抗弯强度 / Cold bending strength |

80-90 MPa (20°C) |

|

高温抗弯强度 Hot bending strength |

90-100 MPa (1400°C) |

|

热膨胀系数 / Thermal expansion @1500°C |

4.70 10-6/°C |

|

导热系数 / Thermal conductivity @1200°C |

23 W/m•K |

|

杨氏模量 / Elastic modulus |

240 GPa |

|

抗热震性 / Thermal shock resistance |

Extremely good |

VET Energy is the real manufacturer of customized graphite and silicon carbide products with CVD coating, can supply various customized parts for semiconductor and photovoltaic industry. Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

We continuously develop advanced processes to provide more advanced materials, and have worked out an exclusive patented technology, which can make the bonding between the coating and the substrate tighter and less prone to detachment.

|

CVD SiC薄膜基本物理性能 Basic physical properties of CVD SiC coating |

|

|

性质 / Property |

典型数值 / Typical Value |

|

晶体结构 / Crystal Structure |

FCC β phase 多晶,主要为(111)取向 |

|

密度 / Density |

3.21 g/cm³ |

|

硬度 / Hardness |

2500 维氏硬度(500g load) |

|

晶粒大小 / Grain SiZe |

2~10μm |

|

纯度 / Chemical Purity |

99.99995% |

|

热容 / Heat Capacity |

640 J·kg-1·K-1 |

|

升华温度 / Sublimation Temperature |

2700℃ |

|

抗弯强度 / Flexural Strength |

415 MPa RT 4-point |

|

杨氏模量 / Young' s Modulus |

430 Gpa 4pt bend, 1300℃ |

|

导热系数 / Thermal Conductivity |

300W·m-1·K-1 |

|

热膨胀系数 / Thermal Expansion(CTE) |

4.5×10-6K-1 |

Warmly welcome you to visit our factory, let's have further discussion!

-

CVD SiC Coated Carbon-carbon Composite CFC Boat...

-

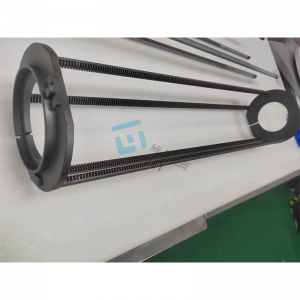

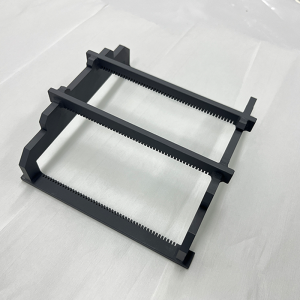

Large Size Recrystallized Silicon Carbide Wafer...

-

Custom High Purity SiC Coated Graphite Heater H...

-

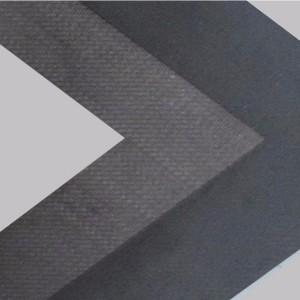

Carbon-carbon Composite Plate With SiC Coating

-

Recrystallized Silicon Carbide Wafer Boat With ...

-

Recrystallized Silicon Carbide Crystal Boat For...