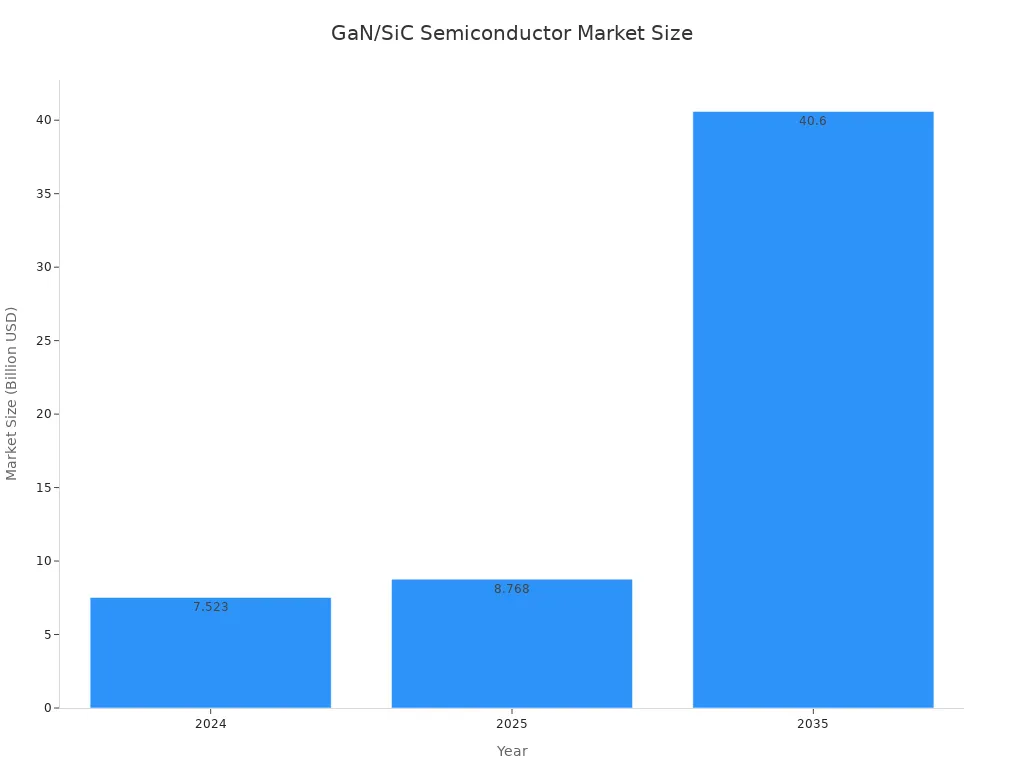

TaC coating is a high-performance ceramic layer, critical for advanced semiconductor fabrication. It is essential for SiC single crystal growth and GaN/SiC epitaxial growth processes. The GaN/SiC semiconductor market is experiencing rapid expansion. This market reached USD 7.523 billion in 2024. Experts project a 16.56% CAGR from 2025-2035.

Key Takeaways

- TaC coating is a special layer. It helps make computer chips better. It works well in very hot places.

- This coating stops bad stuff from getting into the chips. It makes the chips cleaner and stronger.

- TaC coating is better than other materials. It helps make more good chips. This makes computers and phones work better.

Understanding TaC Coating: Properties and Performance

Defining TaC Coating and Its Core Characteristics

TaC coating is a high-performance ceramic layer. Tantalum carbide (TaC) serves as its primary chemical component. Researchers investigate the Ta-C-N system, where TaC1-xNx represents the chemical composition. The base structure for experiments is fcc structured Ta-C. Stable binary structures include fcc-TaC and hex-TaN. Non-metallic vacancies are more critical than metal vacancies for stabilizing the cubic structure in Ta-C. Physical Vapor Deposition (PVD) can stabilize fcc structured Ta-C-N due to highly limited kinetics and the introduction of structural defects. A phase transition from single-phase fcc-Ta1-y-zCyNz to fcc plus hex Ta1-y-zCyNz occurs around x=0.68 in TaC1-xNx notation. Manufacturers prepare TaC coatings with four types of crystal structures on carbon/carbon composites. These structures include an acicular crystal structure, which shows better ablation resistance.

This material also exhibits impressive mechanical properties. For example, a multilayer coating with Ta(C,N) (305 nm modulation) shows a hardness of 24.5 ± 0.8 GPa and a Young’s Modulus of 263.2 ± 16.6 GPa. TaC0.71 demonstrates a hardness of 39.3 ± 1.0 GPa, with some measurements reaching 40 GPa. Its indentation modulus is 430 GPa, and the calculated Young’s Modulus for TaC is approximately 500 GPa.

| Property | Value (GPa) | Material/Condition |

|---|---|---|

| Hardness | 24.5 ± 0.8 | Multilayer coating with Ta(C,N) (305 nm modulation) |

| Young’s Modulus | 263.2 ± 16.6 | Multilayer coating with Ta(C,N) (305 nm modulation) |

| Hardness | 39.3 ± 1.0 | TaC0.71 |

| Hardness | 40 | TaC0.71 |

| Indentation Modulus | 430 | TaC0.71 |

| Young’s Modulus | ~500 | TaC (calculated) |

Exceptional High-Temperature Stability of TaC Coating

This material excels in extreme thermal environments. It remains stable at temperatures above 2000°C. Its melting point reaches an impressive 4273°C, making it one of the highest temperature-resistant compounds known. This material has a maximum operating temperature exceeding 2200°C.

TaC exhibits one of the highest melting points among known materials, measured at an impressive 4041 K. This melting point surpasses many other refractory materials, including tungsten. Laboratory tests confirm TaC’s ability to maintain structural integrity at temperatures exceeding 3000°C. TaC outperforms both ceramic and metal alloy coatings in maintaining structural integrity at these extreme temperatures. While its melting temperature (4041 K) is lower than that of HfC, TaC consistently demonstrates superior thermal resistance and chemical stability compared to traditional ceramic and metal alloy coatings.

Chemical Resistance and Ultra-High Purity of TaC Coating

TaC coatings demonstrate excellent chemical stability. They effectively resist reactions with various corrosive substances, including acids and bases. This characteristic makes them a reliable choice for demanding industrial applications. TaC coatings exhibit good chemical stability, showing resistance to acids, alkalis, salts, and organic reagents. Furthermore, they remain unaffected by molten metals, slag, and other corrosive media. TaC coatings possess strong chemical stability, enabling them to withstand numerous chemical reactions, particularly those involving acids and bases.

High purity is another critical attribute of this material. Manufacturers design TaC coatings to minimize impurities such as titanium, boron, and aluminum. Products utilizing TaC coatings exhibit minimal carbon, oxygen, nitrogen, and other impurities, contributing to cleaner crystal growth. Impurity levels in TaC coating can be as low as <5 ppm, significantly lower than SiC coating or bare graphite (which can have 260 ppm oxygen).

Thermal and Mechanical Durability of TaC Coating

This material possesses significant thermal conductivity. It measures approximately 22 W·m⁻¹·K⁻¹. In W-TaC composites, the thermal conductivity of TaC ranges from 15–35 W·m⁻¹·K⁻¹ at temperatures of 750 °C, 850 °C, and 950 °C. This high thermal conductivity aids in effectively dissipating heat during high-temperature processes. It also prevents localized overheating.

The mechanical durability of this material is also noteworthy. A NiCrBSi + Ta coating demonstrated higher fracture toughness and improved abrasive and adhesive wear resistance compared to a NiCrBSi coating without tantalum. Tantalum enhances the wear resistance of Ni-based coatings by forming fine TaC particles. For WC–6Co cemented carbides, adding 0.6 wt% TaC resulted in optimal wear resistance, reducing wear mass loss to 0.15 mg and achieving a stable coefficient of friction of approximately 0.3. A (Ta,Zr,Nb)C single-phase ceramic exhibited a fracture toughness of 2.9 MPa m1/2 at room temperature.

TaC Coating in Advanced GaN/SiC Semiconductor Processes

Enhancing SiC Single Crystal Growth with TaC Coating

TaC coating plays a crucial role in advancing SiC single crystal growth. It significantly improves crystal quality and reduces defects. For instance, it reduces micropipe defects by up to 99.7%. It also decreases threading edge dislocations by 80.5%. TaC coatings prevent the corrosion of graphite components in the harsh, high-temperature silicon vapor atmosphere. Uncoated graphite corrodes, releasing carbon particles. These particles lead to carbon encapsulation and increase defects in the growing SiC crystals. By protecting the graphite, TaC coatings ensure cleaner crystals.

The use of TaC coatings results in SiC single crystals with less carbon, oxygen, and nitrogen impurities. It minimizes edge defects and improves resistivity uniformity. Furthermore, it significantly reduces the density of micropores and etching pits. Industry studies show that TaC coating solves crystal edge defects. It also reduces the probability of polycrystalline formation at the edge of SiC crystals. Research from Eastern European University in Korea confirms that TaC-coated graphite crucibles effectively limit nitrogen incorporation. This action reduces the generation of microtubules and other defects. TaC-coated crucibles maintain almost unchanged weight and an intact appearance after long-term use. Manufacturers can recycle them multiple times. They offer a service life of up to 200 hours, improving sustainability and efficiency in the production process.

Optimizing GaN/SiC Epitaxial Growth with TaC Coating

TaC coating is equally vital for optimizing GaN/SiC epitaxial growth. This process requires an extremely stable and pure environment to achieve high-quality GaN layers on SiC substrates. The exceptional high-temperature stability of TaC ensures that process components remain structurally sound. This stability prevents material degradation even at the elevated temperatures necessary for epitaxy. Its superior thermal conductivity helps maintain precise and uniform temperature distribution across the substrate. This uniformity is critical for consistent film thickness and crystal structure.

The chemical inertness of TaC coating prevents unwanted reactions between process gases and reactor components. Such reactions could introduce impurities into the growing GaN layer. By providing a stable and non-reactive surface, TaC promotes a cleaner growth environment. This environment is essential for achieving the desired electrical properties and performance of GaN devices. The mechanical durability of TaC also contributes to the longevity of reactor parts. This durability reduces downtime and maintenance, further optimizing the overall epitaxial growth process.

Preventing Contamination and Improving Yield with TaC Coating

Preventing contamination is paramount in semiconductor manufacturing, and TaC coating excels in this area. The chemically inert nature of TaC coating prevents unwanted reactions. These reactions could introduce contaminants into the growth environment. It acts as a robust barrier against external impurities. This property ensures the production of high-purity crystals. TaC coating addresses contamination and edge defects by creating a protective layer. This layer resists material deposition and particle adhesion. It minimizes impurity introduction and reduces the likelihood of edge defects that occur with uncoated surfaces.

The ultra-high purity of TaC coatings, with impurity levels as low as <5 ppm, directly translates to cleaner SiC and GaN materials. This cleanliness reduces the incidence of various defects, including micropores and etch pits. Research from the University of Eastern Europe in Korea indicates that tantalum carbide (TaC) coated graphite crucibles effectively limit nitrogen incorporation in SiC crystals. This limitation directly reduces defects such as micropipes, thereby improving crystal quality. By minimizing contamination and defects, TaC coating significantly enhances the overall yield of high-quality semiconductor wafers. This improvement leads to more reliable and efficient device fabrication.

Why TaC Coating Outperforms Alternatives

Performance Comparison: TaC Coating vs. SiC Coating and Bare Graphite

TaC coating offers significant advantages over alternative materials like SiC coating and bare graphite in semiconductor manufacturing. Its superior properties make it the preferred choice for demanding applications. TaC coating provides enhanced performance in critical areas. These areas include high-temperature stability, chemical resistance, and purity. These benefits directly translate to improved process efficiency and product quality.

Superior Etch Resistance and Impurity Levels of TaC Coating

TaC coating demonstrates superior etch resistance. This property is crucial for components operating in harsh plasma environments. CVD TaC coatings provide excellent resistance to chemical corrosion and thermal degradation for etching tools. This resistance ensures the structural integrity of tools in plasma environments, allowing for precise etching. The coating’s anti-adhesion properties also reduce particle contamination, improving process reliability. Overall, TaC coatings minimize tool wear and enhance production efficiency, extending the lifespan of components in plasma applications. Tantalum carbide (TaC) coatings significantly extend the lifespan of components in plasma environments. They act as a protective barrier. They safeguard semiconductor components like electrodes, sensors, and chambers from degradation. This degradation is caused by corrosive gases, high temperatures, and chemical processes. TaC-coated etching chambers resist corrosive plasma environments during semiconductor fabrication. This resistance ensures equipment longevity and process integrity. This protection reduces downtime, maintenance, and replacement costs, enhancing overall productivity. Furthermore, TaC coatings boast ultra-high purity, with impurity levels often below 5 ppm. This level is significantly lower than SiC coating or bare graphite, which can contain up to 260 ppm oxygen.

Thermal Shock Resistance and Maximum Temperature Capabilities of TaC Coating

TaC coating exhibits excellent resistance to thermal shock. This property is highly beneficial for materials subjected to rapid and significant temperature changes. It ensures their reliability and performance in demanding environments. This material maintains its integrity even under extreme thermal cycling. Its maximum operating temperature also surpasses alternatives.

| Material | Max Temperature |

|---|---|

| TaC Coating | >2200°C |

| SiC Coating | <1600°C |

| Bare Graphite | ~2000°C (with degradation) |

TaC coating significantly reduces contamination and improves thermal management in semiconductor manufacturing. It offers superior performance compared to conventional materials like SiC coating and bare graphite. This advanced material is crucial for enhancing yield and reliability in GaN/SiC semiconductor processes, driving progress in the industry.

FAQ

What is the primary function of TaC coating in semiconductor manufacturing?

TaC coating serves as a high-performance ceramic layer. It protects components, reduces contamination, and manages heat effectively. This ensures optimal conditions for crystal growth.

How does TaC coating compare to SiC coating and bare graphite?

TaC coating offers superior high-temperature stability, chemical resistance, and ultra-high purity. It outperforms SiC coating and bare graphite in critical semiconductor applications.

What specific benefits does TaC coating bring to GaN/SiC processes?

TaC coating enhances SiC single crystal growth and optimizes GaN/SiC epitaxial growth. It prevents contamination, improves thermal management, and increases overall yield and reliability.

Post time: Nov-13-2025