In semiconductor and optoelectronic industries, the SiC (Silicon Carbide) carrier plays a critical role in processing ultra-thin wafers. The wafer is placed on the porous SiC carrier and securely fixed via vacuum suction, enabling seamless integration into key steps such as:

● Waxing: Applying a protective layer.

● Thinning: Reducing the wafer's thickness.

● Dewaxing: Removing the protective layer.

● Cleaning: Ensuring a pristine surface.

● Cutting (Dicing): Separating the wafer into individual dies.

SiC carriers streamline these intricate steps, contributing significantly to the efficiency and quality of your production line.

Key Features Your SiC Carrier Must Possess

When selecting a SiC carrier, certain features are paramount to ensuring optimal performance and maximizing your return on investment. We understand that technical personnel and purchasing managers prioritize specific characteristics that directly impact process efficiency and product quality.

1.Exceptional Thermal Conductivity

A superior SiC carrier boasts excellent thermal conductivity. This property is crucial for:

●Shortening Waxing and Dewaxing Times: Efficient heat transfer accelerates these thermal processes, drastically reducing overall cycle times.

●Improving Production Rate: Faster processing directly translates to a higher throughput of wafers.

●Increasing Production Efficiency: Optimized thermal management contributes to a more streamlined and productive manufacturing flow.

2.Small and Uniformly Distributed Pore Size:

The effectiveness of vacuum suction heavily relies on the carrier's pore structure. An ideal SiC carrier features:

●Small Pore Size: Prevents damage to delicate wafers and ensures even vacuum distribution.

●Well-Distributed Pores: Guarantees uniform adsorption across every localized region of the entire wafer, preventing bowing, warping, or displacement during processing.

3.Outstanding Acid and Alkali Resistance:

Given the chemical-intensive nature of wafer processing, your SiC carrier must withstand corrosive environments. High acid and alkali resistance ensures:

●Durability and Longevity: The carrier maintains its structural integrity and performance over extended periods.

●Reduced Contamination Risk: Resistance to chemical degradation minimizes the potential for impurities leaching onto the wafer.

Why Choose VET Energy for Your SiC Carriers?

At VET Energy, we are committed to providing SiC carriers that not only meet but exceed the stringent demands of the semiconductor and optoelectronic industries. Our focus on quality, customization, and reliable delivery sets us apart.

●Various Sizes and Specifications: Our SiC carriers can be customized to perfectly match your specific wafer dimensions and equipment requirements.

●Smooth Surface Finish: Meticulously polished to prevent any scratching or damage to delicate wafers, safeguarding your valuable products.

●Fast Delivery: We pride ourselves on efficient production and logistics, ensuring your orders are delivered promptly to keep your operations running smoothly.

|

CVD SiC Basic physical properties of CVD SiC coating |

|

|

Property |

Typical Value |

|

Crystal Structure |

FCC β phase polycrystalline, mainly (111) orientation |

|

Density |

3.21 g/cm³ |

|

Hardness |

2500 Vickers hardness (500g load) |

|

Grain SiZe |

2~10μm |

|

Chemical Purity |

99.99995% |

|

Heat Capacity |

640 J·kg-1·K-1 |

|

Sublimation Temperature |

2700℃ |

|

Flexural Strength |

415 MPa RT 4-point |

|

Young' s Modulus |

430 Gpa 4pt bend, 1300℃ |

|

Thermal Conductivity |

300W·m-1·K-1 |

|

Thermal Expansion(CTE) |

4.5×10-6K-1 |

VET Energy is a professional manufacturer focusing on the R&D and production of high-end advanced materials such as graphite, silicon carbide, quartz, as well as the material treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc. The products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc..

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

VET Energy advantages includes:

• Own factory and professional laboratory;

• Industry-leading purity levels and quality;

• Competive price & Fast delivery time;

• Multiple industry partnerships worldwide;

We welcome you to vist our factory and laboratory at any time!

-

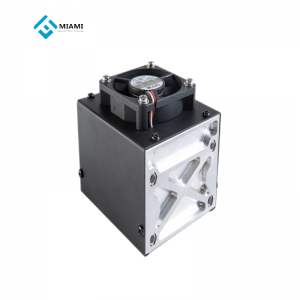

Customized Fuel Cell Energy Storage Mobile Powe...

-

Drone Hydrogen Fuel Cell High-quality hydrogen ...

-

Graphite nuts and bolts for vacuum furnace indu...

-

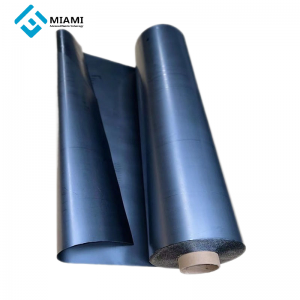

Graphite paper carbon outlet flexible graphite ...

-

Graphite/Carbon Screw, Graphite Bolt for Contin...

-

Rechargeable Renewable 15v Pemfc stack 200w hyd...