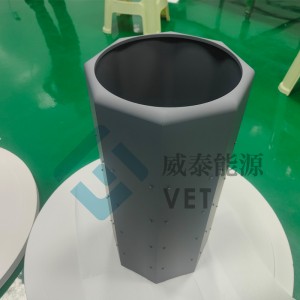

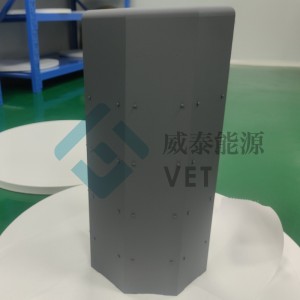

Barrel susceptor is a core component in semiconductor epitaxial growth processes such as MOCVD, MBE, CVD. It is mainly used to carry wafers in high-temperature reaction chambers and provide a uniform and stable thermal field environment to ensure precise deposition of epitaxial layers (such as GaN, SiC, etc.). Its core function is to achieve high uniformity of wafer surface temperature through precise thermal field control, thereby ensuring the thickness, doping concentration, and crystal structure uniformity of epitaxial thin films.

We use our patented technology to make the barrel susceptor with extremely high purity, good coating uniformity and an excellent service life, as well as high chemical resistance and thermal stability properties.

VET Energy use high purity graphite with CVD-SiC coating to enhance the chemical stability:

1. High purity graphite material

High thermal conductivity: the thermal conductivity of graphite is three times that of silicon, which can quickly transfer heat from the heating source to the wafer and shorten the heating time.

Mechanical strength: Isostatic pressure graphite density ≥ 1.85 g/cm ³, capable of withstanding high temperatures above 1200 ℃ without deformation.

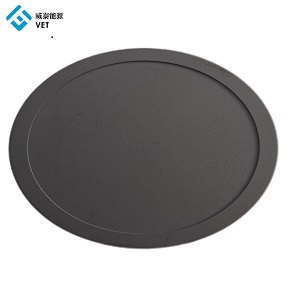

2. CVD SiC coating

A β - SiC layer is formed on the surface of graphite by chemical vapor deposition (CVD), with a purity of ≥ 99.99995%, the uniformity error of coating thickness is less than±5%, and the surface roughness is less than Ra0.5um.

3. Performance improvement:

Corrosion resistance: can withstand high corrosive gases such as Cl2, HCl,etc, can extend the lifespan of GaN epitaxy by three times in the NH3 environment.

Thermal stability: The coefficient of thermal expansion (4.5 × 10-6/℃) matches graphite to avoid coating cracking caused by temperature fluctuations.

Hardness and Wear Resistance: The Vickers hardness reaches 28 GPa, which is 10 times higher than graphite and can reduce the risk of wafer scratches.

|

CVD SiC薄膜基本物理性能 Basic physical properties of CVD SiC coating |

|

|

性质 / Property |

典型数值 / Typical Value |

|

晶体结构 / Crystal Structure |

FCC β phase 多晶,主要为(111)取向 |

|

密度 / Density |

3.21 g/cm³ |

|

硬度 / Hardness |

2500 维氏硬度(500g load) |

|

晶粒大小 / Grain SiZe |

2~10μm |

|

纯度 / Chemical Purity |

99.99995% |

|

热容 / Heat Capacity |

640 J·kg-1·K-1 |

|

升华温度 / Sublimation Temperature |

2700℃ |

|

抗弯强度 / Flexural Strength |

415 MPa RT 4-point |

|

杨氏模量 / Young' s Modulus |

430 Gpa 4pt bend, 1300℃ |

|

导热系数 / Thermal Conductivity |

300W·m-1·K-1 |

|

热膨胀系数 / Thermal Expansion(CTE) |

4.5×10-6K-1 |

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the development and production of high-end advanced materials, the materials and technology including graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., these products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc.

Our technical team comes from top domestic research institutions, and have developed multiple patented technologies to ensure product performance and quality, can also provide customers with professional material solutions.