How to use graphite rotor correctly

1. Preheating before use: the graphite rotor shall be preheated at about 100mm above the liquid level for 5min ~ 10min before immersion in aluminum liquid to avoid the impact of Quench on raw materials; The rotor must be filled with gas before immersion in liquid; The air supply can be stopped only after the rotor raises the liquid level, so as to avoid the blockage of the air hole of the rotor nozzle.

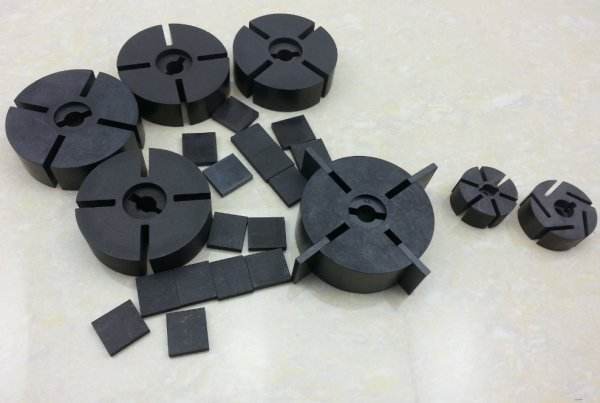

2. Stable transmission system: the graphite rotor and the transmission system are connected through the connecting rod (pipe). The deformation of the connecting rod under the effect of high temperature for a long time, or the loosening of relevant parts of the transmission equipment, will affect the neutrality and operation stability of the rotor, and it is easy to break or bump the graphite rotor.

3. Rotor immersion depth: the graphite rotor is immersed in the aluminum melt at a reasonable depth, so that the reinforcing sleeve is exposed to the aluminum liquid level by about 80mm and immersed below the liquid level by about 60mm, which can effectively increase the anti-oxidation loss and scouring wear time of the rotor.

4. Block air: fill nitrogen or argon into the purification box to ensure positive pressure in the box and block external air to avoid oxidation of graphite rotor.

5. Pure argon or nitrogen: if the leakage of pipeline and connector parts causes the impure argon or nitrogen gas into aluminum melt, the upper part of the rotor will be seriously oxidized, and even several rotor air jet holes at the lower part will be oxidized, which will greatly shorten the service life of the rotor.

Post time: Dec-23-2021