The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for Professional China China Sic Boat Carry Silicon Wafers Into The High Temperature Diffusion Coating Furnace Tube, Our ultimate goal is always to rank as a top brand and also to lead as a pioneer in our field. We are sure our productive experience in tool creation will get customer’s trust, Wish to co-operate and co-create an even better long term with you!

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for China Carry Silicon Wafers, Polycrystallie Silicon Wafer, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner to suit your needs!

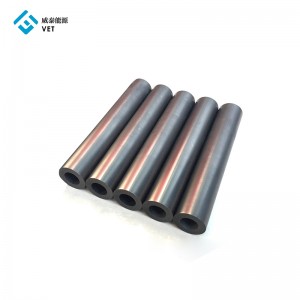

Product Description

Silicon carbide Wafer Boat are widely used as a wafer holder in high temperature diffusion process.

Advantages:

High temperature resistance: normal use at 1800 ℃

High thermal conductivity: equivalent to graphite material

High hardness: hardness second only to diamond, boron nitride

Corrosion resistance: strong acid and alkali have no corrosion to it, the corrosion resistance is better than tungsten carbide and alumina

Light weight: low density, close to aluminum

No deformation: low coefficient of thermal expansion

Thermal shock resistance: it can withstand sharp temperature changes, resist thermal shock, and has stable performance

Physical Properties Of SiC

| Property | Value | Method |

| Density | 3.21 g/cc | Sink-float and dimension |

| Specific heat | 0.66 J/g °K | Pulsed laser flash |

| Flexural strength | 450 MPa560 MPa | 4 point bend, RT4 point bend, 1300° |

| Fracture toughness | 2.94 MPa m1/2 | Microindentation |

| Hardness | 2800 | Vicker’s, 500g load |

| Elastic ModulusYoung’s Modulus | 450 GPa430 GPa | 4 pt bend, RT4 pt bend, 1300 °C |

| Grain size | 2 – 10 µm | SEM |

Thermal Properties Of SiC

| Thermal Conductivity | 250 W/m °K | Laser flash method, RT |

| Thermal Expansion (CTE) | 4.5 x 10-6 °K | Room temp to 950 °C, silica dilatometer |

-

OEM Supply Flexible Graphite Carbon Graphite Sh...

-

Bottom price Hot Sale Bipolar Graphite Electrod...

-

Catalyst Converter Scrap Fuel Cell Components M...

-

ODM Manufacturer China 75ml Digestion Tube Use ...

-

Top Grade 300ml Clean Energy Pure Water Hydroge...

-

New Delivery for Graphite Flow Field Graphite B...