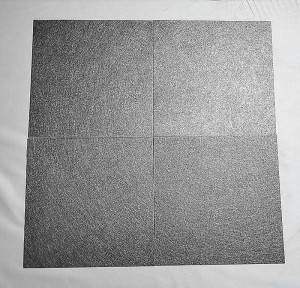

I-6 Intshi ye-Semi Insulating SiC Wafer evela kwi-VET Energy sisisombululo esiphezulu samandla aphezulu kunye nezicelo eziphezulu ze-frequency, ezinikezela nge-conductivity ephezulu ye-thermal kunye nokufakelwa kombane. Ezi ziphako zi-semi-insulating zibalulekile kuphuhliso lwezixhobo ezifana ne-RF amplifiers, iiswitshi zamandla, kunye nezinye izinto ezinombane ophezulu. Amandla e-VET aqinisekisa umgangatho kunye nokusebenza okungaguqukiyo, okwenza ezi ziqwenga zilungele uluhlu olubanzi lweenkqubo zokwenziwa kwe-semiconductor.

Ukongeza kwiipropathi zabo ezibalaseleyo zokugquma, ezi ziqwenga ze-SiC ziyahambelana nezixhobo ezahlukeneyo ezibandakanya iSi Wafer, iSiC Substrate, i-SOI Wafer, iSiN Substrate, kunye ne-Epi Wafer, izenza ziguquguquke kwiintlobo ezahlukeneyo zenkqubo yokwenziwa. Ngaphezu koko, izixhobo eziphucukileyo ezifana ne-Gallium Oxide Ga2O3 kunye ne-AlN Wafer zingasetyenziswa ngokudityaniswa nezi ziphaluka ze-SiC, zibonelela nokuguquguquka okukhulu ngakumbi kwizixhobo zombane ezinamandla aphezulu. Iiwafers ziyilelwe ukuhlanganiswa okungenamthungo kunye neenkqubo zokuphatha ezisemgangathweni ezifana neenkqubo zeCassette, eziqinisekisa ukusetyenziswa ngokulula kwimimiselo yokuvelisa ubuninzi.

I-VET Energy inikezela ngepotfoliyo ebanzi yee-semiconductor substrates, kuquka i-Si Wafer, i-SiC Substrate, i-SOI Wafer, i-SiN Substrate, i-Epi Wafer, i-Gallium Oxide Ga2O3, kunye ne-AlN Wafer. Umgca wethu weemveliso ezahlukeneyo ubonelela kwiimfuno zezicelo ezahlukeneyo ze-elektroniki, ukusuka kumbane we-elektroniki ukuya kwi-RF kunye ne-optoelectronics.

I-6 intshi ye-semi-insulating ye-SiC wafer ibonelela ngeenzuzo ezininzi:

Amandla ombane aphezulu wokuqhekeka: I-bandgap ebanzi ye-SiC yenza amandla ombane aphezulu, okuvumela izixhobo zamandla ezixineneyo nezisebenzayo.

Ukusebenza kobushushu obuphezulu: I-SiC ye-thermal conductivity egqwesileyo yenza ukusebenza kumaqondo obushushu aphezulu, ukuphucula ukuthembeka kwesixhobo.

Ukumelana okuphantsi: Izixhobo ze-SiC zibonisa ukuxhathisa okuphantsi, ukunciphisa ilahleko yamandla kunye nokuphucula ukusebenza kakuhle kwamandla.

I-VET Amandla ibonelela ngeewafers zeSiC ezinokwenziwa ngokwezifiso ukuze zihlangabezane neemfuno zakho ezithile, kubandakanya ubukhulu obahlukeneyo, amanqanaba e-doping, kunye nokugqitywa komphezulu. Iqela lethu leengcali libonelela ngenkxaso yobugcisa kunye nenkonzo emva kokuthengisa ukuqinisekisa impumelelo yakho.

IINGCACISO ZOKUPHAZAMISEKA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Into | 8-intshi | 6-Intshi | 4-intshi | ||

| nP | n-Pm | n-Nd | SI | SI | |

| TTV(GBIR) | ≤6um | ≤6um | |||

| I-Bow(GF3YFCD)-Ixabiso elipheleleyo | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| I-LTV(SBIR)-10mmx10mm | <2μm | ||||

| Wafer Edge | Beveling | ||||

UPHANDO GQIBELA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Into | 8-intshi | 6-Intshi | 4-intshi | ||

| nP | n-Pm | n-Nd | SI | SI | |

| Umphezulu Gqiba | Icala eliphindwe kabini le-Optical Polish, iSi- Face CMP | ||||

| Ubunzima boMphezulu | (10um x 10um) Si-FaceRa≤0.2nm | (5umx5um) Si-Face Ra≤0.2nm | |||

| IiChips zoMda | Akukho okuvunyelweyo (ubude nobubanzi≥0.5mm) | ||||

| Iindenti | Akukho Ivumelekileyo | ||||

| Imikrwelo(Si-Face) | Ubuninzi.≤5,Yongezeleka | Ubuninzi.≤5,Yongezeleka | Ubuninzi.≤5,Yongezeleka | ||

| Iintanda | Akukho Ivumelekileyo | ||||

| Ukungabandakanywa kuMda | 3mm | ||||

-

Umvelisi wepakethi yebhetri yomsinga we-vanadium...

-

Iseli yePEM yosasazo lwerhasi umaleko weplatinam-egqunywe ti ...

-

I-Silicon Carbide Coated Graphite Substrate ye-S...

-

Isitaki seSeli ye-Hydrogen yeFuel yaMandla eChaneke kakhulu H...

-

Amanzi apholise i-injini ye-hydrogen ye-fuel cell ngaphandle...

-

Ubungakanani oMkhulu obuphinde buphinde bufakwe kwiSilicon Carbide Wafer...