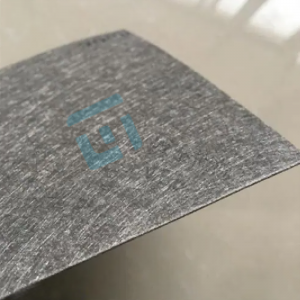

SiC Wafer Cassette and Carrier

Silicon carbide wafer cassette is primarily for supporting and transporting the wafers in high-temperature thermal processes of semiconductor wafers such as diffusion, oxidation, and annealing. Its performance directly affects wafer product quality and production efficiency.

The structural designs of silicon carbide wafer boat:

Typically has a slotted or comb-like structure;

Multiple slots for placing and separating wafers;

Designed to consider gas flow distribution, ensuring uniform heating and cooling;

Suitable for vertical furnace and horizontal furnace;

Designed for different sizes such 3inch, 4inch, 6inch, 8inch, 12inch wafers.

VET Energy's silicon carbide wafer boats are crafted using advanced sintering technology and are specifically designed to meet the stringent process carrier requirements of advanced semiconductor manufacturing. Their superior technical advantages are primarily reflected in the following aspects:

1. Ultimate Purity and Ultra-Low Contamination

Using ultra-high-purity raw materials, we ensure the product has an extremely low metal ion content (less than 1 ppm for Na, K, Fe, and Ca). Minimal precipitation at high temperatures effectively prevents wafer contamination, ensuring high chip yield and reliability, making them an ideal choice for those striving for process perfection.

2. Excellent Thermal Performance and Stability

Our SiC wafer boat possess extremely high thermal conductivity and excellent thermal shock resistance. They can withstand rapid temperature fluctuations from room temperature to 1600℃ without cracking or deformation, ensuring process repeatability and consistency, significantly reducing unplanned downtime due to carrier issues.

3.Extraordinary Corrosion Resistance and Mechanical Strength

High hardness and strong wear resistance, along with exceptional resistance to acidic and alkaline environments, far surpasses quartz and graphite. Its exceptional mechanical strength effectively prevents particle generation during frequent automated handling, significantly extending its service life and reducing overall operating costs.

4. Precision Design and Excellent Consistency

Leveraging advanced molding and processing technologies, we ensure that each wafer boat possesses precise geometric dimensions and excellent surface accuracy, ensuring uniform wafer spacing and stable airflow.

The Cleaning and Maintenance of SiC wafer boat:

Requires regular cleaning to remove potential deposits;

Uses specialized cleaning solutions and methods to avoid damage;

|

重结晶碳化硅物理特性 Physical properties of Recrystallized Silicon Carbide |

|

|

性质 / Property |

典型数值 / Typical Value |

|

使用温度 / Working temperature (°C) |

1600°C (with oxygen), 1700°C (reducing environment) |

|

SiC含量 / SiC content |

> 99.96% |

|

自由Si含量 / Free Si content |

< 0.1% |

|

体积密度 / Bulk density |

2.60-2.70 g/cm3 |

|

气孔率 / Apparent porosity |

< 16% |

|

抗压强度 / Compression strength |

> 600 MPa |

|

常温抗弯强度 / Cold bending strength |

80-90 MPa (20°C) |

|

高温抗弯强度 Hot bending strength |

90-100 MPa (1400°C) |

|

热膨胀系数 / Thermal expansion @1500°C |

4.70 10-6/°C |

|

导热系数 / Thermal conductivity @1200°C |

23 W/m•K |

|

杨氏模量 / Elastic modulus |

240 GPa |

|

抗热震性 / Thermal shock resistance |

Extremely good |

VET Energy is a professional manufacturer focusing on the R&D and production of high-end advanced materials such as graphite, silicon carbide, quartz, as well as the material treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc. The products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc..

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

VET Energy advantages includes:

• Own factory and professional laboratory;

• Industry-leading purity levels and quality;

• Competive price & Fast delivery time;

• Multiple industry partnerships worldwide;

We welcome you to vist our factory and laboratory at any time!