VET Energy's independently developed CVD tantalum carbide (TaC) coating wafer susceptor is designed for harsh working conditions such as semiconductor manufacturing, LED epitaxial wafer growth (MOCVD), crystal growth furnace, high-temperature vacuum heat treatment, etc. Through chemical vapor deposition (CVD) technology, a dense and uniform tantalum carbide coating is formed on the surface of the graphite substrate, giving the tray ultra-high temperature stability (>3000℃), resistance to molten metal corrosion, thermal shock resistance and low pollution characteristics, significantly extending the service life.

Our technical advantages:

1. Ultra-high temperature stability.

3880°C Melting Point: Tantalum carbide coating can operate continuously and stably above 2500°C, far exceeding the 1200-1400°C decomposition temperature of conventional silicon carbide (SiC) coatings.

Thermal shock resistance: The thermal expansion coefficient of the coating matches that of the graphite substrate (6.6×10 -6 /K), and can withstand rapid temperature rise and fall cycles with a temperature difference of more than 1000°C to avoid cracking or falling off.

High temperature mechanical properties: The coating hardness reaches 2000 HK (Vickers hardness) and the elastic modulus is 537 GPa, and it still maintains excellent structural strength at high temperatures.

2. Extremely corrosion-resistant to ensure process purity

Excellent resistance: It has excellent resistance to corrosive gases such as H₂, NH₃, SiH₄, HCl and molten metals (e.g. Si, Ga), completely isolating the graphite substrate from the reactive environment and avoiding carbon contamination.

Low impurity migration: ultra-high purity, effectively inhibit the migration of nitrogen, oxygen and other impurities to the crystal or epitaxial layer, reducing the defect rate of microtubes by more than 50%.

3. Nano-level precision to improve process consistency

Coating uniformity: thickness tolerance≤±5%, surface flatness reaches nanometer level, ensuring high consistency of wafer or crystal growth parameters, thermal uniformity error<1%.

Dimensional accuracy: supports ±0.05mm tolerance customization, adapts to 4-inch to 12-inch wafers, and meets the needs of high-precision equipment interfaces.

4. Long-lasting and durable, reducing overall costs

Bonding strength: The bonding strength between the coating and the graphite substrate is ≥5 MPa, resistant to erosion and wear, and the service life is extended by more than 3 times.

Machine Compatibility

Suitable for mainstream epitaxial and crystal growth equipment such as CVD, MOCVD, ALD, LPE, etc., covering SiC crystal growth (PVT method), GaN epitaxy, AlN substrate preparation and other scenarios.

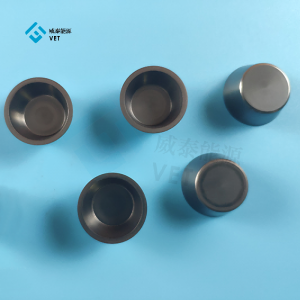

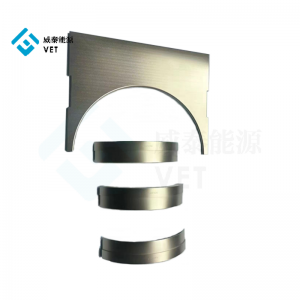

We provide a variety of susceptor shapes such as flat, concave, convex, etc. The thickness (5-50mm) and positioning hole layout can be adjusted according to the cavity structure to achieve seamless Compatibility with the equipment.

Main Applications:

SiC crystal growth: In the PVT method, the coating can optimize the thermal field distribution, reduce edge defects, and increase the effective growth area of the crystal to more than 95%.

GaN epitaxy: In the MOCVD process, the susceptor thermal uniformity error is <1%, and the consistency of epitaxial layer thickness reaches ±2%.

AlN substrate preparation: In the high temperature (>2000°C) amination reaction, the TaC coating can completely isolate the graphite substrate, avoid carbon contamination, and improve the purity of the AlN crystal.

|

碳化钽涂层物理特性物理特性 Physical properties of TaC coating |

|

|

密度 / Density |

14.3 (g/cm³) |

|

比辐射率 / Specific emissivity |

0.3 |

|

热膨胀系数 / Thermal expansion coefficient |

6.3 10-6/K |

|

努氏硬度 / Hardness (HK) |

2000 HK |

|

电阻 / Resistance |

1×10-5 Ohm*cm |

|

热稳定性 / Thermal stability |

<2500℃ |

|

石墨尺寸变化 / Graphite size changes |

-10~-20um |

|

涂层厚度 / Coating thickness |

≥30um typical value (35um±10um) |

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the development and production of high-end advanced materials, the materials and technology including graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., these products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc.

Our technical team comes from top domestic research institutions, and have developed multiple patented technologies to ensure product performance and quality, can also provide customers with professional material solutions.