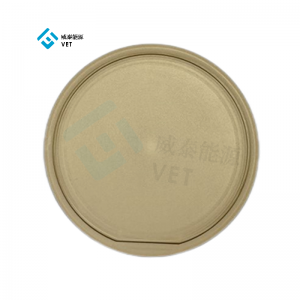

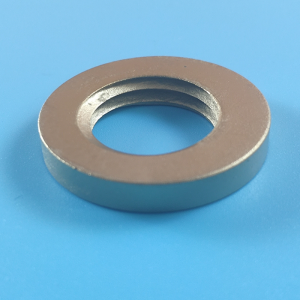

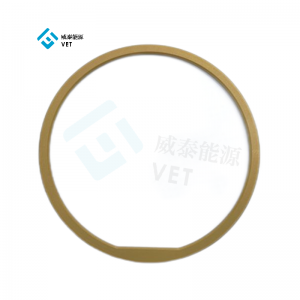

VET Energy focuses on the R&D and production of high-performance CVD tantalum carbide (TaC) coated graphite rings, and is committed to providing core consumable material solutions for semiconductor, photovoltaic and high-temperature industries. Our independently developed chemical vapor deposition (CVD) technology forms a dense and uniform tantalum carbide coating on the surface of the graphite substrate through precision processes, significantly improving the product's high temperature resistance (>3000℃), corrosion resistance and thermal shock resistance, extending the service life by more than 3 times, and reducing customers comprehensive costs.

Our technical advantages:

1. High temperature oxidation resistance

In an air atmosphere of 1200℃, the oxidation weight gain rate is ≤0.05mg/cm²/h, which is more than 3 times the oxidation resistance life of ordinary graphite, and is suitable for high-frequency heating-cooling cycle conditions.

2. Resistance to molten silicon/metal corrosion

TaC coating is extremely inert to metals such as liquid silicon (1600℃), molten aluminum/copper, etc., avoiding structural failure of traditional guide rings due to metal penetration, especially suitable for power semiconductors and third-generation semiconductor manufacturing.

3. Ultra-low particle contamination

The CVD process achieves a coating density of >99.5% and a surface roughness of Ra≤0.2μm, reducing the risk of particle shedding from the source and meeting the stringent cleanliness requirements of 12-inch wafer manufacturin.

4. Precise size control

Adopting CNC precision machining, the size tolerance of graphite substrate is ±0.01mm, and the overall deformation after coating is <±5μm, which is suitable for installation in high-precision equipment chambers.

|

碳化钽涂层物理特性物理特性 Physical properties of TaC coating |

|

|

密度 / Density |

14.3 (g/cm³) |

|

比辐射率 / Specific emissivity |

0.3 |

|

热膨胀系数 / Thermal expansion coefficient |

6.3 10-6/K |

|

努氏硬度 / Hardness (HK) |

2000 HK |

|

电阻 / Resistance |

1×10-5 Ohm*cm |

|

热稳定性 / Thermal stability |

<2500℃ |

|

石墨尺寸变化 / Graphite size changes |

-10~-20um |

|

涂层厚度 / Coating thickness |

≥30um typical value (35um±10um) |

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the development and production of high-end advanced materials, the materials and technology including graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., these products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc.

Our technical team comes from top domestic research institutions, and have developed multiple patented technologies to ensure product performance and quality, can also provide customers with professional material solutions.