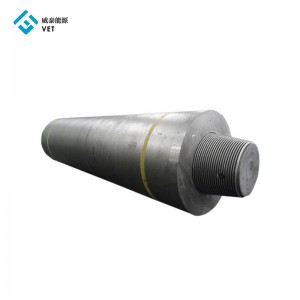

Epitaxial Epi Graphite Barrel Susceptor

Epitaxial Epi Graphite Barrel SusceptorHe kākoʻo kūikawā i hoʻolālā ʻia a me ka mea hoʻomehana i hoʻohana ʻia e paʻa a wela i nā substrates semiconductor i ka wā o ka hana ʻana e like me nā kaʻina hana Deposition a Epitaxy.

ʻO ke ʻano o kona ʻano he cylindrical a i ʻole ke ʻano barela liʻiliʻi.

ʻO nā hana nui o ka epitaxial barrel susceptor:

1. Ka Wafer Carrier a me ka Mana wela

Hoʻolālā ʻia ka ʻili o ka susceptor me nā ʻeke wafer he nui (e like me ka hoʻonohonoho hexagonal a octagonal paha), hiki ke kākoʻo i nā wafers 6-15 i ka manawa like. ʻO ka conductivity thermal kiʻekiʻe o ka graphite maʻemaʻe kiʻekiʻe (120-150W / mK) e hōʻoia i ka hoʻoili wela wikiwiki, i hui pū ʻia me ka hana rotation (5-20 RPM), ka hopena i kahi haʻahaʻa haʻahaʻa o ka ʻili o<± 1 ℃ a me ka epitaxial layer mānoanoa like ʻole o <1%.

2. Optimization o reactant kinoea holo kuhikuhi

Hiki i ka microstructure o ka ʻili susceptor ke wāwahi i ka hopena o ka papa palena, e ʻae ana i ka hoʻohele like ʻana o nā kinoea hopena (e like me SiH4, NH3) a me ka hoʻomaikaʻi ʻana i ke kūlike o ka helu deposition.

3. Anti pollution a me ka pale anti-corrosion

Hiki ke hoʻoheheʻe a hoʻokuʻu i nā mea ʻino metala (e like me Fe, Ni) i nā wela kiʻekiʻe, ʻoiai he 100μm mānoanoa CVD SiC uhi hiki ke hana i kahi pale paʻa e hoʻopau i ka graphite volatilization, e hopena i ka helu defect wafer o <0.1 defects/cm ².

Nā noi:

- Hoʻohana mua ʻia no ka ulu ʻana o ka epitaxial silicon

-Pono no ka epitaxy o nā mea semiconductor ʻē aʻe e like me GaAs, InP, etc.

Hoʻohana ʻo VET Energy i ka graphite maʻemaʻe kiʻekiʻe me ka uhi CVD-SiC e hoʻomaikaʻi i ke kūpaʻa kemika:

1. High maemae graphite mea

ʻO ka conductivity thermal kiʻekiʻe: ʻo ka conductivity thermal o ka graphite he ʻekolu manawa o ka silicon, hiki ke hoʻololi koke i ka wela mai ke kumu hoʻomehana i ka wafer a hoʻopōkole i ka manawa hoʻomehana.

Mechanical ikaika: Isostatic pressure graphite density ≥ 1.85 g/cm ³, hiki ke kū i nā wela kiʻekiʻe ma luna o 1200 ℃ me ka ʻole deformation.

2. CVD SiC uhi

Hoʻokumu ʻia kahi papa β - SiC ma ka ʻili o ka graphite e ka hoʻoheheʻe ʻana i ka mahu (CVD), me ka maʻemaʻe o ≥ 99.99995%, ʻo ka hapa like ʻole o ka mānoanoa o ka uhi ʻana ma lalo o ± 5%, a ʻoi aku ka liʻiliʻi o ka roughness ma mua o Ra0.5um.

3. Hoʻomaikaʻi i ka hana:

ʻO ke kūpaʻa ʻino: hiki ke kū i nā kinoea corrosive kiʻekiʻe e like me Cl2, HCl, a me nā mea ʻē aʻe, hiki ke hoʻolōʻihi i ke ola o GaN epitaxy i ʻekolu mau manawa ma ke kaiapuni NH3.

ʻO ke kūpaʻa wela: ʻO ke koena o ka hoʻonui wela (4.5 × 10-6/℃) pili i ka graphite e pale aku i ka haki ʻana o ka uhi ma muli o ka loli ʻana o ka mahana.

ʻO ka paʻakikī a me ka pale ʻana: ʻO ka paʻakikī Vickers hiki i ka 28 GPa, ʻo ia ka 10 mau manawa kiʻekiʻe ma mua o ka graphite a hiki ke hōʻemi i ka pilikia o ka wafer scratches.

| CVD SiC薄膜基本物理性能 Nā waiwai kino kumu o CVD SiCka uhi ʻana | |

| 性质 / Waiwai | 典型数值 / Waiwai maʻamau |

| 晶体结构 / Hoʻomoe Crystal | Māhele FCC β多晶,主要为(111)取向 |

| 密度 / Paʻa | 3.21 g/cm³ |

| 硬度 / Oolea | 2500 维氏硬度(500g load) |

| 晶粒大小 / ʻAiʻa palaoa | 2~10μm |

| 纯度 / Maemae Kemika | 99.99995% |

| 热容 / Hikina Wela | 640 J·kg-1·K-1 |

| 升华温度 / Kaumaha Sublimation | 2700 ℃ |

| 抗弯强度 / Ka Ikaika Pilikia | 415 MPa RT 4-point |

| 杨氏模量 / 'Ōpio's Modulus | 430 Gpa 4pt piko, 1300 ℃ |

| 导热系数 / ThermalʻO ka hoʻokō | 300W·m-1·K-1 |

| 热膨胀系数 / Hoʻonui wela (CTE) | 4.5×10-6K-1 |

ʻO Ningbo VET Energy Technology Co., Ltd kahi ʻoihana ʻenehana kiʻekiʻe e kālele ana i ka hoʻomohala ʻana a me ka hana ʻana i nā mea kiʻekiʻe kiʻekiʻe, nā mea a me nā ʻenehana me ka graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc.

Hele mai kā mākou hui ʻenehana mai nā keʻena noiʻi kūloko kiʻekiʻe, a ua hoʻomohala i nā ʻenehana patented he nui e hōʻoia i ka hana a me ka maikaʻi o ka huahana, hiki nō hoʻi ke hāʻawi i nā mea kūʻai aku i nā ʻoihana ʻoihana.

-

Pemfc wahie cell 24v 1000w hydrogen wahie cell pa...

-

ʻO ke koʻokoʻo graphite kiʻekiʻe no ka hana ʻana / moʻi ...

-

Hoʻolālā kūikawā no ka Dia.200mm ~ 600mm Graphit maikaʻi loa ...

-

Drone Hydrogen Fuel Cell 220w Generator Hydroge...

-

ʻO ka wela kiʻekiʻe maʻamau a ʻaʻahu i ka sili kūpaʻa ...

-

1000w wahie pahu waihona 24v Pemfc ahu hydrogen ...