Epitaxial Epi Graphite Barrel Susceptor

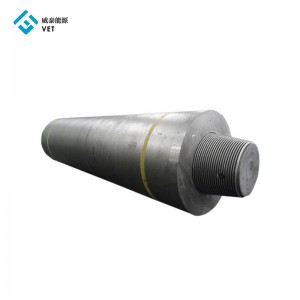

Epitaxial Epi Graphite Barrel Susceptorbụ ngwa nkwado na kpo oku a haziri ahazi nke a na-eji na-ejide ma na-ekpo ọkụ semiconductor substrates n'oge mmepụta ihe dị ka Deposition ma ọ bụ Epitaxy usoro.

Ọdịdị ya na-agụnye ụdị cylindrical ma ọ bụ ntakịrị barel, n'elu nwere ọtụtụ akpa ma ọ bụ ikpo okwu maka idobe wafers, nwere ike ịbụ ihe siri ike ma ọ bụ oghere, dabere na usoro kpo oku.

Ọrụ bụ isi nke susceptor barrel epitaxial:

1. Onye na-ebu Wafer na njikwa okpomọkụ

Ejiri ọtụtụ akpa wafer (dị ka nhazi hexagonal ma ọ bụ octagonal), nke nwere ike ịkwado 6-15 wafers n'otu oge. The elu thermal conductivity nke elu-ọcha graphite (120-150W / mK) ana achi achi ngwa ngwa okpomọkụ nyefe, jikọtara na adiana ọrụ (5-20 RPM), dapụtara na a wafer elu okpomọkụ deviation nke <± 1 ℃ na epitaxial oyi akwa ọkpụrụkpụ uniformity nke <1%.

2. Optimization nke reactant gas eruba direction

Microstructure nke elu susceptor nwere ike mebie mmetụta oyi akwa oke, na-enye ohere maka nkesa gasị mmeghachi omume otu (dị ka SiH4, NH3) ma melite nkwụsi ike nke ọnụego nkwụnye ego.

3. Mgbochi mmetọ na mgbochi corrosion nchebe

Ihe ndị na-ese onyinyo na-adịkarị mfe ire ere ma hapụkwa ihe ndị na-adịghị ọcha ígwè (dị ka Fe, Ni) na okpomọkụ dị elu, ebe mkpuchi CVD SiC 100μm nwere ike ịmepụta ihe mgbochi siri ike iji gbochie graphite volatilization, na-ebute nkwụsịtụ ntụpọ nke <0.1 ntụpọ / cm ².

Ngwa:

-A na-ejikarị eme ihe maka uto silicon epitaxial

-Ọdabara maka epitaxy nke ihe ndị ọzọ semiconductor dị ka GaAs, InP, wdg.

VET Energy na-eji graphite dị ọcha na mkpuchi CVD-SiC kwalite nkwụsi ike kemịkalụ:

1. Akwa graphite dị ọcha

Igwe ọkụ ọkụ dị elu: conductivity thermal conductivity nke graphite bụ okpukpu atọ nke silicon, nke nwere ike ịnyefe ọkụ ngwa ngwa site na isi iyi ọkụ na wafer ma belata oge kpo oku.

Mechanical ike: Isostatic mgbali graphite njupụta ≥ 1.85 g / cm ³, ike iguzogide elu okpomọkụ n'elu 1200 ℃ na-enweghị deformation.

2. CVD SiC mkpuchi

A β-SiC oyi akwa kpụrụ n'elu graphite site chemical vapor deposition (CVD), na ịdị ọcha nke ≥ 99.99995%, uniformity njehie nke mkpuchi ọkpụrụkpụ bụ ihe na-erughị ± 5%, na elu roughness bụ ihe na-erughị Ra0.5um.

3. Mmelite arụmọrụ:

Nguzogide corrosion: nwere ike iguzogide ikuku na-emebi emebi dị ka Cl2, HCl, wdg, nwere ike ịgbatị ndụ GaN epitaxy ugboro atọ na gburugburu NH3.

Nkwụsi ike nke okpomọkụ: ọnụọgụ nke mgbasawanye okpomọkụ (4.5 × 10-6 / ℃) dakọtara graphite iji zere mkpuchi mkpuchi nke mgbanwe okpomọkụ kpatara.

Isi ike na iyi Nguzogide: Ike siri ike nke Vickers ruru 28GPa, nke dị okpukpu iri karịa graphite ma nwee ike ibelata ihe ize ndụ nke nchapu wafer.

| CVD SiC薄膜基本物理性能 Njirimara anụ ahụ bụ isi nke CVD SiCmkpuchi | |

| 性质 / Ihe onwunwe | 典型数值 / Uru a na-ahụkarị |

| 晶体结构 / Crystal Structure | FCC β oge多晶,主要为(111) 取向 |

| 密度 / Njupụta | 3.21g/cm³ |

| 硬度 / Isi ike | 2500 维氏硬度 (ibu 500g) |

| 晶粒大小 / ọka SiZe | 2 ~ 10μm |

| 纯度 / Chemical ịdị ọcha | 99.99995% |

| 热容 / Okpomọkụ Ike | 640 nk-1· K-1 |

| 升华温度 / Sublimation okpomọkụ | 2700 ℃ |

| 抗弯强度 / Ike Flexural | 415 MPa RT 4-isi |

| 杨氏模量 Modul nke Young's | 430 Gpa 4pt ekwe, 1300 ℃ |

| 导热系数 / ThermalOmume omume | 300W·m-1· K-1 |

| 热膨胀系数 Mgbasawanye okpomọkụ (CTE) | 4.5 × 10-6K-1 |

Ningbo VET Energy Technology Co., Ltd bụ a elu-tech enterprise na-elekwasị anya na mmepe na mmepụta nke elu-ọgwụgwụ elu ihe, ihe na nkà na ụzụ gụnyere graphite, silicon carbide, ceramics, elu ọgwụgwọ dị ka SiC mkpuchi, TaC mkpuchi, glassy carbon mkpuchi, pyrolytic carbon mkpuchi, wdg, ndị a ngwaahịa na-ọtụtụ-eji na photovoltaic, semiconductor, ọhụrụ ume, metallurgy, metallurgy.

Anyị ọrụ otu si n'elu ụlọ nnyocha ụlọ ọrụ, na mepụtara multiple patented teknụzụ iji hụ na ngwaahịa arụmọrụ na àgwà, nwekwara ike inye ndị ahịa na ọkachamara ihe ngwọta.

-

Pemfc Fuel Cell 24v 1000w Hydrogen Fuel Cell Pa...

-

High mma graphite mkpanaka maka nhazi / ọla ...

-

Pụrụ iche iche maka Best Dia.200mm ~ 600mm Graphit...

-

Drone Hydrogen Fuel Cell 220w Generator Hydroge ...

-

Omenala elu okpomọkụ na eyi sili na-eguzogide ọgwụ ...

-

1000w Mmanụ ụgbọala Stack 24v Pemfc Stack Hydrogen ...