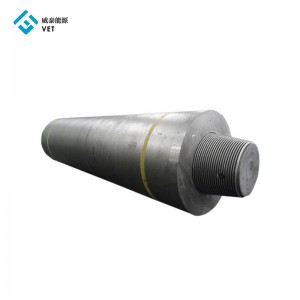

Epitaxial Epi Graphite Barrel Susceptor

Epitaxial Epi Graphite Barrel Susceptorke sesebelisoa se khethehileng sa tšehetso le ho futhumatsa se sebelisetsoang ho tšoara le ho futhumatsa li-semiconductor substrates nakong ea mekhoa ea tlhahiso e kang Deposition kapa Epitaxy process.

Sebopeho sa eona se kenyelletsa cylindrical kapa sebopeho sa moqomo hanyane, bokaholimo bo na le lipokothong tse ngata kapa sethala sa ho beha li-wafers, e ka ba moralo o tiileng kapa o se nang letho, ho latela mokhoa oa ho futhumatsa.

Mesebetsi ea mantlha ea epitaxial barrel susceptor:

1. Wafer Carrier le Taolo ea Mocheso

Sebaka sa susceptor se entsoe ka lipokotho tse ngata tsa wafer (joalo ka tlhophiso ea hexagonal kapa octagonal), e ka tšehetsang li-wafers tse 6-15 ka nako e le 'ngoe. Mocheso o phahameng oa mocheso oa graphite o hloekileng (120-150W / mK) o tiisa mocheso o potlakileng oa mocheso, o kopantsoeng le mosebetsi oa ho potoloha (5-20 RPM), o fella ka ho kheloha ha mocheso holim'a mocheso oa <± 1 ℃ le epitaxial layer botenya bo lekanang le <1%.

2. Ntlafatso ea tataiso ea phallo ea khase e reactant

The microstructure ea susceptor surface e ka senya phello ea moeli oa moeli, e lumella ho aroloa ka mokhoa o ts'oanang oa likhase tse arabelang (tse kang SiH4, NH3) le ho ntlafatsa ho lumellana ha tekanyo ea deposition.

3. Khahlanong le tšilafalo le tšireletso e khahlanong le kutu

Li-substrates tsa graphite li na le tšekamelo ea ho bola le ho lokolla litšila tsa tšepe (tse kang Fe, Ni) ka mocheso o phahameng, ha 100μm e teteaneng ea CVD SiC coating e ka etsa mokoallo o teteaneng oa ho hatella graphite volatilization, e leng se bakang sekhahla sa bokooa ba <0.1 defects/cm².

Lisebelisoa:

-E sebelisoa haholo bakeng sa kholo ea silicon epitaxial

-E boetse e sebetsa bakeng sa epitaxy ea lisebelisoa tse ling tsa semiconductor tse kang GaAs, InP, joalo-joalo.

VET Energy e sebelisa graphite e hloekileng haholo e nang le CVD-SiC coating ho matlafatsa botsitso ba lik'hemik'hale:

1. Boitsebiso bo phahameng ba graphite bo hloekileng

Thermal conductivity: thermal conductivity of graphite ke makhetlo a mararo a silicon, e ka fetisang mocheso ka potlako ho tloha mohloling oa mocheso ho ea ho sephaphatha le ho khutsufatsa nako ea ho futhumatsa.

Matla a mochine: Isostatic pressure graphite density ≥ 1.85 g/cm ³, e khonang ho mamella mocheso o phahameng ka holimo ho 1200 ℃ ntle le ho senyeha.

2. Ho roala ha CVD SiC

A β - SiC layer e thehoa holim'a graphite ka lik'hemik'hale tsa mouoane oa lik'hemik'hale (CVD), ka bohloeki ba ≥ 99.99995%, phoso e ts'oanang ea botenya ba ho roala e ka tlaase ho ± 5%, 'me bokaholimo bo ka tlaase ho Ra0.5um.

3. Ntlafatso ea ts'ebetso:

Corrosion resistance: e ka mamella likhase tse senyang tse ngata joalo ka Cl2, HCl, joalo-joalo, e ka lelefatsa bophelo ba GaN epitaxy ka makhetlo a mararo tikolohong ea NH3.

Thermal botsitso: Coefficient ea ho atolosoa ha mocheso (4.5 × 10-6 / ℃) e lumellana le graphite ho qoba ho phatloha ho bakoang ke ho fetoha ha mocheso.

Ho thatafala le ho Rua Resistance: The Vickers hardness fihla 28 GPa, e leng makhetlo a 10 ho feta graphite 'me e ka fokotsa kotsi ea li-wafer scratches.

| CVD SiC薄膜基本物理性能 Lintho tsa motheo tsa 'mele tsa CVD SiCho roala | |

| 性质 / Thepa | 典型数值 / Boleng bo Tlwaelehileng |

| 晶体结构 / Sebopeho sa Crystal | FCC mohato oa β多晶,主要為(111)取向 |

| 密度 / Ho teteana | 3.21 g/cm³ |

| 硬度 / Ho thatafala | 2500 维氏硬度 (500g mojaro) |

| 晶粒大小 / Mabele SiZe | 2 ~ 10μm |

| 纯度 / Bohloeki ba lik'hemik'hale | 99.99995% |

| 热容 / Bokhoni ba mocheso | 640 J·kg-1·K-1 |

| 升华温度 / Sublimation Mocheso | 2700 ℃ |

| 抗弯强度 / Flexural Matla | 415 MPa RT 4-ntlha |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt kobeha, 1300 ℃ |

| 导热系数 / ThermalBoikhantšo | 300Wm-1·K-1 |

| 热膨胀系数 / Katoloso ea Mocheso(CTE) | 4.5×10-6K-1 |

Ningbo VET Energy Technology Co., Ltd ke khoebo ea theknoloji e phahameng e shebaneng le nts'etsopele le tlhahiso ea lisebelisoa tse tsoetseng pele tsa maemo a holimo, lisebelisoa le theknoloji e kenyelletsang graphite, silicon carbide, ceramics, kalafo ea holim'a metsi joalo ka SiC coating, TaC coating, khalase ea khabone, pyrolytic carbon coating, jj.

Sehlopha sa rona sa botekgeniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, 'me se thehile mahlale a mangata a nang le tokelo ea ho netefatsa ts'ebetso ea sehlahisoa le boleng, hape se ka fa bareki litharollo tsa thepa ea litsebi.

-

Pemfc Fuel Cell 24v 1000w Hydrogen Fuel Cell Pa...

-

Molamu oa boleng bo holimo oa graphite bakeng sa ho sebetsa / lehakoe ...

-

Moralo o Khethehileng oa Dia.200mm~600mm Graphit...

-

Drone Hydrogen Fuel Cell 220w Jenereithara ea Hydroge...

-

Mocheso o phahameng oa tloaelo 'me u apare silila e hanyetsanang le...

-

1000w Fuel Cell Stack 24v Pemfc Stack Hydrogen ...