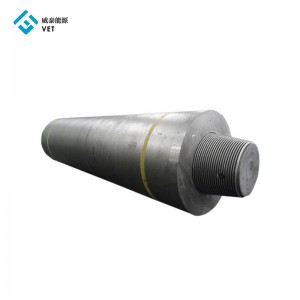

Epitaxial Epi Graphite Barrel Susceptor

Epitaxial Epi Graphite Barrel Susceptorndeye yakanyatsogadzirirwa rutsigiro uye yekudziya mudziyo unoshandiswa kubata uye kupisa semiconductor substrates panguva yekugadzira maitiro seDeposition kana Epitaxy maitiro.

Chimiro chayo chinosanganisira anowanzo cylindrical kana zvishoma mbiya-yakaita, pamusoro inoratidzira akawanda homwe kana mapuratifomu ekuisa mawaferi, anogona kuve akasimba kana maburi dhizaini, zvichienderana nenzira yekudziya.

Iwo makuru mabasa epitaxial barrel susceptor:

1. Wafer Carrier uye Temperature Control

Iyo susceptor yepamusoro yakagadzirwa iine akawanda wafer homwe (senge hexagonal kana octagonal kurongeka), iyo inogona kutsigira 6-15 wafers panguva imwe chete. Iyo yakanyanya kupisa conductivity ye-high-purity graphite (120-150W/mK) inovimbisa kukurumidza kupisa kupisa, kusanganiswa nekutenderera basa (5-20 RPM), zvichikonzera kutsauka kwekushisa kwepamusoro kwe<± 1 ℃ uye epitaxial layer ukobvu kufanana kwe<1%.

2. Optimization of reactant gas flow direction

Iyo microstructure ye susceptor surface inogona kutyora muganho dhizaini mhedzisiro, ichibvumira kugovera kwakafanana kwemagasi ekuita (senge SiH4, NH3) nekuvandudza kuenderana kweyero deposition.

3. Anti kusvibiswa uye anti-corrosion kudzivirira

Graphite substrates inowanzoora uye kuburitsa tsvina yesimbi (yakadai seFe, Ni) pakupisa kwakanyanya, ukuwo 100μm gobvu CVD SiC coating inogona kuumba dense chipingamupinyi kudzvanyirira graphite volatilization, zvichikonzera kuwanda kwewafer defect ye<0.1 defects/cm².

Applications:

-Inonyanya kushandiswa silicon epitaxial kukura

-Inoshandawo kune epitaxy yezvimwe semiconductor zvinhu seGaAs, InP, nezvimwe.

VET Energy inoshandisa yakakwira kuchena graphite neCVD-SiC coating kusimudzira kugadzikana kwemakemikari:

1. High kuchena graphite zvinhu

High thermal conductivity: thermal conductivity ye graphite yakapetwa katatu iyo yesilicon, iyo inogona kukurumidza kutamisa kupisa kubva kune inopisa sosi kusvika kune wafer uye kupfupisa nguva yekupisa.

Mechanical simba: Isostatic pressure graphite density ≥ 1.85 g/cm ³, inokwanisa kushingirira tembiricha yepamusoro pamusoro pe1200 ℃ pasina deformation.

2. CVD SiC kupfeka

A β - SiC layer inoumbwa pamusoro pegraphite nekemikari vapor deposition (CVD), ine kuchena kwe ≥ 99.99995%, kukanganisa kwakafanana kwekuputira ukobvu kunodarika ± 5%, uye kushata kwepamusoro kuri pasi peRa0.5um.

3. Kuvandudzwa kwekuita:

Corrosion resistance: inogona kumirisana nemagasi anoodza zvakanyanya seCl2, HCl, nezvimwewo, inogona kuwedzera hupenyu hweGaN epitaxy katatu munzvimbo yeNH3.

Thermal kugadzikana: The coefficient of thermal expansion (4.5 × 10-6 / ℃) inofananidzwa negraphite kuti irege kuvhara kuputika kunokonzerwa nekushanduka kwekushisa.

Kuoma uye Kupfeka Kuramba: Kuoma kweVickers kunosvika 28 GPa, iyo yakapetwa ka10 kupfuura graphite uye inogona kuderedza njodzi yezvimedu zvewafer.

| CVD SiC薄膜基本物理性能 Basic zvemuviri zvimiro zveCVD SiCcoating | |

| 性质 / Property | 典型数值 / Typical Value |

| 晶体结构 / Crystal Mamiriro | FCC β chikamu多晶,主要為(111)取向 |

| 密度 / Density | 3.21 g/cm³ |

| 硬度 / Kuoma | 2500 维氏硬度 (500g mutoro) |

| 晶粒大小 / Zviyo SiZe | 2~10μm |

| 纯度 / Kemikari Kuchena | 99.99995% |

| 热容 / Kupisa Kugona | 640 J·kg-1·K-1 |

| 升华温度 / Sublimation Temperature | 2700 ℃ |

| 抗弯强度 / Flexural Simba | 415 MPa RT 4-poindi |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt bend, 1300 ℃ |

| 导热系数 / ThermalConductivity | 300Wm-1·K-1 |

| 热膨胀系数 / Kuwedzera Kupisa (CTE) | 4.5 × 10-6K-1 |

Ningbo VET Energy Technology Co., Ltd ibhizimusi repamusoro-soro rinotarisa mukusimudzira nekugadzirwa kwezvinhu zvepamusoro-soro, zvekushandisa uye tekinoroji zvinosanganisira graphite, silicon carbide, ceramics, kurapwa kwepamusoro seSiC coating, TaC coating, girazi kabhoni coating, pyrolytic kabhoni coating, nezvimwewo, zvigadzirwa izvi zvinoshandiswa zvakanyanya muphotovoltaic, semiconductor itsva, semicondurgy.

Chikwata chedu chehunyanzvi chinobva kumasangano epamusoro ekutsvagisa edzimba, uye akagadzira akawanda ematekinoroji matekinoroji ekuona kuita kwechigadzirwa uye mhando, anogona zvakare kupa vatengi mhinduro dzehunyanzvi.

-

Pemfc Fuel Cell 24v 1000w Hydrogen Fuel Cell Pa...

-

Yepamusoro mhando graphite tsvimbo yekugadzirisa / jewel ...

-

Special Design for Best Dia.200mm~600mm Graphit...

-

Drone Hydrogen Fuel Cell 220w Jenareta Hydroge...

-

Tsika yakakwira tembiricha uye kupfeka inodzivirira sili...

-

1000w Fuel Cell Stack 24v Pemfc Stack Hydrogen ...