Advanced Porous Ceramic Vacuum Chuck

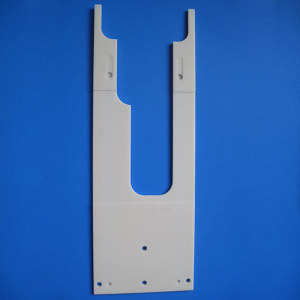

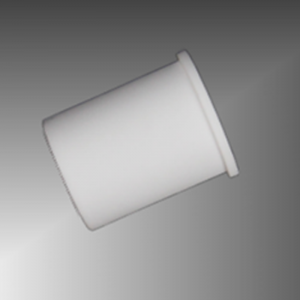

Porous Ceramic Vacuum Chuckdandamali ne mai ɗaukar kaya wanda ke amfani da ƙa'idar tallan injin don gyara kayan aiki. Bangaren vacuum chuck wanda ke watsa vacuum farantin yumbu mai ƙyalli ce. An haɗa farantin yumbu mai ƙuri'a a cikin rami mai nutsewa na tushe, kuma an haɗa gefensa kuma an rufe shi da tushe. Tushen an yi shi da madaidaicin yumbu ko kayan ƙarfe. Ta hanyar haɗa tushe na ƙarfe ko yumbu tare da yumbu mai ƙyalli na musamman, ƙirar madaidaicin hanyar iska ta ciki tana ba da damar santsi da kwanciyar hankali na workpiece zuwa kofin tsotsawa lokacin da aka fuskanci mummunan matsa lamba.

Saboda daɗaɗɗen pores a cikin yumbu mara kyau, ana iya manne da saman kayan aikin zuwa kofin tsotsa ba tare da wasu abubuwa masu banƙyama ba kamar su ɓarna ko ɓarna wanda ya haifar da mummunan matsa lamba.

Halayen Porous Ceramic Vacuum Chuck:

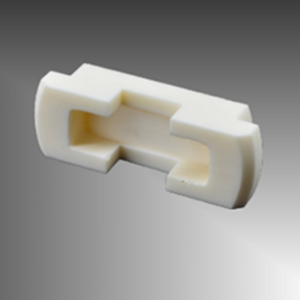

① Tsari mai yawa & uniform: Yana tsayayya da siliki foda / tallan tarkace, mai sauƙin tsaftacewa.

② Ƙarfin ƙarfi & juriya: Babu nakasawa yayin niƙa, yana rage girman guntuwa / rarrabuwa.

③ Dogon rayuwa: Kyakkyawan riƙe siffar saman, dogon zagayowar sutura tare da ƙarancin cirewa.

④ Babban rufi: Yana kawar da wutar lantarki.

⑤ Mai sake amfani da su & mai sauƙin sutura: Babu fashewa/chipping yayin sake farfadowa, sake amfani da yawa zai yiwu.

⑥ Ba kura ba & barga: Cikakken sintered, babu fitar da barbashi.

⑦ Haske mai nauyi: Tsarin ƙura yana rage nauyi sosai.

⑧ Juriya na sinadarai: Ana iya daidaita shi don yanayin lalata ta hanyar sarrafa kayan / tsari.

Ceramic Vacuum Chuck VS Traditional Metal Suction Cup:

Yumbun injin yumbu a cikin filin semiconductor

Yumbun injin yumbu suna aiki azaman matsawa da ɗaukar kayan aiki a samar da wafer semiconductor. Sun ƙunshi babban lebur da daidaito, tsari mai yawa kuma iri ɗaya, ƙarfi mai ƙarfi, kyakyawan iska mai ƙarfi, ƙarfin adsorption iri ɗaya, da sutura mai sauƙi. Waɗannan halayen sun sa su dace da matakai a masana'antar wafer semiconductor kamar su bakin ciki, slicing, niƙa, tsaftacewa, da sarrafawa. Suna magance ƙalubalen yadda ya kamata kamar buga wafer, rugujewar kwakwalwan kwamfuta, da gurɓataccen barbashi, samun babban ingancin sarrafawa don wafers na semiconductor a aikace-aikace masu amfani.

Takardar bayanai na Kayan yumbu

| Abu | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | SilikiNtsiri | AluminumNtsiri |

| Launi | fari | rawaya mai haske | fari | baki | baki | launin toka |

| Yawan yawa (g/cm3) | 3.7g/cm 3 | 3.9g/cm 3 | 6.02g/cm 3 | 3.2g/cm 3 | 3.25g/cm 3 | 3.2g/cm 3 |

| Shakar Ruwa | 0% | 0% | 0% | 0% | 0% | 0% |

| Hardness (HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Ƙarfin Ƙarfi (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Ƙarfin Ƙarfi (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Modulus Na Matasa Na Ƙarfafawa | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310-350GPa |

| Rabon Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Ƙarfin Dielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Juyin Juriya (25 ℃) | > 1014Ω · cm | > 1014Ω · cm | > 1014Ω · cm | > 105Ω · cm | > 1014Ω · cm | > 1014Ω · cm |

VET Energy ne mai sana'a manufacturer mayar da hankali a kan R & D da kuma samar da high-karshen ci-gaba kayan kamar graphite, silicon carbide, ma'adini, kazalika da kayan magani kamar SiC shafi, TaC shafi, glassy carbon shafi, pyrolytic carbon shafi, da dai sauransu A kayayyakin da ake amfani da ko'ina a photovoltaic, semiconductor, sabon makamashi, karfe, da dai sauransu.

Ƙungiyarmu ta fasaha ta fito ne daga manyan cibiyoyin bincike na gida, za su iya samar da ƙarin ƙwararrun kayan aiki don ku.

Abubuwan amfani da makamashi na VET sun haɗa da:

• Ma'aikata da kuma ƙwararrun dakin gwaje-gwaje;

• matakan tsabta masu jagorancin masana'antu da inganci;

• Farashin farashi & Lokacin bayarwa da sauri;

• Haɗin gwiwar masana'antu da yawa a duniya;

Muna maraba da ku zuwa vist mu masana'anta da dakin gwaje-gwaje a kowane lokaci!