Iterambere ryiza rya Ceramic Vacuum Chuck

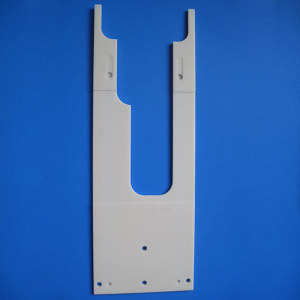

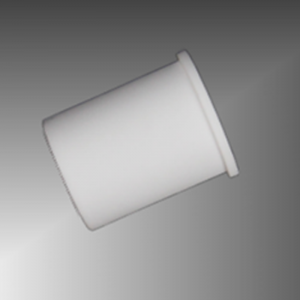

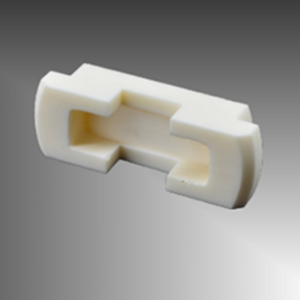

Vacuum Chuckni umutwaro utwara umutwaro ukoresha ihame rya vacuum adsorption kugirango ukosore ibihangano. Igice cya vacuum chuck cyanduza vacuum ni isahani yuzuye ceramic. Isahani ya ceramique isobekeranye mu mwobo urohama, kandi impande zose zirahambiriwe kandi zifunze hamwe na base. Urufatiro rukozwe mubikoresho byiza bya ceramic cyangwa ibyuma. Muguhuza icyuma cyangwa ceramique hamwe na ceramic idasanzwe, igishushanyo mbonera cyimbere yimbere ituma habaho guhuza neza kandi bihamye igihangano cyakazi mugikombe cyokunywa vacuum mugihe gitewe nigitutu kibi.

Bitewe na pore nziza cyane mubutaka bwubutaka, ubuso bwakazi burashobora gufatanwa nigikombe cyokunywa vacuum nta mpamvu mbi nko gushushanya cyangwa amenyo yatewe numuvuduko mubi.

Ibiranga Vacuum Chuck:

① Imiterere yuzuye & Imiterere imwe: Irwanya ifu ya silicon / gusya imyanda adsorption, byoroshye kuyisukura.

Imbaraga nyinshi & kwambara birwanya: Nta guhindagurika mugihe cyo gusya, bigabanya inkombe / gucamo ibice.

Ubuzima burebure: Kugumana imiterere yubuso buhebuje, kuzenguruka birebire hamwe no gukuramo bike.

Ins Gukwirakwiza cyane: Kurandura amashanyarazi ahamye.

Kongera gukoreshwa & byoroshye kwambara: Nta guturika / gukata mugihe cyo kongera kugaruka, gukoresha inshuro nyinshi birashoboka.

⑥ Kudakunguta & gutuza: Byacumuye byuzuye, nta byuka bihumanya.

Umucyo woroshye: Imiterere nini igabanya ibiro cyane.

Resistance Kurwanya imiti: Guhindura ibidukikije byangirika ukoresheje ibikoresho / kugenzura ibintu.

Ceramic Vacuum Chuck VS Igikombe Gisanzwe Cyicyuma:

Ceramic vacuum chuck mumashanyarazi ya semiconductor

Ceramic vacuum chucks ikora nko gufatira no gutwara ibikoresho mubikorwa bya semiconductor wafer. Biranga uburinganire buringaniye hamwe nuburinganire, imiterere yuzuye kandi imwe, imbaraga nyinshi, uburyo bwiza bwo guhumeka neza, imbaraga za adsorption, hamwe no kwambara byoroshye. Ibiranga bituma bikwiranye nibikorwa mubikorwa bya semiconductor wafer nko kunanura, gukata, gusya, gusukura, no gukora. Bakemura neza ibibazo nko gucapa wafer, kumeneka kwa electrostatike ya chipi, no kwanduza uduce, kugera kubintu byiza cyane byo gutunganya ibyuka bya semiconductor mubikorwa bifatika.

Urupapuro rwamakuru rwibikoresho bya Ceramic

| Ingingo | 95% Alumina | 99% Alumina | Zirconiya | Carbide | SiliconNitride | AluminiumNitride |

| Ibara | cyera | Umuhondo werurutse | cyera | umukara | umukara | imvi |

| Ubucucike (g / cm3) | 3.7g / cm3 | 3.9g / cm3 | 6.02g / cm3 | 3.2g / cm3 | 3.25g / cm3 | 3.2g / cm3 |

| Gukuramo Amazi | 0% | 0% | 0% | 0% | 0% | 0% |

| Gukomera (HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Imbaraga zoroshye (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Imbaraga Zikomeretsa (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Umusore Modulus Ya Elastique | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Ikigereranyo cya Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Amashanyarazi | 20W / m ° C. | 32W / m ° C. | 3W / m ° C. | 50W / m ° C. | 25W / m ° C. | 150W / m ° C. |

| Imbaraga za Dielectric | 14KV / mm | 14KV / mm | 14KV / mm | 14KV / mm | 14KV / mm | 14KV / mm |

| Ingano yo Kurwanya (25 ℃) | > 1014Ω · cm | > 1014Ω · cm | > 1014Ω · cm | > 105Ω · cm | > 1014Ω · cm | > 1014Ω · cm |

VET Energy ni uruganda rukora umwuga rwibanda kuri R&D no gukora ibikoresho byo mu rwego rwo hejuru nka grafite, karubide ya silicon, quartz, ndetse no kuvura ibikoresho nka SiC coating, TaC coating, carbone carbone, pirolitike ya karubone, n'ibindi.

Itsinda ryacu rya tekinike rituruka mubigo byubushakashatsi bwo murugo, birashobora kuguha ibisubizo byumwuga kubwawe.

Inyungu zingufu za VET zirimo:

• Uruganda bwite na laboratoire yabigize umwuga;

• Inganda ziyobora inganda nubuziranenge;

• Igiciro cyo guhatanira & Igihe cyo gutanga vuba;

• Ubufatanye butandukanye bwinganda kwisi yose;

Turakwakiriye neza kugirango ubone uruganda na laboratoire igihe icyo aricyo cyose!