Advanced Porous Ceramic Vacuum Chuck

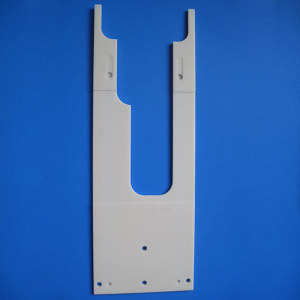

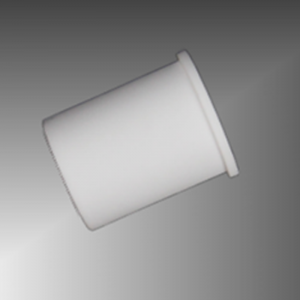

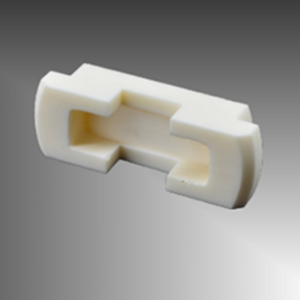

Porous Ceramic Vacuum Chuckliqonga elithwele umthwalo elisebenzisa umgaqo we-vacuum adsorption ukulungisa izixhobo zokusebenza. Inxalenye ye-vacuum chuck ehambisa i-vacuum yipleyiti ye-ceramic eneporous. I-plate ye-ceramic ye-porous ihlanganiswe kumngxuma wokutshona wesiseko, kwaye i-periphery yayo iboshwe kwaye itywinwe ngesiseko. Isiseko senziwe nge-ceramic echanekileyo okanye izinto zetsimbi. Ngokudibanisa isiseko sesinyithi okanye i-ceramic kunye ne-ceramic ekhethekileyo ye-porous, uyilo lwendlela yomoya echanekileyo yangaphakathi ivumela ukunamathela okugudileyo kunye nokuzinza kwendawo yokusebenza kwikomityi yokufunxa i-vacuum xa iphantsi koxinzelelo olubi.

Ngenxa yemingxuma ecolekileyo kakhulu kwiiseramics ezinabileyo, umphezulu wesixhobo sokusebenza unokuncamathela kwikomityi yokufunxa ivacuum ngaphandle kwezinto ezimbi ezifana nemikrwelo okanye izibonda ezibangelwa luxinzelelo olubi.

Iimpawu zePorous Ceramic Vacuum Chuck:

① Ubume obuxineneyo kunye nobufanayo: Ixhathisa umgubo wesilicon / i-adsorption yokugaya inkunkuma, kulula ukuyicoca.

② Amandla aphezulu kunye nokumelana nokunxiba: Akukho deformation ngexesha lokugaya, kunciphisa i-edge chipping / ukwahlula.

③ Ubomi obude: Ugcino lwemilo yomphezulu ogqwesileyo, umjikelo omde wokunxiba kunye nokususwa okuncinci.

④ Ukugquma okuphezulu: Ukuphelisa umbane ongatshintshiyo.

⑤ Iyasebenziseka kwakhona kwaye kulula ukunxiba: Akukho kuqhekeka / ukuqhekeka ngexesha lokuphinda kufakwe umphezulu, ukusetyenziswa kwakhona okuninzi kunokwenzeka.

⑥ Aluthuli kwaye luzinzile: I-sintered ngokupheleleyo, akukho kukhutshwa kwamasuntswana.

⑦ I-Lightweight: Isakhiwo se-porous sinciphisa kakhulu ubunzima.

⑧ Ukuxhathisa kwiMichiza: Ukwenziwa ngokwezifiso kwindawo ezonakalisayo ngokulawulwa kwezinto / inkqubo.

ICeramic Vacuum iChuck VS indebe yesiNtu yokufunxa isinyithi:

I-Ceramic vacuum chuck kwintsimi ye-semiconductor

Ii-chucks ze-Ceramic vacuum zisebenza njenge-clamping kunye nokuthwala izixhobo kwimveliso ye-wafer ye-semiconductor. Zibonisa ukuphakama okuphezulu kunye nokuhambelana, isakhiwo esixineneyo kunye nesifanayo, amandla aphezulu, ukunyanzeliswa komoya okulungileyo, amandla afanayo adsorption, kunye nokunxiba lula. Ezi mpawu zibenza bafaneleke kwiinkqubo zokwenziwa kwe-wafer ye-semiconductor njengokucolwa, ukusika, ukucola, ukucoca, kunye nokuphatha. Bajongana ngempumelelo nemiceli mngeni efana nokuprintwa kwe-wafer, ukonakaliswa kwe-electrostatic yeechips, kunye nokungcoliseka kwamasuntswana, ukuzuza umgangatho ophezulu wokusetyenzwa kwee-wafers ze-semiconductor kwizicelo ezisebenzayo.

Iphepha leDatha leMathiriyeli yeCeramic

| Into | 95% iAlumina | 99% iAlumina | Zirconia | I-silicon carbide | IsiliconNhamba | AluminiyamNhamba |

| Umbala | mhlophe | Mthubi okhanyayo | mhlophe | mnyama | mnyama | ngwevu |

| Ubuninzi (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Ukufunxwa kwamanzi | 0% | 0% | 0% | 0% | 0% | 0% |

| Ukuqina(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Amandla eFlexural (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Amandla oxinzelelo (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Imodyuli eNcinci ye-Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Umlinganiselo wePoisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| I-Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Amandla eDielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ukuxhathisa uMqulu (25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

I-VET Energy ngumvelisi oqeqeshiweyo ogxile kwi-R & D kunye nokuveliswa kwezinto eziphezulu eziphezulu ezifana negraphite, i-silicon carbide, i-quartz, kunye nonyango lwezinto eziphathekayo ezifana ne-SiC yokubeka, i-TaC yokugqoka, i-glassy carbon coating, i-pyrolytic ye-carbon coating, njl. Iimveliso zisetyenziswa ngokubanzi kwi-photovoltaic, semiconductor, amandla amatsha, isinyithi, njl.

Iqela lethu lobuchwephesha livela kumaziko aphezulu ophando lwasekhaya, linokubonelela ngezisombululo zemathiriyeli yobuchwephesha.

Izibonelelo zamandla e-VET ziquka:

• Umzi-mveliso ongowakho kunye nelebhu yobungcali;

• Amanqanaba okucoceka ahamba phambili kushishino kunye nomgangatho;

• Ixabiso elikhuphisanayo kunye nexesha lokuhanjiswa ngokukhawuleza;

• Intsebenziswano yamashishini amaninzi kwihlabathi jikelele;

Siyakwamkela ukuba ujonge umzi-mveliso wethu kunye nelabhoratri nangaliphi na ixesha!

-

Semiconductor Alumina Ceramic Plate

-

Isikhephe seQuartz esicocekileyo soKusetyenzwa kweWafer

-

Isiko lobushushu obuphezulu kunye nokumelana nomhlwa...

-

Ubunyulu obuphezulu be-alumina ceramic Ingalo yeMechanical

-

Iiseramikhi zealumina zeSemiconductor Insulating Cover

-

Semiconductor Alumina iiseramics Insulating Insulating