To ti ni ilọsiwaju seramiki Vacuum Chuck

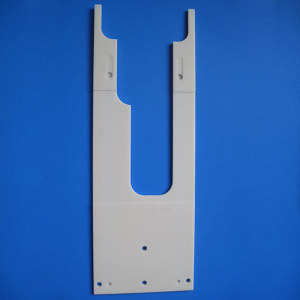

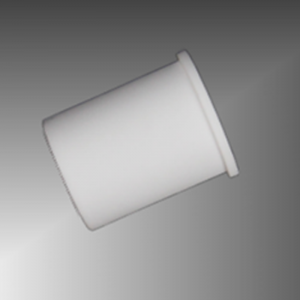

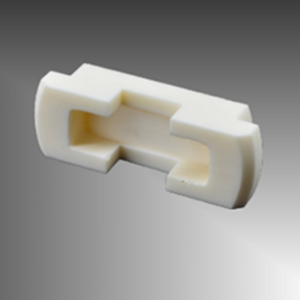

La kọja seramiki Vacuum Chuckni a fifuye-ara Syeed ti o nlo awọn opo ti igbale adsorption lati fix workpieces. Apakan igbale chuck ti o ndari igbale jẹ awo seramiki la kọja. Awo seramiki ti o ni la kọja ni a pejọ sinu iho ti o rì ti ipilẹ, ati ẹba rẹ ti so pọ ati tii pẹlu ipilẹ. Ipilẹ jẹ ti seramiki konge tabi awọn ohun elo irin. Nipa apapọ irin tabi ipilẹ seramiki pẹlu seramiki la kọja pataki kan, apẹrẹ ti ọna atẹgun inu inu ngbanilaaye fun didan ati isunmọ iduroṣinṣin ti iṣẹ ṣiṣe si ago igbale igbale nigbati o tẹri si titẹ odi.

Nitori awọn pores ti o dara pupọ julọ ni awọn ohun elo amọ la kọja, dada ti workpiece le ni ifaramọ si ago igbale igbale laisi eyikeyi awọn ifosiwewe ikolu gẹgẹbi awọn idọti tabi awọn ehín ti o fa nipasẹ titẹ odi.

Awọn abuda ti Seramiki Vacuum Chuck La kọja:

① Ipon & ilana aṣọ: Koju ohun alumọni lulú / ipolowo idoti lilọ, rọrun lati sọ di mimọ.

② Agbara giga & resistance resistance: Ko si abuku lakoko lilọ, dinku chipping eti / Fragmentation.

③ Igbesi aye gigun: Idaduro apẹrẹ dada ti o dara julọ, ọmọ wiwu gigun pẹlu yiyọkuro kekere.

④ Idabobo giga: Yọ ina ina aimi kuro.

⑤ Tunṣe & rọrun lati imura: Ko si wo inu / chipping lakoko isọdọtun, ilotunlo pupọ ṣee ṣe.

⑥ Ti kii ṣe eruku & iduroṣinṣin: Sintetiki ni kikun, ko si itujade patiku.

⑦ Ìwọ̀n Ìwọ̀n: Ẹ̀ka alátakò ń dín ìwọ̀n kù ní pàtàkì.

⑧ Kemikali resistance: Asọṣe fun awọn agbegbe ibajẹ nipasẹ ohun elo / iṣakoso ilana.

Seramiki Vacuum Chuck VS Ibile Irin afamora Cup:

Seramiki igbale Chuck ni awọn semikondokito aaye

Seramiki igbale chucks sin bi clamping ati gbigbe irinṣẹ ni semikondokito wafer gbóògì. Wọn ṣe ẹya fifẹ giga ati afiwera, ipon ati ilana aṣọ, agbara giga, aye afẹfẹ ti o dara, agbara adsorption aṣọ, ati imura rọrun. Awọn abuda wọnyi jẹ ki wọn dara fun awọn ilana ni iṣelọpọ wafer semikondokito bii tinrin, slicing, lilọ, mimọ, ati mimu. Wọn koju awọn italaya ni imunadoko bii itusilẹ wafer, didenukole elekitiroti ti awọn eerun igi, ati idoti patiku, iyọrisi didara iṣelọpọ giga ga julọ fun awọn wafers semikondokito ni awọn ohun elo to wulo.

Iwe Data ti Awọn ohun elo seramiki

| Nkan | 95% aluminiomu | 99% aluminiomu | Zirconia | Silikoni carbide | SilikoniNitride | AluminiomuNitride |

| Àwọ̀ | funfun | Imọlẹ ofeefee | funfun | dudu | dudu | grẹy |

| Ìwúwo (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Gbigba Omi | 0% | 0% | 0% | 0% | 0% | 0% |

| Lile (HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Agbara Flexural (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Agbara Ipilẹṣẹ (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Ọdọmọkunrin Modulus Of Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Iye owo ti Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Gbona Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Dielectric Agbara | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Resistivity (25℃) | > 1014Ω·cm | > 1014Ω·cm | > 1014Ω·cm | > 105Ω·cm | > 1014Ω·cm | > 1014Ω·cm |

VET Energy jẹ olupese ọjọgbọn ti o fojusi lori R&D ati iṣelọpọ awọn ohun elo to ti ni ilọsiwaju giga-giga gẹgẹbi graphite, silikoni carbide, quartz, ati itọju ohun elo bii ibora SiC, ibora TaC, ideri carbon glassy, pyrolytic carbon cover, bbl Awọn ọja naa ni lilo pupọ ni fọtovoltaic, semikondokito, agbara tuntun, irin, ati bẹbẹ lọ.

Ẹgbẹ imọ-ẹrọ wa lati awọn ile-iṣẹ iwadii ile ti o ga julọ, le pese awọn solusan ohun elo alamọdaju diẹ sii fun ọ.

Awọn anfani Agbara VET pẹlu:

• Ti ara factory ati awọn ọjọgbọn yàrá;

• Awọn ipele mimọ ti ile-iṣẹ ati didara;

• Idije owo & Yara ifijiṣẹ akoko;

• Awọn ajọṣepọ ile-iṣẹ pupọ ni agbaye;

A ṣe itẹwọgba fun ọ lati wo ile-iṣẹ wa ati ile-iṣẹ ni eyikeyi akoko!