Ceramic Vacuum Chuck dị elu

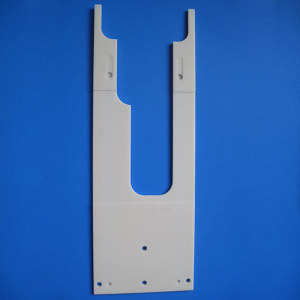

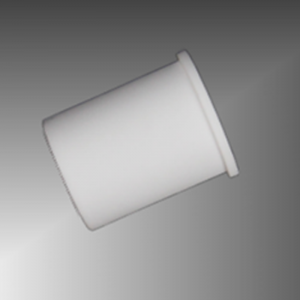

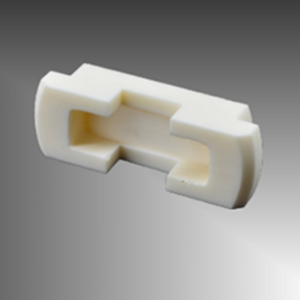

Ceramic Vacuum Chuck porousbụ ikpo okwu na-ebu ibu nke na-eji ụkpụrụ nke mgbasa ozi agụụ na-edozi ihe ndị na-arụ ọrụ. Akụkụ nke oghere oghere na-ebufe agụụ bụ efere seramiiki nwere oghere. A na-agbakọta efere seramiiki porous n'ime oghere imi nke ntọala ahụ, a na-ejikọta akụkụ ya ma mechie ya na isi. A na-eji seramiiki ziri ezi ma ọ bụ ihe ọla mee ntọala ahụ. Site na ijikọ a metal ma ọ bụ seramiiki isi na pụrụ iche porous seramiiki, imewe nke esịtidem nkenke ikuku ụzọ na-enye ohere maka ire ụtọ na kwụsie ike adhesion nke workpiece na agụụ mmiri mmiri iko mgbe doro n'okpuru nrụgide na-adịghị mma.

N'ihi pores dị oke mma na ceramics porous, elu nke workpiece nwere ike ịrapagidesi ike na iko mmiri na-enweghị ihe ọ bụla dị njọ dị ka ncha ma ọ bụ ihe nhụsianya kpatara nrụgide na-adịghị mma.

Àmà nke Ceramic Vacuum Chuck Porous:

① Okpokoro na otu ụdị: na-eguzogide ọgwụ silicon ntụ ntụ / ichikota ihe mkpofu, dị mfe ihicha.

② Ike dị elu & nguzogide iyi: Enweghị nrụrụ n'oge a na-egweri, na-ebelata njedebe ihu / nkewa.

③ Ogologo ndụ ogologo: Ndogide ọdịdị elu dị mma, ogologo mgbakwasa ogologo nwere obere mwepụ.

④ Ihe mkpuchi dị elu: Na-ewepụ ọkụ eletrik.

⑤ Enwere ike ijikwa ya & dị mfe iji ejiji: Enweghị mgbawa/chipping n'oge mweghachi, enwere ike ijikwa ọtụtụ ihe.

⑥ Na-abụghị uzuzu & kwụsie ike: zuru oke sintered, ọ dịghị urughuru umu anwuru.

⑦ Dị fechaa: Ọdịdị nke porous na-ebelata oke ibu.

⑧ Nguzogide kemịkalụ: Enwere ike ịhazi ya maka gburugburu corrosive site na njikwa ihe / usoro.

Ceramic Vacuum Chuck VS Ọdịnala Metal Suction Cup:

Ihe mgbochi seramiiki na mpaghara semiconductor

Igwe oghere seramiiki na-arụ ọrụ dị ka njide na iburu ngwaọrụ na mmepụta semiconductor wafer. Ha na-egosipụta ịdị larịị dị elu na myirịta, usoro dị oke na otu, ike dị elu, ikuku ikuku dị mma, ike adsorption otu, na mgbakwasa dị mfe. Njirimara ndị a na-eme ka ha dabara maka usoro na nrụpụta semiconductor wafer dị ka ịcha, slicing, egweri, ihicha na njikwa. Ha na-eleba anya nke ọma ihe ịma aka dị ka akara wafer, ndakpọ electrostatic nke ibe, na mmetọ ahụ, na-enweta ogo nhazi dị elu maka wafers semiconductor na ngwa bara uru.

Mpempe akwụkwọ data nke ngwa seramiiki

| Ihe | 95% aluminum | 99% aluminum | Zirconia | Silicon carbide | SilikoniNitride | AluminomNitride |

| Agba | ọcha | Ọcha edo edo | ọcha | nwa | nwa | agba ntụ |

| Njupụta (g/cm3) | 3.7g / cm3 | 3.9g / cm3 | 6.02g / cm3 | 3.2g / cm3 | 3.25g / cm3 | 3.2g / cm3 |

| Mmiri Absorption | 0% | 0% | 0% | 0% | 0% | 0% |

| Isi ike (HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Ike Flexural (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Ike mkpakọ (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Modul nke ntorobịa nke ngbanwe | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Oke Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Nrụpụta okpomọkụ | 20W/mºC | 32W/mºC | 3W/mºC | 50W/mºC | 25W/mºC | 150W/m°C |

| Ike Dielectric | 14KV / mm | 14KV / mm | 14KV / mm | 14KV / mm | 14KV / mm | 14KV / mm |

| Nkwụghachi olu (25 ℃) | > 1014Ω·cm | > 1014Ω·cm | > 1014Ω·cm | > 105Ω·cm | > 1014Ω·cm | > 1014Ω·cm |

VET Energy bụ ọkachamara emeputa na-elekwasị anya na R & D na mmepụta nke elu-ọgwụgwụ elu ihe dị ka graphite, silicon carbide, quartz, nakwa dị ka ihe ọgwụgwọ dị ka SiC mkpuchi, TaC mkpuchi, glassy carbon mkpuchi, pyrolytic carbon mkpuchi, wdg The ngwaahịa na-ọtụtụ-eji na fotovoltaic, semiconductor, ọhụrụ ume, metallurgy, wdg.

Anyị oru otu si n'elu ụlọ nnyocha ụlọ ọrụ, nwere ike na-enye ndị ọzọ ọkachamara ihe ngwọta maka gị.

Uru VET Energy gụnyere:

• Ụlọ ọrụ mmepụta ihe na ụlọ nyocha ọkachamara;

• Ụlọ ọrụ na-eduga ọkwa dị ọcha na ịdị mma;

• Ọnụ ahịa asọmpi & oge nnyefe ngwa ngwa;

• Mmekọrịta ọtụtụ ụlọ ọrụ n'ụwa nile;

Anyị na-anabata gị ka vist anyị factory na laabu n'oge ọ bụla!