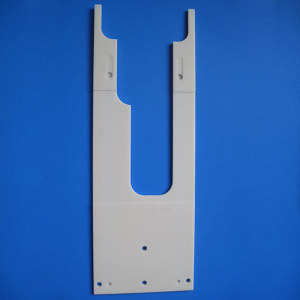

Chuck e tsoetseng pele ea Porous Ceramic Vacuum

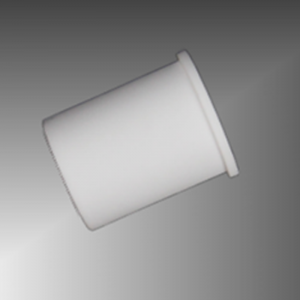

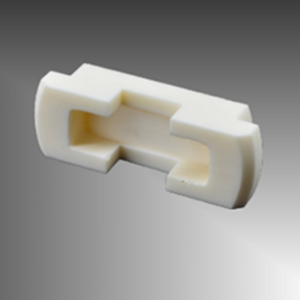

Porous Ceramic Vacuum Chuckke sethala se jereng mojaro se sebelisang molao-motheo oa vacuum adsorption ho lokisa li-workpieces. Karolo ea vacuum chuck e fetisang vacuum ke poleiti e nang le porous ceramic. Letlapa le nang le porous ceramic le bokelloa ka mokoting o tebang oa setsi, 'me sebaka sa eona se kopantsoe le ho tiisoa ka motheo. Motheo o entsoe ka lisebelisoa tse nepahetseng tsa ceramic kapa tsa tšepe. Ka ho kopanya motheo oa tšepe kapa oa ceramic o nang le ceramic e khethehileng ea porous, moralo oa tsela e nepahetseng ea ka hare ea moea e lumella ho khomarela boreleli le ho tsitsisa ha sesebediswa sa mosebetsi ho senoelo sa ho huloa ha vacuum ha se tlas'a khatello e mpe.

Ka lebaka la li-pores tse ntle ka ho fetesisa ka har'a li-ceramics tse nang le porous, bokaholimo ba sesebelisoa bo ka khomareloa ka har'a kopi ea vacuum suction ntle le mabaka a mang a mabe joalo ka mengoapo kapa menoana a bakoang ke khatello e mpe.

Litšobotsi tsa Porous Ceramic Vacuum Chuck:

① Sebopeho se teteaneng le se ts'oanang: E hanana le phofo ea silicon / adsorption ea maloanlahla a sila, ho bonolo ho e hloekisa.

② Matla a phahameng le khanyetso ea ho roala: Ha ho na deformation nakong ea ho sila, e fokotsa ho phunya / ho arohana.

③ Nako e telele ea bophelo: Ho boloka sebopeho se setle sa bokaholimo, nako e telele ea ho roala le ho tlosoa hanyane.

④ Insulation e phahameng: E felisa motlakase o sa fetoheng.

⑤ E ka sebelisoa hape 'me ho bonolo ho e apara: Ha ho na ho petsoha / ho petsoha nakong ea ho tsosolosa, ho sebelisoa hangata.

⑥ Ha e na lerōle ebile e tsitsitse: E sirelelitsoe ka botlalo, ha e na tlhahiso ea likaroloana.

⑦ Boima bo bobebe: Sebopeho sa porous se fokotsa boima ba 'mele haholo.

⑧ Khanyetso ea lik'hemik'hale: E ka tloaeleha bakeng sa tikoloho e senyang ka taolo ea lisebelisoa / ts'ebetso.

Ceramic Vacuum Chuck VS Traditional Metal Suction Cup:

Ceramic vacuum chuck tšimong ea semiconductor

Ceramic vacuum chucks e sebetsa e le lisebelisoa tsa ho koala le ho jara tlhahiso ea semiconductor wafer. Li na le botala bo phahameng le ho bapisa, sebopeho se teteaneng le se ts'oanang, matla a phahameng, ho kenella hantle ha moea, matla a adsorption a tšoanang, le ho apara habonolo. Litšobotsi tsena li li etsa hore li tšoanelehe bakeng sa lits'ebetso tsa tlhahiso ea semiconductor wafer joalo ka ho fokotsa, ho seha, ho sila, ho hloekisa le ho sebetsana. Ba sebetsana ka katleho le liqholotso tse kang ho hatisoa ha li-wafer, ho senyeha ha li-chips tsa electrostatic, le tšilafalo ea likaroloana, ho finyella boleng bo phahameng ka ho fetisisa ba ho sebetsana le li-wafer tsa semiconductor lits'ebetsong tse sebetsang.

Leqephe la Lintlha tsa Lisebelisoa tsa Ceramic

| Ntho | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | SiliconeNitride | AluminiumNitride |

| Mmala | tšoeu | Bosehla bo kganyang | tšoeu | ntsho | ntsho | bohlooho |

| Boima ba 'mele (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Ho Monyeha ha Metsi | 0% | 0% | 0% | 0% | 0% | 0% |

| Ho thatafala(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Flexural Strength (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Compressive Strength (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Modulus ea Mocha oa Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Karolelano ea Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Matla a Dielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ho hanyetsa Bophahamo (25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

VET Energy ke moetsi ea hloahloa o shebaneng le R&D le tlhahiso ea lisebelisoa tse tsoetseng pele tse phahameng joalo ka graphite, silicon carbide, quartz, hammoho le kalafo ea thepa e kang SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, joalo-joalo Lihlahisoa li sebelisoa haholo ho photovoltaic, semiconductor, matla a macha, metallurgy, joalo-joalo.

Sehlopha sa rona sa tekheniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, se ka u fa litharollo tsa lisebelisoa tse eketsehileng bakeng sa hau.

Melemo ea Matla a VET e kenyelletsa:

• Femetheri le laboratori ea litsebi;

• Maemo a bohloeki a etelletseng pele indastering le boleng;

• Theko ea tlhōlisano & Nako ea ho fana ka potlako;

• Litšebelisano tse ngata tsa indasteri lefatšeng ka bophara;

Re u amohela ho bona feme le laboratori ea rona ka nako efe kapa efe!

-

Semiconductor Alumina Ceramic Plate

-

Seketsoana sa Quartz se Phahameng sa Bohloeki bakeng sa Ts'ebetso ea Wafer

-

Mocheso o phahameng oa tloaelo le ho bola ha kutu...

-

Bohloeki bo phahameng ba alumina ceramic Mechanical letsoho

-

Alumina ceramics Sekoahelo sa Semiconductor Insulating

-

Semiconductor Alumina ceramics Insulating Cover