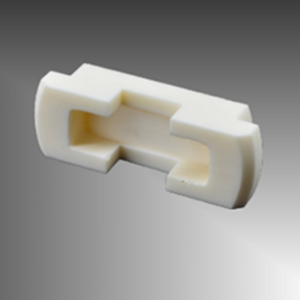

Advanced Porous Ceramic Vacuum Chuck

Porous Ceramic Vacuum Chuck is a load-bearing platform that uses the principle of vacuum adsorption to fix workpieces. The part of the vacuum chuck that transmits vacuum is a porous ceramic plate. The porous ceramic plate is assembled in the sinking hole of the base, and its periphery is bonded and sealed with the base. The base is made of precision ceramic or metal materials. By combining a metal or ceramic base with a special porous ceramic, the design of the internal precision airway allows for smooth and stable adhesion of the workpiece to the vacuum suction cup when subjected to negative pressure.

Due to the extremely fine pores in porous ceramics, the surface of the workpiece can be adhered to the vacuum suction cup without any adverse factors such as scratches or dents caused by negative pressure.

Characteristics of Porous Ceramic Vacuum Chuck:

① Dense & uniform structure: Resists silicon powder/grinding debris adsorption, easy to clean.

② High strength & wear resistance: No deformation during grinding, minimizes edge chipping/fragmentation.

③ Long lifespan: Excellent surface shape retention, long dressing cycle with minimal removal.

④ High insulation: Eliminates static electricity.

⑤ Reusable & easy to dress: No cracking/chipping during resurfacing, multiple reuse possible.

⑥ Non-dusting & stable: Fully sintered, no particle emission.

⑦ Lightweight: Porous structure reduces weight significantly.

⑧ Chemical resistance: Customizable for corrosive environments via material/process control.

Ceramic Vacuum Chuck VS Traditional Metal Suction Cup:

Ceramic vacuum chuck in the semiconductor field

Ceramic vacuum chucks serve as clamping and carrying tools in semiconductor wafer production. They feature high flatness and parallelism, a dense and uniform structure, high strength, good air permeability, uniform adsorption force, and easy dressing. These characteristics make them suitable for processes in semiconductor wafer manufacturing such as thinning, slicing, grinding, cleaning, and handling. They effectively address challenges like wafer imprinting, electrostatic breakdown of chips, and particle contamination, achieving extremely high processing quality for semiconductor wafers in practical applications.

Data Sheet of Ceramic Materials

| Item | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | Silicon Nitride | Aluminum Nitride |

| Colour | white | Light yellow | white | black | black | gray |

| Density (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Water Absorption | 0% | 0% | 0% | 0% | 0% | 0% |

| Hardness(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Flexural Strength (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Compressive Strength (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Young's Modulus Of Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310~350GPa |

| Poisson's Ratio | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Dielectric Strength | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Volume Resistivity(25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

VET Energy is a professional manufacturer focusing on the R&D and production of high-end advanced materials such as graphite, silicon carbide, quartz, as well as the material treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc. The products are widely used in photovoltaic, semiconductor, new energy, metallurgy, etc..

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

VET Energy advantages includes:

• Own factory and professional laboratory;

• Industry-leading purity levels and quality;

• Competive price & Fast delivery time;

• Multiple industry partnerships worldwide;

We welcome you to vist our factory and laboratory at any time!