Advanced Porous Ceramic Nqus Chuck

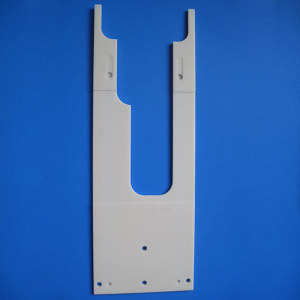

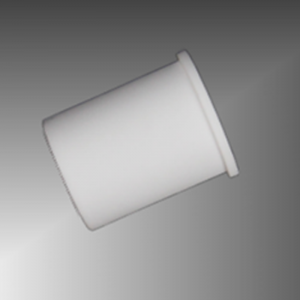

Porous Ceramic Nqus Chuckyog lub platform load-bearing uas siv lub hauv paus ntsiab lus ntawm lub tshuab nqus tsev adsorption los kho workpieces. Ib feem ntawm lub tshuab nqus tsev chuck uas xa lub tshuab nqus tsev yog ib lub phaj ntxeem tau. Cov porous ceramic phaj yog sib sau ua ke nyob rau hauv lub dab dej ntawm lub hauv paus, thiab nws periphery yog bonded thiab kaw nrog lub hauv paus. Lub hauv paus yog ua los ntawm precision ceramic lossis hlau cov ntaub ntawv. Los ntawm kev sib txuas cov hlau los yog ceramic puag nrog tshwj xeeb ntxeem tau ceramic, tus tsim ntawm lub sab hauv precision airway tso cai rau du thiab ruaj khov adhesion ntawm lub workpiece mus rau lub tshuab nqus tsev nqus khob thaum raug lub siab tsis zoo.

Vim tias qhov pores zoo heev hauv cov porous ceramics, qhov saum npoo ntawm lub workpiece tuaj yeem ua rau lub tshuab nqus tsev nqus tsev yam tsis muaj qhov tsis zoo xws li khawb los yog dents los ntawm qhov tsis zoo.

Cov yam ntxwv ntawm Porous Ceramic Nqus Chuck:

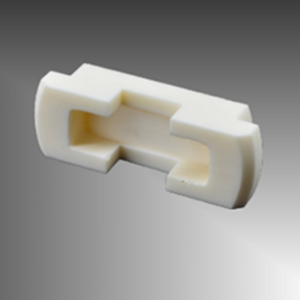

① Dense & Uniform qauv: resistays silicon hmoov / sib tsoo cov khib nyiab adsorption, yooj yim los ntxuav.

② Lub zog siab & hnav tsis kam: Tsis muaj deformation thaum sib tsoo, txo qis ntug chipping / fragmentation.

③ Ntev lifespan: zoo heev nto zoo tuav, ntev hnav khaub ncaws voj voog nrog tsawg heev tshem tawm.

④ High rwb thaiv tsev: tshem tawm hluav taws xob zoo li qub.

⑤ Reusable & yooj yim rau hnav: Tsis muaj cracking / chipping thaum resurfacing, ntau yam rov qab siv tau.

⑥ Tsis-plua plav & ruaj khov: Siab sintered, tsis muaj particle emission.

⑦ Lub teeb yuag: Porous qauv txo qhov hnyav heev.

⑧ Tshuaj tiv thaiv: Customizable rau corrosive ib puag ncig ntawm cov khoom / txheej txheem tswj.

Ceramic Vacuum Chuck VS Traditional Metal Suction Cup:

Ceramic nqus chuck nyob rau hauv semiconductor teb

Ceramic nqus chucks ua haujlwm clamping thiab nqa cov cuab yeej hauv semiconductor wafer ntau lawm. Lawv muaj cov qauv kev sib luag thiab kev sib tw thiab cov qauv sib dhos, muaj zog, huab cua zoo nkauj, thiab kev hnav khaub ncaws zoo nkauj, thiab kev hnav khaub ncaws zoo nkauj. Cov yam ntxwv no ua rau lawv tsim nyog rau cov txheej txheem hauv semiconductor wafer manufacturing xws li thinning, slicing, sib tsoo, tu, thiab tuav. Lawv daws cov teeb meem zoo li wafer imprinting, electrostatic tawg ntawm cov chips, thiab cov kab mob sib kis, ua tiav kev ua haujlwm siab heev rau cov khoom siv hluav taws xob semiconductor hauv cov ntawv thov.

Cov ntaub ntawv ntawm cov ntaub ntawv ceramic

| Yam khoom | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | SiliconNitride | AluminiumNitride |

| Xim | dawb | Lub teeb daj | dawb | dub | dub | grey |

| Qhov ceev (g / cm3) | 3.7g / cm3 | 3.9g / cm3 | 6.02 g / cm3 | 3.2g / cm3 | 3.25g / cm3 | 3.2g / cm3 |

| Kev nqus dej | 0% | 0% | 0% | 0% | 0% | 0% |

| Hardness (HV) | 23.7 ib | 23.7 ib | 16.5 ib | 33 | 20 | - |

| Flexural zog (MPa) | 300MPa | 400 MPa | 1100MPa | 450 MPa | 800MPa | 310 MPa |

| Compressive zog (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600 MPa | - |

| Young's Modulus Ntawm Elasticity | 300 GP ua | 300 GP ua | 320 GP ua | 450 GP ua | 290 gp ua | 310 ~ 350 GPa |

| Poisson tus ratio | 0.23 | 0.23 | 0.25 | 0.14 ib | 0.24 ib | 0.24 ib |

| Thermal conductivity | 20 W / m ° C | 32 W / m ° C | 3 W / m ° C | 50 W / m ° C | 25 W / m ° C | 150 W / m ° C |

| Dielectric zog | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli |

| Volume Resistivity (25 ℃) | > 1014Ω·cm | > 1014Ω·cm | > 1014Ω·cm | > 105Ω·cm | > 1014Ω·cm | > 1014Ω·cm |

VET Energy yog cov chaw tsim khoom lag luam tsom rau R&D thiab tsim cov khoom siv siab kawg xws li graphite, silicon carbide, quartz, nrog rau cov khoom siv kho mob xws li SiC txheej, TaC txheej, iav carbon txheej, pyrolytic carbon txheej, thiab lwm yam. Cov khoom siv dav siv hauv photovoltaic, semiconductor, tshiab zog, metallurgy, thiab lwm yam.

Peb pab neeg ua haujlwm los ntawm cov tsev kawm tshawb fawb saum toj kawg nkaus hauv tebchaws, tuaj yeem muab cov ntaub ntawv tshaj lij tshaj lij rau koj.

VET Energy zoo muaj xws li:

• Tus kheej lub Hoobkas thiab kev kuaj xyuas;

• Kev lag luam-ua purity theem thiab zoo;

• Tus nqi sib tw & Lub sijhawm xa khoom sai;

• Ntau lub koom haum kev lag luam thoob ntiaj teb;

Peb zoo siab tos txais koj tuaj xyuas peb lub Hoobkas thiab chav kuaj txhua lub sijhawm!