Okuthuthukisiwe kwe-Porous Ceramic Vacuum Chuck

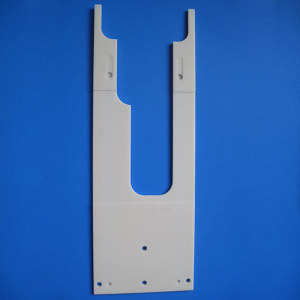

I-Porous Ceramic Vacuum Chuckiyinkundla ethwala imithwalo esebenzisa umgomo we-vacuum adsorption ukulungisa ama-workpieces. Ingxenye ye-vacuum chuck ehambisa i-vacuum iyipuleti le-ceramic elinezimbotshana. Ipuleti le-ceramic elinezimbotshana lihlanganiswe emgodini ozikayo wesisekelo, futhi i-periphery yalo iboshiwe futhi ivalwe ngesisekelo. Isisekelo senziwa ngokunemba kwe-ceramic noma izinto zensimbi. Ngokuhlanganisa isisekelo sensimbi noma se-ceramic ne-ceramic ekhethekile enezimbotshana, idizayini yomzila womoya onembile wangaphakathi ivumela ukunamathela okubushelelezi nokuzinzile kwendawo yokusebenza enkomishini yokudonsa i-vacuum lapho ingaphansi kwengcindezi engemihle.

Ngenxa yezimbotshana ezinhle kakhulu kuma-porous ceramics, ingaphezulu le-workpiece linganamathela enkomishini yokumunca i-vacuum ngaphandle kwanoma yiziphi izici ezingezinhle njengokuklwebheka noma amazinyo okubangelwa ingcindezi engemihle.

Izici ze-Porous Ceramic Vacuum Chuck:

① Isakhiwo esiminyene nesifanayo: Imelana ne-silicon powder/ukugaya imfucumfucu i-adsorption, kulula ukuyihlanza.

② Amandla aphezulu nokumelana nokugqokwa: Akukho ukuguquguquka ngesikhathi sokugaya, kunciphisa ukuchotshozwa/ukuhlukana konqenqema.

③ Ukuphila okude: Ukugcinwa komumo omuhle kakhulu wendawo, umjikelezo omude wokugqokisa nokususwa okuncane.

④ I-insulation ephezulu: Iqeda ugesi omile.

⑤ Isebenziseka kabusha futhi kulula ukuyigqoka: Akukho ukuqhekeka/ukuqhekeka ngesikhathi sokufakwa kabusha, ukusetshenziswa kabusha okuningi kungenzeka.

⑥ Okungathuli futhi kuzinzile: I-sintered ngokugcwele, akukho kukhishwa kwezinhlayiyana.

⑦ I-Lightweight: Isakhiwo se-Porous sinciphisa isisindo kakhulu.

⑧ Ukumelana namakhemikhali: Kwenziwa ngendlela oyifisayo ezindaweni ezonakalisayo ngokulawulwa kwezinto/inqubo.

I-Ceramic Vacuum Chuck VS Traditional Metal Suction Cup:

I-Ceramic vacuum chuck ensimini ye-semiconductor

Ama-chucks e-Ceramic vacuum asebenza njenge-clamping kanye namathuluzi okuphatha ekukhiqizeni i-wafer ye-semiconductor. Zibonisa ukucaba okuphakeme nokuhambisana, isakhiwo esiminyene nesifanayo, amandla aphezulu, ukungena komoya okuhle, amandla okukhangisa afanayo, nokugqoka kalula. Lezi zici zizenza zilungele izinqubo zokwenziwa kwe-wafer ye-semiconductor njengokuphungula, ukusika, ukugaya, ukuhlanza, nokuphatha. Babhekana ngokuphumelelayo nezinselele ezifana ne-wafer imprinting, ukuwohloka kwe-electrostatic yama-chips, nokungcoliswa kwezinhlayiyana, ukufeza ikhwalithi yokucubungula ephezulu kakhulu yama-wafers we-semiconductor ekusebenzeni okungokoqobo.

Ishidi Ledatha Lezinto Zobumba

| Into | 95% Alumina | 99% Alumina | I-Zirconia | I-silicon carbide | I-siliconNhamba | I-AluminiumNhamba |

| Umbala | mhlophe | Okuphuzi okukhanyayo | mhlophe | mnyama | mnyama | impunga |

| Ukuminyana (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Ukumuncwa Amanzi | 0% | 0% | 0% | 0% | 0% | 0% |

| Ukuqina(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Amandla e-Flexural (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Amandla Acindezelayo (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| I-Young's Modulus Of Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Isilinganiso sikaPoisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| I-Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Amandla e-Dielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ukungazweli Ivolumu(25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

I-VET Energy ingumkhiqizi ochwepheshile ogxile ku-R&D nasekukhiqizeni izinto ezithuthukile ezisezingeni eliphezulu njengegraphite, i-silicon carbide, i-quartz, kanye nokwelapha okuphathekayo okufana ne-SiC coating, i-TaC coating, i-glassy carbon coating, i-pyrolytic carbon coating, njll. Imikhiqizo isetshenziswa kabanzi ku-photovoltaic, semiconductor, amandla amasha njll.

Ithimba lethu lezobuchwepheshe livela ezikhungweni eziphezulu zocwaningo lwasekhaya, lingakunikeza izixazululo zempahla echwepheshile.

Izinzuzo ze-VET Energy zihlanganisa:

• Ifekthri kanye nelabhorethri yochwepheshe;

• Amazinga okuhlanzeka okuhamba phambili embonini kanye nekhwalithi;

• Intengo yokuncintisana nesikhathi sokulethwa okusheshayo;

• Ubambiswano lwezimboni eziningi emhlabeni wonke;

Siyakwamukela ukuthi uvakashele imboni yethu kanye nelabhorethri nganoma yisiphi isikhathi!

-

Semiconductor Alumina Ceramic Plate

-

Isikebhe seQuartz Esihlanzekile Sokucutshungulwa kwe-Wafer

-

Izinga lokushisa eliphezulu ngokwezifiso nokumelana nokugqwala...

-

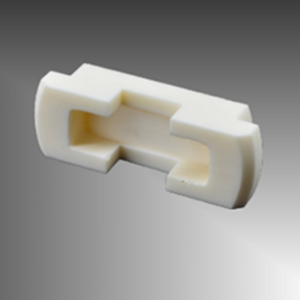

Ukuhlanzeka okuphezulu kwe-alumina ceramic Ingalo yomshini

-

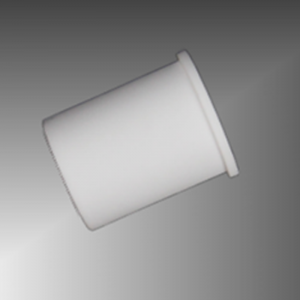

Ikhava ye-Alumina ceramics Semiconductor Insulating Cover

-

Semiconductor Alumina ceramics Insulating Cover