Ceramic Wafer Heater AlN Alumina Heating Element

Ha ho etsoa li-semiconductor, li-wafers li hloka ho sebetsoa ka mekhoa e fapaneng, joalo ka ho beoa ha filimi e tšesaane, etching, joalo-joalo Lihokelong tsena, li-wafers li hloka ho futhumatsoa ka mocheso o itseng, 'me ho na le litlhoko tse tiileng tsa mocheso, hobane ho tšoana ha mocheso ho na le phello ea bohlokoa haholo tlhahisong ea sehlahisoa, mme likarolo tsa ho futhumatsa li bohlokoa haholo.

Mofuthu oa ceramice sebelisoa ka ho toba kamoreng ea ts'ebetso 'me e kopane ka ho toba le sephaphatha. Ha ba jare sephaphatha feela, empa hape ba netefatsa hore sephaphatha se fumana mocheso o tsitsitseng le o ts'oanang oa ts'ebetso. Ke likarolo tsa bohlokoa ka har'a lisebelisoa tsa ho beha lifilimi tse tšesaane tsa semiconductor!

Mofuthu oa ceramic o kenyelletsa setsi sa ceramic se tšehetsang sephaphatha le 'mele oa tšehetso oa cylindrical ka lehlakoreng le ka morao le o tšehetsang. Ntle le karolo ea ho hanyetsa (ho futhumatsa) bakeng sa ho futhumatsa, ho boetse ho na le li-electrode tsa radio frequency (RF layer) ka hare kapa ka holim'a setsi sa ceramic. E le ho finyella ho futhumatsa ka potlako le ho pholile, botenya ba setsi sa ceramic bo lokela ho ba bo fokolang, empa bo fokolang haholo bo tla fokotsa ho tiea.

Tšehetso ea heater ea ceramic hangata e entsoe ka thepa ea ceramic e nang le coefficient ea ho atolosa mocheso e tšoanang le ea setsi. Mofuthu o amohela sebopeho se ikhethileng sa karolo e ka tlase e kopaneng ea shaft ho sireletsa liteishene le lithapo ho litlamorao tsa plasma le likhase tsa lik'hemik'hale tse senyang. Ts'ehetso e na le phallo ea khase e fetisang mocheso le phaephe ea ho tsoa ho netefatsa mocheso o ts'oanang oa hitara. Motheo le tšehetso li kopantsoe ka lik'hemik'hale ka lera le tlamang.

Mofuthu oa ceramic o ka etsoa ka lirafshoa tse kang aluminium nitride (AlN), silicon nitride (Si3N4), le alumina (Al2O3). Har'a bona, AlN ke khetho e ntle ka ho fetisisa bakeng sa li-heaters tsa ceramic. Ha ho bapisoa le lisebelisoa tse ling, VET Energy's AlN ceramic e na le litšobotsi tse latelang:

(1) Ts'ebetso e ntle ea mocheso;

(2) E tsamaellana le coefficient ea ho atolosa mocheso ho lisebelisoa tsa silicon tsa semiconductor;

(3) Thepa e ntle ea mochini, ho hanyetsa ka mokhoa o motle haholo, le thepa e felletseng ea mochini e ntle ho feta beryllium oxide mme e lekana le aluminium oxide;

(4) Thepa e ntle haholo ea motlakase e felletseng, ho kenella ka motlakase ho matla le tahlehelo e tlase ea dielectric;

(5) E seng chefo le tikoloho.

Leqephe la Lintlha tsa Lisebelisoa tsa Ceramic

| Ntho | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | SiliconeNitride | AluminiumNitride |

| Mmala | tšoeu | Bosehla bo kganyang | tšoeu | ntsho | ntsho | bohlooho |

| Boima ba 'mele (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Ho Monyeha ha Metsi | 0% | 0% | 0% | 0% | 0% | 0% |

| Ho thatafala(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Flexural Strength (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Compressive Strength (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Modulus ea Mocha oa Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Karolelano ea Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Matla a Dielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ho hanyetsa Bophahamo (25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

VET Energy ke moetsi ea hloahloa o shebaneng le R&D le tlhahiso ea lisebelisoa tse tsoetseng pele tse phahameng joalo ka graphite, silicon carbide, quartz, hammoho le kalafo ea thepa e kang SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, joalo-joalo Lihlahisoa li sebelisoa haholo ho photovoltaic, semiconductor, matla a macha, metallurgy, joalo-joalo.

Sehlopha sa rona sa tekheniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, se ka u fa litharollo tsa lisebelisoa tse eketsehileng bakeng sa hau.

Melemo ea Matla a VET e kenyelletsa:

• Femetheri le laboratori ea litsebi;

• Maemo a bohloeki a etelletseng pele indastering le boleng;

• Theko ea tlhōlisano & Nako ea ho fana ka potlako;

• Litšebelisano tse ngata tsa indasteri lefatšeng ka bophara;

Re u amohela ho bona feme le laboratori ea rona ka nako efe kapa efe!

-

Semiconductor Alumina ceramics Insulating Cover

-

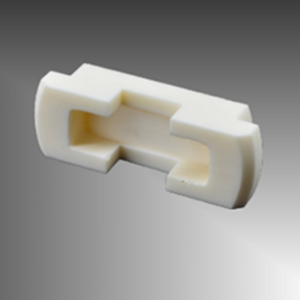

Semiconductor Alumina ceramics Wafer Carrier

-

Alumina ceramics Sekoahelo sa Semiconductor Insulating

-

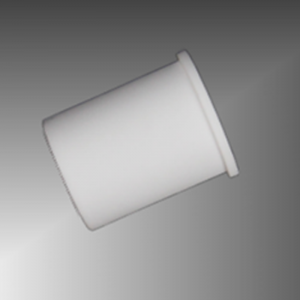

Alumina Ceramic Semiconductor electrode sleeve

-

Mocheso o phahameng oa tloaelo le ho bola ha kutu...

-

Sekontiri se phahameng sa quartz se sebelisitsoeng ho photovo ...