Ceramic Wafer rhaub AlN Alumina Cua sov Element

Nyob rau hauv semiconductor manufacturing, wafers yuav tsum tau ua nyob rau hauv ntau yam txheej txheem, xws li nyias zaj duab xis deposition, etching, thiab lwm yam. Nyob rau hauv cov kev sib txuas, cov wafers yuav tsum tau rhuab mus rau ib tug tej yam kub thiab txias, vim hais tias cov uniformity ntawm kub muaj ib tug tseem ceeb heev cuam tshuam rau cov khoom yield, thiab cua sov Cheebtsam yog indispensable.

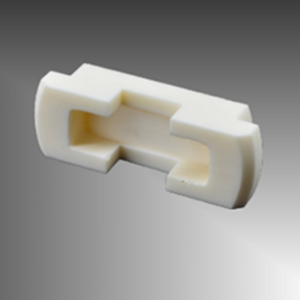

Ceramic rhaubyog siv ncaj qha mus rau cov txheej txheem chamber thiab nyob rau hauv kev sib cuag ncaj qha nrog lub wafer. Lawv tsis tsuas yog nqa lub wafer xwb, tab sis kuj xyuas kom meej tias lub wafer tau txais qhov kub thiab txias txheej txheem. Lawv yog cov khoom tseem ceeb hauv cov khoom siv semiconductor nyias zaj duab xis tso tawm!

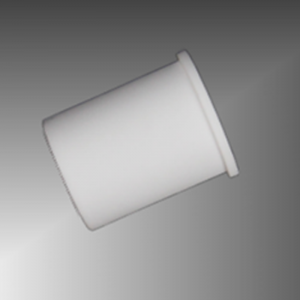

Lub tshuab rhaub ceramic suav nrog lub hauv paus ceramic uas txhawb nqa lub wafer thiab lub cev txhawb nqa cylindrical nyob rau sab nraub qaum uas txhawb nqa nws. Ntxiv rau cov khoom siv hluav taws xob (cov cua sov txheej) rau cov cua sov, kuj tseem muaj cov xov tooj cua zaus electrodes (RF txheej) sab hauv lossis rau saum npoo ntawm lub hauv paus ceramic. Yuav kom ua tiav cov cua kub ceev thiab txias, lub thickness ntawm lub hauv paus ceramic yuav tsum nyias, tab sis nyias nyias kuj yuav txo tau qhov rigidity.

Kev txhawb nqa ntawm lub tshuab rhaub ceramic feem ntau yog ua los ntawm cov khoom siv ceramic nrog cov thermal expansion coefficient zoo ib yam li cov hauv paus. Lub tshuab rhaub tau txais cov qauv tshwj xeeb ntawm cov ncej sib koom hauv qab los tiv thaiv cov terminals thiab cov xov hlau los ntawm cov teebmeem ntawm cov plasma thiab corrosive chemical gases. Cov kev txhawb nqa yog nruab nrog lub tshav kub hloov roj inlet thiab qhov hluav taws xob yeeb nkab kom ntseeg tau tias qhov kub thiab txias ntawm lub rhaub. Lub hauv paus thiab kev txhawb nqa yog chemically bonded nrog cov txheej txheem sib txuas.

Lub tshuab rhaub ceramic tuaj yeem ua los ntawm ceramics xws li txhuas nitride (AlN), silicon nitride (Si3N4), thiab alumina (Al2O3). Ntawm lawv, AlN yog qhov kev xaiv zoo tshaj plaws rau cov cua sov ceramic. Piv nrog rau lwm cov ntaub ntawv, VET Energy's AlN ceramic muaj cov yam ntxwv hauv qab no:

(1) Zoo thermal conductivity;

(2) Sib piv thermal expansion coefficient rau semiconductor silicon cov ntaub ntawv;

(3) Cov khoom siv kho tshuab zoo, zoo heev hnav tsis kam, thiab cov khoom siv dav dav zoo dua li beryllium oxide thiab sib npaug rau txhuas oxide;

(4) Cov khoom siv hluav taws xob zoo heev, hluav taws xob rwb thaiv tsev zoo heev thiab tsis muaj dielectric poob;

(5) Non-toxic thiab environmentally friendly.

Cov ntaub ntawv ntawm cov ntaub ntawv ceramic

| Yam khoom | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | SiliconNitride | AluminiumNitride |

| Xim | dawb | Lub teeb daj | dawb | dub | dub | grey |

| Qhov ceev (g / cm3) | 3.7g / cm3 | 3.9g / cm3 | 6.02 g / cm3 | 3.2g / cm3 | 3.25g / cm3 | 3.2g / cm3 |

| Kev nqus dej | 0% | 0% | 0% | 0% | 0% | 0% |

| Hardness (HV) | 23.7 ib | 23.7 ib | 16.5 ib | 33 | 20 | - |

| Flexural zog (MPa) | 300MPa | 400 MPa | 1100MPa | 450 MPa | 800MPa | 310 MPa |

| Compressive zog (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600 MPa | - |

| Young's Modulus Ntawm Elasticity | 300 GP ua | 300 GP ua | 320 GP ua | 450 GP ua | 290 gp ua | 310 ~ 350 GPa |

| Poisson tus ratio | 0.23 | 0.23 | 0.25 | 0.14 ib | 0.24 ib | 0.24 ib |

| Thermal conductivity | 20 W / m ° C | 32 W / m ° C | 3 W / m ° C | 50 W / m ° C | 25 W / m ° C | 150 W / m ° C |

| Dielectric zog | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli |

| Volume Resistivity (25 ℃) | > 1014Ω·cm | > 1014Ω·cm | > 1014Ω·cm | > 105Ω·cm | > 1014Ω·cm | > 1014Ω·cm |

VET Energy yog cov chaw tsim khoom lag luam tsom rau R&D thiab tsim cov khoom siv siab kawg xws li graphite, silicon carbide, quartz, nrog rau cov khoom siv kho mob xws li SiC txheej, TaC txheej, iav carbon txheej, pyrolytic carbon txheej, thiab lwm yam. Cov khoom siv dav siv hauv photovoltaic, semiconductor, tshiab zog, metallurgy, thiab lwm yam.

Peb pab neeg ua haujlwm los ntawm cov tsev kawm tshawb fawb saum toj kawg nkaus hauv tebchaws, tuaj yeem muab cov ntaub ntawv tshaj lij tshaj lij rau koj.

VET Energy zoo muaj xws li:

• Tus kheej lub Hoobkas thiab kev kuaj xyuas;

• Kev lag luam-ua purity theem thiab zoo;

• Tus nqi sib tw & Lub sijhawm xa khoom sai;

• Ntau lub koom haum kev lag luam thoob ntiaj teb;

Peb zoo siab tos txais koj tuaj xyuas peb lub Hoobkas thiab chav kuaj txhua lub sijhawm!