Isifudumezi-sifudumezi seCeramic AlN Alumina Element yokuFundisa

Kwimveliso ye-semiconductor, ii-wafers kufuneka zicutshungulwe kwiinkqubo ezahlukeneyo, ezifana ne-deposition yefilimu ebhityileyo, i-etching, njl. Kwezi khonkco, ii-wafers kufuneka zifudunyezwe kwiqondo elithile lobushushu, kwaye kukho iimfuno ezingqongqo kwiqondo lokushisa, kuba ukufana kweqondo lokushisa kunempembelelo ebaluleke kakhulu kwimveliso yemveliso, kwaye izinto zokufudumeza ziyimfuneko.

Isifudumezi seCeramicisetyenziswe ngokuthe ngqo kwigumbi lenkqubo kwaye idibene ngokuthe ngqo ne-wafer. Abagcini nje ngokuthwala i-wafer, kodwa baqinisekisa ukuba i-wafer ifumana iqondo lokushisa elizinzileyo kunye nelinye. Zingamacandelo aphambili kwi-semiconductor encinci yezixhobo zokubeka ifilimu!

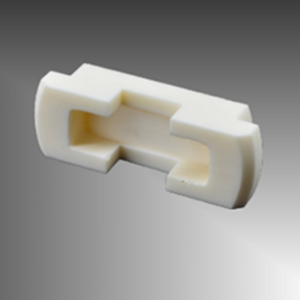

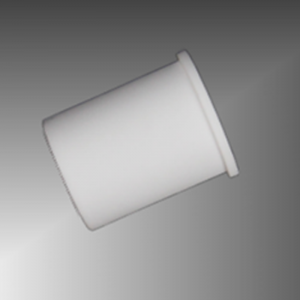

I-heater ye-ceramic iquka isiseko se-ceramic esixhasa i-wafer kunye ne-cylindrical support body on the back side that support it. Ukongeza kwinto yokumelana (i-heater) yokufudumeza, kukho kwakhona i-electrodes yerediyo (i-RF layer) ngaphakathi okanye kumphezulu wesiseko se-ceramic. Ukuze ufezekise ukufudumeza ngokukhawuleza kunye nokupholisa, ubukhulu besiseko se-ceramic kufuneka bube buncinci, kodwa buncinci kakhulu buya kunciphisa ukuqina.

Inkxaso ye-ceramic heater yenziwa ngokubanzi ngezinto ze-ceramic kunye ne-coefficient yokwandisa i-thermal efana nesiseko. I-heater ithatha isakhiwo esiyingqayizivele se-shaft joint bottom ukukhusela i-terminals kunye neengcingo kwimiphumo ye-plasma kunye neegesi zekhemikhali ezinobungozi. Inkxaso ixhotyiswe ngegesi yokungenisa ubushushu kunye nombhobho wokuphuma ukuze kuqinisekiswe ukushisa okufanayo kwe-heater. Isiseko kunye nenkxaso ziboshwe ngamachiza kunye nomgca wokudibanisa.

I-heater ye-ceramic ingenziwa ngeekeramics ezifana ne-aluminium nitride (AlN), i-silicon nitride (Si3N4), kunye ne-alumina (Al2O3). Phakathi kwabo, i-AlN lolona khetho lungcono kwii-heaters ze-ceramic. Xa kuthelekiswa nezinye izinto, i-VET Energy's AlN ceramic inezi mpawu zilandelayo:

(1) Ukuqhuba kakuhle kwe-thermal;

(2) Ukudibanisa i-coefficient yokwandisa i-thermal kwizinto ze-silicon ze-semiconductor;

(3) Iimpawu ezilungileyo zoomatshini, ukuxhathisa okugqwesileyo kokunxiba, kunye neempawu zoomatshini ezibanzi zingcono kune-beryllium oxide kwaye ilingana ne-aluminium oxide;

(4) Iimpawu zombane ezigqwesileyo ezibanzi, ukugqunywa kombane okugqwesileyo kunye nelahleko ephantsi ye-dielectric;

(5) Ayina tyhefu kwaye ayinabungozi kokusingqongileyo.

Iphepha leDatha leMathiriyeli yeCeramic

| Into | 95% iAlumina | 99% iAlumina | Zirconia | I-silicon carbide | IsiliconNhamba | AluminiyamNhamba |

| Umbala | mhlophe | Mthubi okhanyayo | mhlophe | mnyama | mnyama | ngwevu |

| Ubuninzi (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Ukufunxwa kwamanzi | 0% | 0% | 0% | 0% | 0% | 0% |

| Ukuqina(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Amandla eFlexural (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Amandla oxinzelelo (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Imodyuli eNcinci ye-Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Umlinganiselo wePoisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| I-Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Amandla eDielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ukuxhathisa uMqulu (25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

I-VET Energy ngumvelisi oqeqeshiweyo ogxile kwi-R & D kunye nokuveliswa kwezinto eziphezulu eziphezulu ezifana negraphite, i-silicon carbide, i-quartz, kunye nonyango lwezinto eziphathekayo ezifana ne-SiC yokubeka, i-TaC yokugqoka, i-glassy carbon coating, i-pyrolytic ye-carbon coating, njl. Iimveliso zisetyenziswa ngokubanzi kwi-photovoltaic, semiconductor, amandla amatsha, isinyithi, njl.

Iqela lethu lobuchwephesha livela kumaziko aphezulu ophando lwasekhaya, linokubonelela ngezisombululo zemathiriyeli yobuchwephesha.

Izibonelelo zamandla e-VET ziquka:

• Umzi-mveliso ongowakho kunye nelebhu yobungcali;

• Amanqanaba okucoceka ahamba phambili kushishino kunye nomgangatho;

• Ixabiso elikhuphisanayo kunye nexesha lokuhanjiswa ngokukhawuleza;

• Intsebenziswano yamashishini amaninzi kwihlabathi jikelele;

Siyakwamkela ukuba ujonge umzi-mveliso wethu kunye nelabhoratri nangaliphi na ixesha!

-

Semiconductor Alumina iiseramics Insulating Insulating

-

Semiconductor Alumina iiseramikhi Wafer Carrier

-

Iiseramikhi zealumina zeSemiconductor Insulating Cover

-

I-Alumina Ceramic Semiconductor umkhono we-electrode

-

Isiko lobushushu obuphezulu kunye nokumelana nomhlwa...

-

Ukucoceka okuphezulu kwe-quartz crucible esetyenziswe kwifotovo...