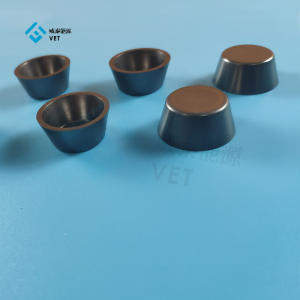

SiC Coated Graphite Halfmoon Karoloke karolo ea bohlokoa e sebelisoang lits'ebetsong tsa tlhahiso ea semiconductor, haholo-holo bakeng sa lisebelisoa tsa SiC epitaxial. Moralo oa eona oa sebopeho le thepa ea thepa e khetholla ka kotloloho boleng le katleho ea tlhahiso ea li-wafers tsa epitaxial.

Kaho ea kamore ea ho arabela:

Karolo ea halofo ea khoeli e entsoe ka likarolo tse peli, likarolo tse ka holimo le tse ka tlaase, tse kopantsoeng hammoho ho theha kamore ea khōlo e koetsoeng, e amohelang silicon carbide substrate (hangata 4H-SiC kapa 6H-SiC) 'me e finyella kholo ea epitaxial ka ho laola hantle tšimo ea phallo ea khase (joaloka motsoako oa H, C₂, H₂).

Taolo ea sebaka sa mocheso:

Setsi sa graphite se nang le bohloeki bo phahameng se kopantsoeng le coil e futhumatsang ea induction e ka boloka mocheso oa kamore e ts'oanang (ka hare ho ± 5 ° C) ka mocheso o phahameng oa 1500-1700 ° C ho netefatsa ho lumellana ha epitaxial layer thickness.

Tataiso ea phallo ea moea:

Ka ho rala boemo ba moea o kenang le oa ho tsoa (joalo ka seketsoana sa moea se lehlakoreng le moea o ka holimo oa 'mele oa sebōpi o otlolohileng), phallo ea laminar ea khase e tsamaisoang ka holim'a substrate ho fokotsa bokooa ba kholo e bakoang ke moferefere.

Lisebelisoa tsa motheo: graphite e phahameng-e hloekileng

Litlhoko tsa bohloeki:carbon content ≥99.99%, molora oa molora ≤5ppm, ho etsa bonnete ba hore ha ho na litšila tse kenngoang ho silafatsa lera la epitaxial ka mocheso o phahameng.

Melemo ea ts'ebetso:

High thermal conductivity:Thermal conductivity ka mocheso oa kamore e fihla ho 150W / (m · K), e haufi le boemo ba koporo 'me e ka fetisetsa mocheso kapele.

Coefficient e tlase ea katoloso:5×10-6/℃ (25-1000 ℃), e tsamaellanang le silicon carbide substrate (4.2×10)-6/℃), ho fokotsa ho phatloha ha lesela le bakoang ke khatello ea mocheso.

Ts'ebetso e nepahetseng:Mamello ea boholo ba ± 0.05mm e fihlelleha ka machining a CNC ho netefatsa ho tiisoa ha kamore.

Lisebelisoa tse fapaneng tsa CVD SiC le CVD TaC

| Ho roala | Tshebetso | Papiso | Tšebeliso e tloaelehileng |

| CVD-SiC | Mocheso: 1000-1200℃Khatello: 10-100 Torr | Hardness HV2500, botenya ba 50-100um, khanyetso e ntle ea oxidation (e tsitsitseng ka tlase ho 1600 ℃) | Li-furnaces tsa Universal epitaxial, tse loketseng maemo a tloaelehileng a leholimo a kang hydrogen le silane |

| CVD-TaC | Mocheso: 1600-1800℃Khatello: 1-10 Torr | Hardness HV3000, botenya 20-50um, e sa bolae ke kutu (e khona ho mamella likhase tse senyang tse kang HCl, NH₃, joalo-joalo) | Libaka tse senyang haholo (tse kang GaN epitaxy le etching equipment), kapa mekhoa e khethehileng e hlokang mocheso o phahameng haholo oa 2600°C. |

VET Energy ke moetsi ea hloahloa o shebaneng le R&D le tlhahiso ea lisebelisoa tse tsoetseng pele tse phahameng joalo ka graphite, silicon carbide, quartz, hammoho le kalafo ea thepa e kang SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, joalo-joalo Lihlahisoa li sebelisoa haholo ho photovoltaic, semiconductor, matla a macha, metallurgy, metallurgy, metalc.

Sehlopha sa rona sa tekheniki se tsoa litsing tse phahameng tsa lipatlisiso tsa lapeng, se ka u fa litharollo tsa lisebelisoa tse eketsehileng bakeng sa hau.

Melemo ea Matla a VET e kenyelletsa:

• Femetheri le laboratori ea litsebi;

• Maemo a bohloeki a etelletseng pele indastering le boleng;

• Theko ea tlhōlisano & Nako ea ho fana ka potlako;

• Litšebelisano tse ngata tsa indasteri lefatšeng ka bophara;

Re u amohela ho bona feme le laboratori ea rona ka nako efe kapa efe!

-

Khabone ea Khalase ea Khalase ea Boleng bo Phahameng e hanyetsanang le kutu ...

-

Wafer susceptor e nang le TaC coating bakeng sa G5 G10

-

Karolo ea ho roala ha fektheri ea tantalum carbide

-

Silicon Carbide Coated Graphite Susceptor bakeng sa L...

-

Karolo ea halofo ea khoeli e nang le seaparo sa Tantalum Carbide

-

Porous Tantalum Carbide Coated Barrel