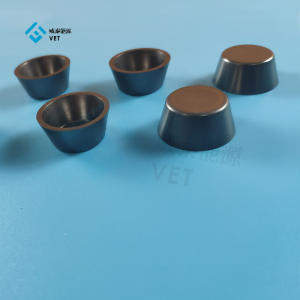

I-SiC Coated Graphite Halfmoon Partiyingxenye ebalulekile esetshenziswa ezinqubweni zokukhiqiza ze-semiconductor, ikakhulukazi kumishini ye-SiC epitaxial. Idizayini yayo yesakhiwo kanye nempahla yezinto ezibonakalayo inquma ngokuqondile ikhwalithi nokusebenza kahle kokukhiqiza kwama-epitaxial wafers.

Ukwakhiwa kwegumbi lokusabela:

Ingxenye yenyanga eyingxenye yakhiwe izingxenye ezimbili, izingxenye ezingenhla nezingaphansi, eziboshelwe ndawonye ukuze zenze igumbi lokukhula elivaliwe, elihlalisa i-silicon carbide substrate (imvamisa i-4H-SiC noma i-6H-SiC) futhi ifinyelela ukukhula kongqimba lwe-epitaxial ngokulawula ngokuqondile insimu yokugeleza kwegesi (njenge-H₂₂ ne-H₂, H₂ kanye nengxube ye-H₂).

Ukulawulwa kwezinga lokushisa:

Isisekelo se-graphite esiphezulu esihlanzekile esihlangene nekhoyili yokushisa yokungeniswa singagcina ukushisa kwegumbi (ngaphakathi kwe-± 5 ° C) ekushiseni okuphezulu kwe-1500-1700 ° C ukuze kuqinisekiswe ukuhambisana kogqinsi lwe-epitaxial layer.

Isiqondiso sokugeleza komoya:

Ngokuklama indawo yokungena komoya kanye nokuphumayo (okufana nendawo yokungena komoya eseceleni kanye nendawo yokukhipha umoya ephezulu yomzimba wesithando somlilo ovundlile), ukugeleza kwe-laminar yegesi esabelayo kuqondiswa endaweni engaphansi ukuze kuncishiswe amaphutha okukhula okubangelwa isiyaluyalu.

Izinto eziyisisekelo: i-graphite ephezulu

Izidingo zokuhlanzeka:okuqukethwe kwekhabhoni ≥99.99%, okuqukethwe komlotha ≤5ppm, ukuze kuqinisekiswe ukuthi akukho ukungcola okutholayo ukungcolisa ungqimba lwe-epitaxial emazingeni okushisa aphezulu.

Izinzuzo zokusebenza:

High thermal conductivity:I-thermal conductivity ekamelweni lokushisa ifinyelela ku-150W/(m・K), eseduze nezinga lethusi futhi ingadlulisela ukushisa ngokushesha.

I-coefficient yokunweba ephansi:5×10-6/℃ (25-1000℃), ukufanisa i-silicon carbide substrate (4.2×10-6/℃), inciphisa ukuqhekeka kwentonga ebangelwa ukucindezeleka okushisayo.

Ukucubungula ukunemba:Ukubekezelela okulinganayo okungu-±0.05mm kufinyelelwa ngomshini we-CNC ukuze kuqinisekiswe ukuvalwa kwegumbi.

Izinhlelo zokusebenza ezihlukene ze-CVD SiC ne-CVD TaC

| Ukugqoka | Inqubo | Ukuqhathanisa | Uhlelo lokusebenza olujwayelekile |

| I-CVD-SiC | Izinga lokushisa: 1000-1200℃Ingcindezi: 10-100 Torr | Ukuqina kwe-HV2500, ukujiya okungu-50-100um, ukumelana okuhle kakhulu kwe-oxidation (kuzinzile ngezansi kwe-1600 ℃) | I-Universal epitaxial furnaces, efanelekile emkhathini ovamile njenge-hydrogen ne-silane |

| I-CVD-TaC | Izinga lokushisa: 1600-1800℃Ingcindezi: 1-10 Torr | Ukuqina kwe-HV3000, ukujiya okungu-20-50um, ukumelana nokugqwala ngokweqile (kungakwazi ukumelana namagesi agqwalayo njenge-HCl, NH₃, njll.) | Izindawo ezigqwala kakhulu (ezifana ne-GaN epitaxy ne-etching equipment), noma izinqubo ezikhethekile ezidinga izinga lokushisa eliphezulu elingu-2600°C |

I-VET Energy ingumkhiqizi ochwepheshe ogxile ku-R&D kanye nokukhiqizwa kwezinto ezithuthukisiwe ezisezingeni eliphezulu njengegraphite, i-silicon carbide, i-quartz, kanye nokwelashwa okubonakalayo okufana ne-SiC coating, i-TaC coating, i-glassy carbon coating, i-pyrolytic carbon coating, njll. Imikhiqizo isetshenziswa kabanzi ku-photovoltaic, i-semiconductor, amandla amasha, i-metallurgy, njll.

Ithimba lethu lezobuchwepheshe livela ezikhungweni eziphezulu zocwaningo lwasekhaya, lingakunikeza izixazululo zempahla echwepheshile.

Izinzuzo ze-VET Energy zihlanganisa:

• Ifekthri kanye nelabhorethri yochwepheshe;

• Amazinga okuhlanzeka okuhamba phambili embonini kanye nekhwalithi;

• Intengo yokuncintisana nesikhathi sokulethwa okusheshayo;

• Ubambiswano lwezimboni eziningi emhlabeni wonke;

Siyakwamukela ukuthi uvakashele imboni yethu kanye nelabhorethri nganoma yisiphi isikhathi!

-

Ikhabhoni Yengilazi Yekhwalithi Ephakeme Ekwazi ukumelana nokugqwala ...

-

I-wafer susceptor ene-TaC coating ye-G5 G10

-

Ingxenye ye-tantalum carbide eyenziwe ngezifiso ifektri

-

I-Silicon Carbide Coated Graphite Susceptor ye-L...

-

Ingxenye yenyanga ene-Tantalum Carbide

-

I-Porous Tantalum Carbide Coated Barrel