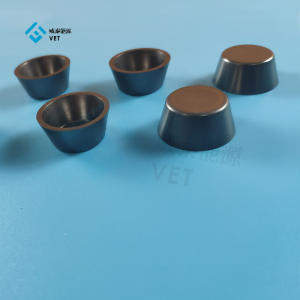

Qaybta SiC Dahaarka Garaafka Halfmoonwaa qayb muhiim ah oo loo isticmaalo hababka wax soo saarka semiconductor, gaar ahaan qalabka SiC epitaxial. Naqshaddeeda qaab-dhismeedkeeda iyo sifooyinka walxaha ayaa si toos ah u go'aamiya tayada iyo waxtarka wax soo saarka ee wafers epitaxial.

Dhismaha qolka falcelinta:

Qaybta dayaxa badhku waxay ka kooban tahay laba qaybood, qaybaha sare iyo hoose, kuwaas oo la isku duubay si ay u sameeyaan qolka koritaanka xiran, kaas oo daboolaya substrate-ka silikoon carbide (sida caadiga ah 4H-SiC ama 6H-SiC) oo gaadha kobaca lakabka epitaxial iyadoo si sax ah loo xakameynayo gaaska socodka gaaska (sida isku dhafka SiH₄, H₄, C).

Xeerarka goobta heerkulka:

Saldhigga garaafka nadiifka ah ee nadiifka ah ee lagu daray gariiradda kuleyliyaha induction wuxuu ilaalin karaa isku mid ahaanshaha heerkulka qolka (± 5 ° C) heerkul sare oo ah 1500-1700 ° C si loo hubiyo joogteynta dhumucda lakabka epitaxial.

Hagida socodka hawada:

Iyadoo la naqshadeynayo booska hawada laga soo galo iyo ka-soo-baxa (sida hawada dhinaca hawada laga soo galo iyo hawada sare ee hawada foornada jiifka ah), socodka gaaska fal-celinta ee laminarka ayaa lagu hagayaa dusha sare ee substrate si loo yareeyo cilladaha koritaanka ee ay keento qulqulo.

Qalabka saldhigga ah: graphite-nadiifinta sare

Shuruudaha nadiifnimada:Kaarboonka ≥99.99%, ka kooban dambas ≤5ppm, si loo hubiyo in wax wasakh ah aysan soo degdegin si ay u wasakhayso lakabka epitaxial heerkulka sare.

Faa'iidooyinka waxqabadka:

Dhaqdhaqaaqa kulaylka sare:Heerkulka kulaylka ee heerkulka qolka wuxuu gaaraa 150W / (m・K), kaas oo ku dhow heerka naxaasta oo si dhakhso ah u wareejin kara kulaylka.

Isku xidhka balaadhinta hoose:5×10-6/ ℃ (25-1000 ℃), oo ku habboon substrate carbide silicon (4.2 × 10)-6/ ℃), yaraynta dildilaaca dahaarka ay keento cadaadiska kulaylka.

Xaqiijinta habaynta:Dulqaadka cabbirka ± 0.05mm waxaa lagu gaaraa mashiinnada CNC si loo hubiyo xiridda qolka.

Codsiyada kala duwan ee CVD SiC iyo CVD TaC

| Dahaarka | Habka | Isbarbardhigga | Codsiga caadiga ah |

| CVD-SiC | Heerkulka: 1000-1200 ℃ Cadaadis: 10-100 Torr | Hardness HV2500, dhumucdiisuna waxay tahay 50-100um, iska caabin oksaydhka heer sare ah (xasillooni ka hooseeya 1600 ℃) | Foornooyinka epitaxial Universal, oo ku habboon jawiga caadiga ah sida hydrogen iyo silane |

| CVD-TaC | Heerkulka: 1600-1800 ℃ Cadaadis: 1-10 Torr | Hardness HV3000, dhumucdiisuna waa 20-50um, aad u adkaysta daxalka (waxay u adkeysan kartaa gaasaska daxalka ah sida HCl, NH₃, iwm.) | Deegaan aad u daxalaysa (sida GaN epitaxy iyo qalabka etching), ama hababka gaarka ah ee u baahan heerkul aad u sarreeya oo ah 2600°C |

VET Energy waa saaraha xirfadeed diiradda on R & D iyo wax soo saarka ee-dhamaadka sare qalab horumarsan sida graphite, silikon carbide, quartz, iyo sidoo kale daaweynta alaabta sida daahan SiC, daahan TaC, daahan carbon galaas, daahan carbon pyrolytic, iwm Alaabooyinka waxaa si ballaaran loo isticmaalaa in photovoltaic, semiconductor, tamarta cusub, metallurgy, iwm.

Kooxdayada farsamo waxay ka yimaadaan hay'adaha cilmi-baarista gudaha ee ugu sarreeya, waxay ku siin karaan xalal qalab xirfadeed oo dheeraad ah adiga.

Faa'iidooyinka tamarta VET waxaa ka mid ah:

• Warshad iyo shaybaadhka xirfadlayaasha ah;

• Heerarka nadiifka ah ee hogaaminaya warshadaha iyo tayada;

• Qiimaha tartanka & wakhtiga keenista degdega ah;

• Iskaashiyo badan oo warshadeed oo caalami ah;

Waxaan kugu soo dhawaynaynaa inaad booqato warshadeena iyo shaybaadhka wakhti kasta!