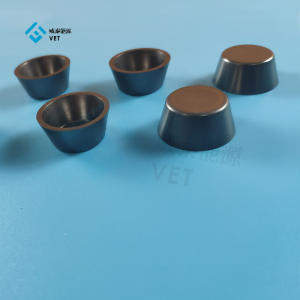

SiC Coated Graphite Halfmoon Partyog ib feem tseem ceeb siv nyob rau hauv semiconductor manufacturing txheej txheem, tshwj xeeb tshaj yog rau SiC epitaxial khoom. Nws cov qauv tsim thiab cov khoom siv ncaj qha txiav txim siab qhov zoo thiab kev ua haujlwm ntawm epitaxial wafers.

Reaction Chamber Kev tsim kho:

Lub hli ib nrab yog tsim los ntawm ob ntu, sab sauv thiab hauv qab, uas yog buckled ua ke los tsim lub kaw kev loj hlob chamber, uas haum rau silicon carbide substrate (feem ntau 4H ₈SiC los yog 6H-SiC) thiab ua tiav epitaxial txheej loj hlob los ntawm precisely tswj cov pa roj ntws (xws li ib tug sib tov ntawm ₈ ₈ ₈SiC los yog 6H-SiC).

Kev tswj qhov kub thiab txias:

Lub high-purity graphite puag ua ke nrog induction cua sov kauj tuaj yeem tswj lub chamber kub sib xws (hauv ± 5 ° C) ntawm qhov kub ntawm 1500-1700 ° C kom ntseeg tau tias qhov sib xws ntawm epitaxial txheej thickness.

Airflow kev taw qhia:

Los ntawm kev tsim txoj hauj lwm ntawm cov cua nkag thiab qhov hluav taws xob (xws li sab cua nkag thiab sab saum toj cua qhov hluav taws xob ntawm kab rov tav rauv lub cev), cov tshuaj tiv thaiv roj laminar ntws yog coj los ntawm lub substrate nto kom txo qhov kev loj hlob tsis xws luag los ntawm turbulence.

Cov khoom siv hauv paus: high-purity graphite

Purity xav tau:Cov ntsiab lus carbon ≥99.99%, cov ntsiab lus tshauv ≤5ppm, kom ntseeg tau tias tsis muaj impurities yog precipitated kom paug cov epitaxial txheej ntawm kub.

Kev ua tau zoo zoo:

High thermal conductivity:Lub thermal conductivity ntawm chav tsev kub nce mus txog 150W / (m・K), uas yog ze rau qib tooj liab thiab tuaj yeem hloov tau sai.

Tsawg expansion coefficient:5 × 10-6/ ℃ (25-1000 ℃), sib piv cov silicon carbide substrate (4.2 × 10-6/ ℃), txo qhov tawg ntawm txheej txheej los ntawm thermal stress.

Kev ua kom raug:Qhov ntev ntev ntawm ± 0.05mm yog ua tiav los ntawm CNC machining los xyuas kom meej lub sealing ntawm lub chamber.

Kev sib txawv ntawm CVD SiC thiab CVD TaC

| Txheej | Txheej txheem | Kev sib piv | Tej daim ntawv thov |

| CVD-SiC | Kub: 1000-1200 ℃ Siab: 10-100 Torr | Hardness HV2500, thickness 50-100um, oxidation zoo heev (ruaj khov hauv qab 1600 ℃) | Universal epitaxial furnaces, haum rau cov pa cua xws li hydrogen thiab silane |

| CVD-TaC | Kub: 1600-1800 ℃ Siab: 1-10 Torr | Hardness HV3000, thickness 20-50um, tsis tshua muaj corrosion-resistant (tuaj yeem tiv taus corrosive gases xws li HCl, NH₃, thiab lwm yam) | Ib puag ncig corrosive heev (xws li GaN epitaxy thiab cov khoom siv etching), los yog cov txheej txheem tshwj xeeb uas yuav tsum muaj qhov kub thiab txias ntawm 2600 ° C |

VET Energy yog cov chaw tsim khoom lag luam tsom rau R&D thiab tsim cov khoom siv high-end xws li graphite, silicon carbide, quartz, nrog rau cov khoom siv kho mob xws li SiC txheej, TaC txheej, iav carbon txheej, pyrolytic carbon txheej, thiab lwm yam. Cov khoom siv dav siv hauv photovoltaic, semiconductor, tshiab zog, metalclurgy.

Peb pab neeg ua haujlwm los ntawm cov tsev kawm tshawb fawb saum toj kawg nkaus hauv tebchaws, tuaj yeem muab cov ntaub ntawv tshaj lij tshaj lij rau koj.

VET Energy zoo muaj xws li:

• Tus kheej lub Hoobkas thiab kev kuaj xyuas;

• Kev lag luam-ua purity theem thiab zoo;

• Tus nqi sib tw & Lub sijhawm xa khoom sai;

• Ntau lub koom haum kev lag luam thoob ntiaj teb;

Peb zoo siab tos txais koj tuaj xyuas peb lub Hoobkas thiab chav kuaj txhua lub sijhawm!