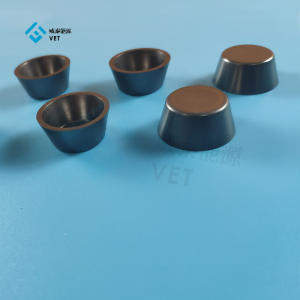

Akụkụ SiC mkpuchi graphite Halfmoonbụ isi akụrụngwa eji na usoro nrụpụta semiconductor, ọkachasị maka akụrụngwa epitaxial SiC. Nhazi ya na ihe onwunwe ya na-ekpebi ịdị mma na nrụpụta ọrụ nke epitaxial wafers ozugbo.

Owuwu ụlọ mmeghachi omume:

Akụkụ nke ọkara ọnwa mejupụtara akụkụ abụọ, akụkụ nke elu na nke ala, nke a na-ejikọta ọnụ iji mepụta ụlọ uto mechiri emechi, nke na-anabata mkpụrụ osisi silicon carbide (na-abụkarị 4H-SiC ma ọ bụ 6H-SiC) wee nweta uto epitaxial oyi akwa site n'ịchịkwa oke ikuku gas (dị ka ngwakọta nke SiH₄, H₄, C).

Iwu mpaghara okpomọkụ:

Ntọala graphite dị elu nke dị elu jikọtara ya na eriri ọkụ induction nwere ike idowe ịdị n'otu ụlọ ahụ (n'ime ± 5 ° C) na okpomọkụ dị elu nke 1500-1700 ° C iji hụ na nkwụsi ike nke oyi akwa epitaxial.

Ntuziaka ikuku:

Site n'ichepụta ọnọdụ nke ntinye ikuku na ntinye (dị ka oghere ikuku dị n'akụkụ na elu ikuku nke ahụ ọkụ kwụ ọtọ), a na-eduzi mmeghachi omume gas laminar site na ala mkpụrụ iji belata nrụrụ uto nke ọgba aghara kpatara.

Ihe ndabere: graphite dị ọcha

Achọrọ ịdị ọcha:carbon ọdịnaya ≥99.99%, ash ọdịnaya ≤5ppm, iji hụ na ọ dịghị adịghị ọcha na-akpalite imerụ epitaxial oyi akwa na elu okpomọkụ.

Uru arụmọrụ:

Nrụpụta ọkụ dị elu:Thermal conductivity na ụlọ okpomọkụ ruru 150W / (m・K), nke dị nso na larịị nke ọla kọpa na ike ngwa ngwa nyefee okpomọkụ.

Ọnụọgụ mgbasawanye dị ala:5×10-6/ ℃ (25-1000 ℃), dakọtara na silicon carbide mkpụrụ (4.2×10).-6/ ℃), na-ebelata mgbawa nke mkpuchi nke nrụgide okpomọkụ kpatara.

Nhazi izizi:A na-enweta nnabata akụkụ nke ± 0.05mm site na igwe CNC iji hụ na akara nke ụlọ ahụ.

Ngwa dị iche iche nke CVD SiC na CVD TaC

| Mkpuchi | Usoro | Ntụnyere | Ngwa a na-ahụkarị |

| CVD-SiC | Okpomọkụ: 1000-1200 ℃ Nrụgide: 10-100 Torr | Isi ike HV2500, ọkpụrụkpụ 50-100um, magburu onwe oxidation eguzogide (kwụsi ike n'okpuru 1600 ℃) | Igwe ọkụ epitaxial zuru ụwa ọnụ, dabara maka ikuku ikuku dị ka hydrogen na silane |

| CVD-TaC | Okpomọkụ: 1600-1800 ℃ Nrụgide: 1-10 Torr | HV3000 siri ike, ọkpụrụkpụ 20-50um, na-eguzogide oke corrosion (nwere ike iguzogide gas na-emebi emebi dịka HCl, NH₃, wdg) | Gburugburu ebe na-emebi emebi (dị ka GaN epitaxy na etching equipment), ma ọ bụ usoro pụrụ iche chọrọ okpomọkụ dị elu nke 2600°C |

VET Energy bụ ọkachamara emeputa na-elekwasị anya na R & D na mmepụta nke elu-ọgwụgwụ elu ihe dị ka graphite, silicon carbide, quartz, nakwa dị ka ihe ọgwụgwọ dị ka SiC mkpuchi, TaC mkpuchi, glassy carbon mkpuchi, pyrolytic carbon mkpuchi, wdg The ngwaahịa na-ọtụtụ-eji na fotovoltaic, semiconductor, ọhụrụ ume, metallurgy, wdg.

Anyị oru otu si n'elu ụlọ nnyocha ụlọ ọrụ, nwere ike na-enye ndị ọzọ ọkachamara ihe ngwọta maka gị.

Uru VET Energy gụnyere:

• Ụlọ ọrụ mmepụta ihe na ụlọ nyocha ọkachamara;

• Ụlọ ọrụ na-eduga ọkwa dị ọcha na ịdị mma;

• Ọnụ ahịa asọmpi & oge nnyefe ngwa ngwa;

• Mmekọrịta ọtụtụ ụlọ ọrụ n'ụwa nile;

Anyị na-anabata gị ka vist anyị factory na laabu n'oge ọ bụla!