I-Ceramic Wafer Heater i-AlN Alumina Heating Element

Ekwenziweni kwama-semiconductor, ama-wafers adinga ukucutshungulwa ngezinqubo ezahlukahlukene, njengokufakwa kwefilimu emincane, etching, njll. Kulezi zixhumanisi, ama-wafers adinga ukushiselwa ezingeni elithile lokushisa, futhi kunezidingo eziqinile zamazinga okushisa, ngoba ukufana kwezinga lokushisa kunomthelela obaluleke kakhulu ekuvuthweni komkhiqizo, futhi izingxenye zokushisisa zibalulekile.

I-heater kagesiisetshenziswa ngokuqondile ekamelweni lenqubo futhi ithintana ngqo ne-wafer. Abagcini nje ngokuthwala i-wafer, kodwa futhi baqinisekisa ukuthi i-wafer ithola izinga lokushisa elizinzile nelifanayo. Ziyizingxenye ezibalulekile kumishini yokubeka ifilimu emincane ye-semiconductor!

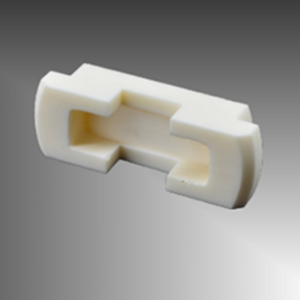

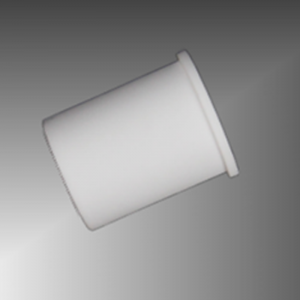

I-ceramic heater ihlanganisa isisekelo se-ceramic esisekela i-wafer kanye nomzimba osekelayo oyisilinda ohlangothini olungemuva olusekelayo. Ngaphezu kwesici sokumelana (ingqimba yokushisa) yokushisa, kukhona nama-electrode amafrikhwensi omsakazo (ungqimba lwe-RF) ngaphakathi noma ngaphezulu kwesisekelo se-ceramic. Ukuze kuzuzwe ukushisa nokupholisa ngokushesha, ubukhulu besisekelo se-ceramic kufanele bube buncane, kodwa buncane kakhulu futhi buzonciphisa ukuqina.

Ukusekelwa kwe-heater ye-ceramic ngokuvamile kwenziwa nge-ceramic material ene-coefficient yokwandisa okushisayo efana nesisekelo. I-heater ithatha isakhiwo esiyingqayizivele se-shaft joint bottom ukuvikela amatheminali nezintambo emiphumeleni ye-plasma namagesi amakhemikhali abolayo. Ukwesekwa kufakwe igesi yokudlulisa ukushisa kanye nepayipi lokuphuma ukuze kuqinisekiswe izinga lokushisa elifanayo le-heater. Isisekelo nokwesekwa kuhlanganiswe ngamakhemikhali ngesendlalelo sokubopha.

I-ceramic heater ingenziwa ngezitsha zobumba ezifana ne-aluminium nitride (AlN), i-silicon nitride (Si3N4), ne-alumina (Al2O3). Phakathi kwabo, i-AlN iyisinqumo esingcono kakhulu sama-heaters e-ceramic. Uma iqhathaniswa nezinye izinto, i-AlN ceramic ye-VET Energy inezici ezilandelayo:

(1) I-thermal conductivity enhle;

(2) Fanisa i-coefficient yokwandisa okushisayo kuzinto ze-silicon ze-semiconductor;

(3) Izakhiwo ezinhle zemishini, ukumelana nokugqokwa okuhle kakhulu, kanye nezakhiwo zemishini ezibanzi zingcono kune-beryllium oxide futhi ilingana ne-aluminium oxide;

(4) Izakhiwo zikagesi ezinhle kakhulu ezibanzi, ukufakwa kukagesi okuhle kakhulu kanye nokulahlekelwa okuncane kwe-dielectric;

(5) Ayinabuthi futhi ayihambisani nemvelo.

Ishidi Ledatha Lezinto Zobumba

| Into | 95% Alumina | 99% Alumina | I-Zirconia | I-silicon carbide | I-siliconNhamba | I-AluminiumNhamba |

| Umbala | mhlophe | Okuphuzi okukhanyayo | mhlophe | mnyama | mnyama | impunga |

| Ukuminyana (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Ukumuncwa Amanzi | 0% | 0% | 0% | 0% | 0% | 0% |

| Ukuqina(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Amandla e-Flexural (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Amandla Acindezelayo (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| I-Young's Modulus Of Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa |

| Isilinganiso sikaPoisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| I-Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Amandla e-Dielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ukungazweli Ivolumu(25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

I-VET Energy ingumkhiqizi ochwepheshile ogxile ku-R&D nasekukhiqizeni izinto ezithuthukile ezisezingeni eliphezulu njengegraphite, i-silicon carbide, i-quartz, kanye nokwelapha okuphathekayo okufana ne-SiC coating, i-TaC coating, i-glassy carbon coating, i-pyrolytic carbon coating, njll. Imikhiqizo isetshenziswa kabanzi ku-photovoltaic, semiconductor, amandla amasha njll.

Ithimba lethu lezobuchwepheshe livela ezikhungweni eziphezulu zocwaningo lwasekhaya, lingakunikeza izixazululo zempahla echwepheshile.

Izinzuzo ze-VET Energy zihlanganisa:

• Ifekthri kanye nelabhorethri yochwepheshe;

• Amazinga okuhlanzeka okuhamba phambili embonini kanye nekhwalithi;

• Intengo yokuncintisana nesikhathi sokulethwa okusheshayo;

• Ubambiswano lwezimboni eziningi emhlabeni wonke;

Siyakwamukela ukuthi uvakashele imboni yethu kanye nelabhorethri nganoma yisiphi isikhathi!

-

Semiconductor Alumina ceramics Insulating Cover

-

ISemiconductor Alumina Ceramics Wafer Carrier

-

Ikhava ye-Alumina ceramics Semiconductor Insulating Cover

-

Umkhono we-Alumina Ceramic Semiconductor electrode

-

Izinga lokushisa eliphezulu ngokwezifiso nokumelana nokugqwala...

-

I-quartz crucible ephezulu esetshenziswe ku-photovo...