Ceramic Wafer Heater AlN Alumina Heating Element

In semiconductor manufacturing, wafers need to be processed in various processes, such as thin film deposition, etching, etc. In these links, the wafers need to be heated to a certain temperature, and there are strict requirements for the temperature, because the uniformity of temperature has a very important impact on the product yield, and heating components are indispensable.

Ceramic heater is directly applied to the process chamber and are in direct contact with the wafer. They not only carry the wafer, but also ensure that the wafer obtains a stable and uniform process temperature. They are key components in semiconductor thin film deposition equipment!

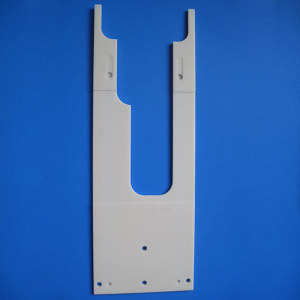

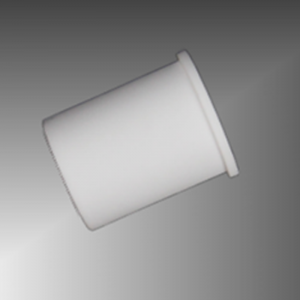

The ceramic heater includes a ceramic base that supports the wafer and a cylindrical support body on the back side that supports it. In addition to the resistance element (heating layer) for heating, there are also radio frequency electrodes (RF layer) inside or on the surface of the ceramic base. In order to achieve rapid heating and cooling, the thickness of the ceramic base should be thin, but too thin will also reduce the rigidity.

The support of the ceramic heater is generally made of ceramic material with a thermal expansion coefficient similar to that of the base. The heater adopts a unique structure of a shaft joint bottom to protect the terminals and wires from the effects of plasma and corrosive chemical gases. The support is equipped with a heat transfer gas inlet and outlet pipe to ensure uniform temperature of the heater. The base and the support are chemically bonded with a bonding layer.

The ceramic heater can be made of ceramics such as aluminum nitride (AlN), silicon nitride (Si3N4), and alumina (Al2O3). Among them, AlN is the best choice for ceramic heaters. Compared with other materials, VET Energy's AlN ceramic has the following characteristics:

(1) Good thermal conductivity;

(2) Matched thermal expansion coefficient to semiconductor silicon materials;

(3) Good mechanical properties, excellent wear resistance, and comprehensive mechanical properties are better than beryllium oxide and equivalent to aluminum oxide;

(4) Excellent comprehensive electrical properties, excellent electrical insulation and low dielectric loss;

(5) Non-toxic and environmentally friendly.

Data Sheet of Ceramic Materials

| Item | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | Silicon Nitride | Aluminum Nitride |

| Colour | white | Light yellow | white | black | black | gray |

| Density (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 |

| Water Absorption | 0% | 0% | 0% | 0% | 0% | 0% |

| Hardness(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - |

| Flexural Strength (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa |

| Compressive Strength (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - |

| Young's Modulus Of Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310~350GPa |

| Poisson's Ratio | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C |

| Dielectric Strength | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Volume Resistivity(25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm |

VET Energy is a professional manufacturer focusing on the R&D and production of high-end advanced materials such as graphite, silicon carbide, quartz, as well as the material treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc. The products are widely used in photovoltaic, semiconductor, new energy, metallurgy, etc..

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

VET Energy advantages includes:

• Own factory and professional laboratory;

• Industry-leading purity levels and quality;

• Competive price & Fast delivery time;

• Multiple industry partnerships worldwide;

We welcome you to vist our factory and laboratory at any time!