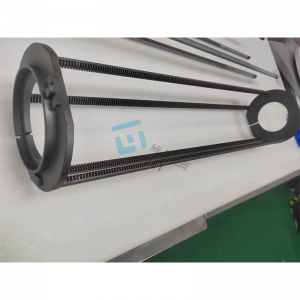

Porous Tantalum Carbide Coated Graphite Ring

Porous tantalum carbide (TaC) coated graphite is a key material developed specifically for the high-temperature, highly corrosive environments of semiconductor manufacturing. Its substrate is high-purity isostatic graphite, coated with a uniformly porous tantalum carbide coating using chemical vapor deposition (CVD). TaC has an extremely high hardness (9-10 on the Mohs scale) and a melting point of 3880°C. Combined with graphite's excellent thermal stability and lightweight properties, this material combines high-temperature strength with resistance to chemical attack and thermal shock, making it an ideal choice for semiconductor process equipment operating under extreme conditions.

Advantages of Porous Tantalum Carbide Graphite:

1. Ultra-High Corrosion Resistance

-TaC is chemically inert, effectively resisting corrosion from halogens such as fluorine and chlorine, significantly extending equipment life.

-The porous structure increases the coating's surface area, forming a more robust protective barrier and reducing the risk of particle shedding.

2. Excellent High-Temperature Stability

-With a melting point approaching 4000°C, it can operate for extended periods in vacuum or inert atmospheres exceeding 2500°C.

-The thermal expansion coefficient of the coating is highly matched to that of the graphite, preventing cracking and delamination caused by thermal cycling.

3. High Purity and Low Contamination

-Using semiconductor-grade raw materials and processes, the metal impurity content is extremely low, significantly reducing the risk of wafer contamination.

-The surface is dense and chemically stable, reducing particle generation and meeting stringent cleanroom standards.

4. Custom Design

Complex shapes can be produced according to customer drawings, and porosity and coating thickness can be controlled to achieve optimal gas flow and thermal conductivity.

5. Long Lifespan And Low Maintenance Cost

The extremely high corrosion and wear resistance of porous TaC coatings increases component life by 3-5 times compared to traditional graphite, reducing replacement frequency and maintenance costs.

Main Applications

1. Core components for wafer manufacturing

- Reaction chamber liners, baffles, and shower-head for CVD/ALD equipment

- PVD target supports

- High-temperature process components for diffusion, oxidation, annealing, and other processes

2. Chemical vapor deposition systems

- Protecting key components in highly corrosive environments (such as fluorides and chlorides) during the process

3. Other high-temperature corrosive environments

- Suitable for chemical gas purification, specialized heat treatment furnaces, and other applications.

VET Energy is a professional manufacturer focusing on the R&D and production of high-end advanced materials such as graphite, silicon carbide, quartz, as well as the material treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc. The products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc..

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

VET Energy advantages includes:

• Own factory and professional laboratory;

• Industry-leading purity levels and quality;

• Competive price & Fast delivery time;

• Multiple industry partnerships worldwide;

We welcome you to vist our factory and laboratory at any time!