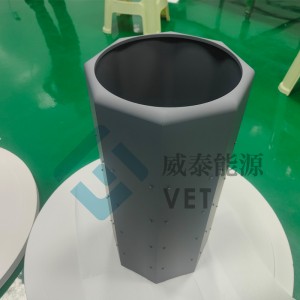

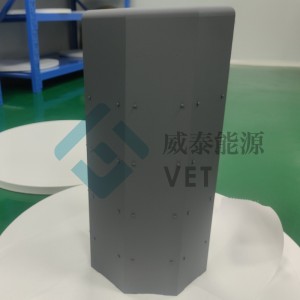

Lub cev susceptoryog ib qho tseem ceeb hauv cov txheej txheem semiconductor epitaxial loj hlob xws li MOCVD, MBE, CVD. Nws yog tsuas yog siv los nqa wafers nyob rau hauv high-temperature cov tshuaj tiv thaiv chambers thiab muab ib tug uniform thiab ruaj khov thermal teb ib puag ncig los xyuas kom meej meej deposition ntawm epitaxial txheej (xws li GaN, SiC, thiab lwm yam). Nws lub luag haujlwm tseem ceeb yog ua kom muaj qhov sib xws ntawm qhov kub thiab txias ntawm qhov kub thiab txias los ntawm kev tswj xyuas qhov kub thiab txias, yog li ua kom lub thickness, doping concentration, thiab crystal qauv uniformity ntawm epitaxial nyias zaj duab xis.

Peb siv peb patented technology los ua tuscev susceptornrog tsis tshua muaj siab purity, zoo txheej uniformity thiab ib tug zoo heev kev pab cuam lub neej, raws li zoo raws li cov tshuaj tiv thaiv thiab thermal stability.

VET Zog siv siab purity graphite nrog CVD-SiC txheej los txhim kho cov tshuaj stability:

1. High purity graphite khoom

High thermal conductivity: thermal conductivity ntawm graphite yog peb npaug ntawm silicon, uas tuaj yeem hloov cov cua sov los ntawm cov cua sov mus rau wafer thiab txo lub sij hawm cua sov.

Mechanical zog: Isostatic siab graphite ntom ≥ 1.85 g / cm ³, muaj peev xwm tiv taus qhov kub siab tshaj 1200 ℃ yam tsis muaj deformation.

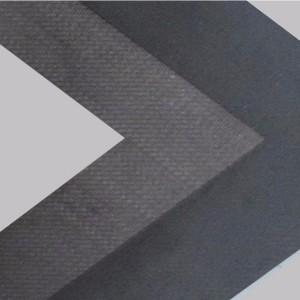

2. CVD SiC txheej

A β - SiC txheej yog tsim nyob rau saum npoo ntawm graphite los ntawm cov tshuaj vapor deposition (CVD), nrog ib tug purity ntawm ≥ 99.99995%, lub uniformity yuam kev ntawm txheej thickness yog tsawg tshaj li ± 5%, thiab lub nto roughness yog tsawg dua Ra0.5um.

3. Kev txhim kho kev ua haujlwm:

Corrosion tsis kam: tuaj yeem tiv taus cov roj corrosive siab xws li Cl2, HCl, thiab lwm yam, tuaj yeem txuas ntxiv lub neej ntawm GaN epitaxy los ntawm peb zaug hauv NH3 ib puag ncig.

Thermal stability: Lub coefficient ntawm thermal expansion (4.5 × 10-6 / ℃) sib tw graphite kom tsis txhob txheej tawg los ntawm qhov kub thiab txias.

Hardness thiab Wear Resistance: Vickers hardness ncav cuag 28 GPa, uas yog 10 npaug siab dua graphite thiab tuaj yeem txo qhov kev pheej hmoo ntawm wafer khawb.

| CVD SiC薄膜基本物理性能 Basic Physical Properties ntawm CVD SiCtxheej | |

| 性质 / Khoom | 典型数值 / Tus nqi |

| 晶体结构 / Crystal Structure | FCC β theem多晶, 主要为(111) Ib |

| 密度 / Ceev | 3.21 g / cm³ |

| 硬度 / Hardness | 2500 维氏硬度 (500g load) |

| 晶粒大小 / Grain SiZe | 2 ~ 10 hli |

| 纯度 / Tshuaj Purity | 99.99995% |

| Cov duab / Kub Muaj Peev Xwm | 6 40j kg-1· K-1 |

| 升华温度 / Sublimation kub | 2700 ℃ |

| 抗弯强度 / Flexural zog | 415 MPa RT 4-point |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt khoov, 1300 ℃ |

| 导热系数 / KublKev coj ua | 300 Wm-1· K-1 |

| 热膨胀系数 / Thermal Expansion (CTE) | 4.5 × 10-6K-1 |

Ningbo VET Energy Technology Co., Ltd yog lub tuam txhab high-tech tsom mus rau kev txhim kho thiab tsim cov khoom siv high-end, cov ntaub ntawv thiab thev naus laus zis suav nrog graphite, silicon carbide, ceramics, kev kho saum npoo zoo li SiC txheej, TaC txheej, iav carbon txheej, pyrolytic carbon txheej, thiab lwm yam., cov khoom no tau siv dav hauv photovoltaic, zog, semiconductor, metallurgy, tshiab.

Peb pab pawg kws tshaj lij los ntawm cov tsev kawm tshawb fawb sab saum toj hauv tebchaws, thiab tau tsim ntau yam patented technologies los xyuas kom meej cov khoom ua tau zoo thiab zoo, kuj tuaj yeem muab cov neeg siv khoom nrog cov khoom siv kev daws teeb meem.